DOPAG presents new drum pumps for lubricants, adhesives and sealants

Users benefit from customised configuration, user-friendly operation and high production reliability.

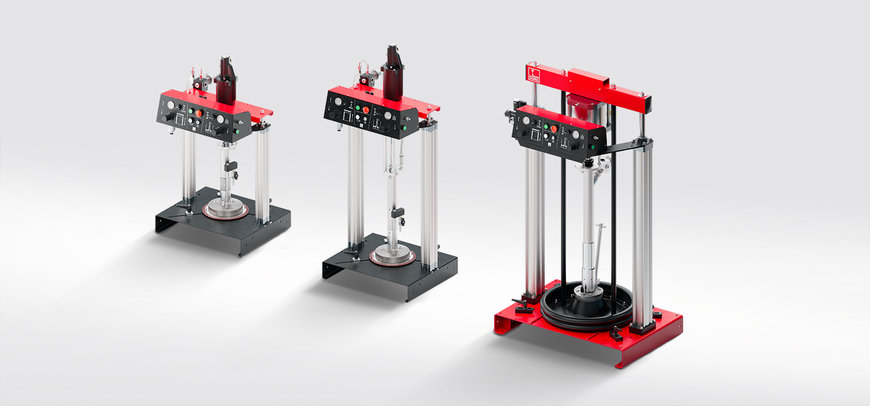

The lubricant pumps of the lubriLine from DOPAG for the three container sizes 30, 80 and 200 litres.

DOPAG has developed a new, modular series of drum pumps for feeding lubricants, adhesives and sealants. The powerful, double-acting piston pumps feed the material directly, efficiently and without air pockets from the original container. The series is characterised by its high level of user-friendliness and maximum flexibility in terms of configuration.

The series consists of the following two product lines:

- lubriLine (LL): Pumps for lubricants

- glueLine (GL): Pumps for adhesives and sealants

Individual configuration

The pumps are available in three versions for the typical container sizes 30, 80 and 200 litres. The basic design and operation remain the same in each case. The other components can be customised according to customer requirements. There is a choice between user-friendly 2-hand control with additional safety features and 1-hand block control. In addition, the pump can be equipped with different options such as filters, sealing fluid containers, deairing or homogenisation units and modules for external control or monitoring.

The container pumps of the glueLine, available for container sizes of 30, 80 and 200 litres, are suitable for processing adhesives and sealants.

Continuous material supply

The drum pumps are used in all dispensing applications in various industries, for example for greasing in the automotive industry or for bonding components in household appliance production. They are suitable as central material supply systems and as individual supply systems. To ensure a continuous supply of material when changing containers, the pumps are available as a tandem version. This ensures reliable and safe production at all times.

All benefits at a glance

- Individual configuration

- User-friendly and ergonomic 2-hand operation

- Material circulation and homogenisation prevent material separation

- Drum bottom detection to minimise material loss when changing containers

- Automatic follower plate deairing to make changing containers easier

- Available in various versions: stainless steel, wear-resistant, with ATEX certification

- Clean, oil-free high-performance drives

Click here for our new product video, all product information and technical data.

Video tutorials on initial setup and changing drums

DOPAG has created several video tutorials for the new drum pump series. The initial setup and drum change are explained for each of the different pump variants. At the same time, all additional features are presented in detail. This gives customers an initial overview of the operation and range of functions of the pumps. Further, they can use the videos as concrete instruction for the setup.

Click here for all videos.

www.dopag.com