MillOne: Boosting Operational Control Through Intelligent, Connected Production Systems

Voith’s digital platform enhances real-time visibility, decision-making and process stability across modern paper mills.

voith.com

Operational management in paper mills is under increasing pressure: Growing demands for transparency and responsiveness are coupled with scarce human resources and complex production environments. In response, systems such as Voith's MillOne form the digital heart of paper mills, creating a networked environment for stable, optimally coordinated production processes.

A key focus is on supporting operational control, i.e., the ability to quickly monitor production processes in real time and identify deviations at an early stage so that targeted action can be taken. MillOne achieves this through a central production center, production cockpit and alarm management system that provide operators with a quick overview of current production, for example, at the start of a shift.

Production Center: A quick orientation

“The Production Center is the central point of contact for operating personnel at the start of their shift,” explains Ulf Grohmann, Director of Product Management Autonomous Paper Mill at Voith Paper. A clearly structured dashboard provides all relevant information on current production and tasks – for example, the average machine speed or quality and efficiency values such as the fresh fiber content or steam consumption within a selectable period.

“By visually marking machine sections according to the action required, operators immediately get an overall impression of the current production,” says Grohmann. “This makes it a practical hand-off tool that greatly simplifies communication about shift progress and the current status of production.”

Along with initial insights into production data, the Production Center also provides information on operational processes. This includes both the production process with planned and unplanned downtimes and personnel planning with an integrated task overview that shows all activities at a glance. Reports and shift handoffs can also be accessed directly in the system. In addition, operators can quickly and easily view detailed information on each paper roll produced using a mouseover function.

Production Cockpit: Deeper insights for more targeted actions

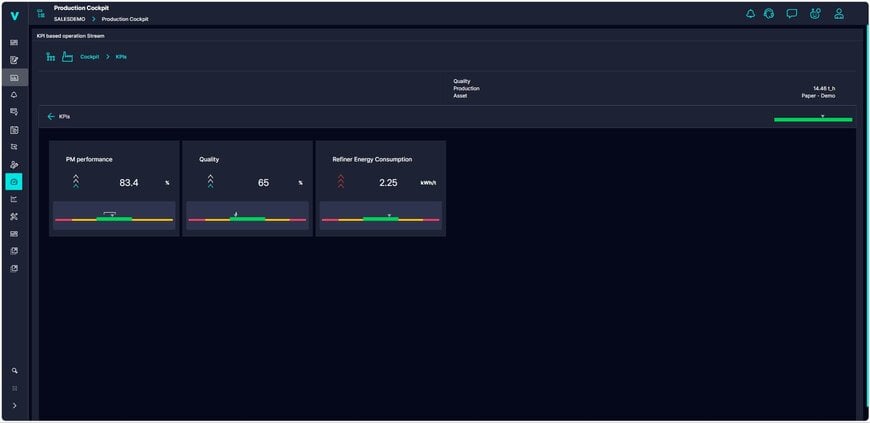

To gain more detailed insights into individual machine components and processes, staff can access the Production Cockpit. “Here, too, it was important to us to first provide a compact overview of the most important values, which the operator can define themselves,” explains Zsuzsanna Ozvary, Project Manager UX/UI Co-Development at Voith Paper. “A traffic light color system makes it immediately clear whether or not the respective key figures are within the desired range.” The limits can be set as classical static limits or be adaptive based on grades or more advanced algorithms (or rule/calculation-based). If necessary, users can dive deeper into the data.

“MillOne's Production Cockpit is much more than an attractively designed user interface,” adds Grohmann. “It combines visual clarity with powerful analysis functions that go beyond monitoring alone.”

For example, if the paper quality index falls below a defined threshold, the operator get a clear data driven recommendation from MillOne on the necessary changes. This enables even operators without in-depth analytical knowledge to interpret process values and identify trends. This action-oriented user guidance takes into account the increasing shortage of skilled workers and the associated need to control complex processes with less specialized personnel.

Structured alarm messages for faster responses

Another lever for clear operational control is focused alarm management. Lars Mallasch, Group Technical & Sustainability Director at Mondi, reports up to 3,000 alarms on a single machine in just one week. “To avoid flooding the operating personnel with too many messages, alarms are prioritized and clearly displayed in the MillOne interface,” says Grohmann. “This creates transparency in the event of a fault and enables fast, targeted responses.”

Alarms can be configured individually so that not only individual measured values but also complex process sequences can be monitored. This freedom enables the alarm structure to be adapted precisely to the conditions of the respective plants and to react quickly to changing requirements.

Conclusion

With MillOne, Voith demonstrates how digital production systems can bring more clarity to complex processes and support control in everyday production. The combination of central data access, intuitive user guidance, and integrated analysis and alarm functions creates a system that not only provides information but also actively supports decision-making. Especially in times of limited human resources and increasing demands on response times, MillOne proves to be a practical solution for controlling complex processes efficiently and reliably – and thus laying the foundation for future-proof paper production.

www.voith.com