www.industryemea.com

03

'23

Written on Modified on

Machine Vision and the End of Manual Visual Inspection

Computer or machine vision today has succeeded to a large extent in the attempt to mimic the human eye. Has machine vision replicated the ability of the human eye with all its complexities? Is this the end of the manual inspection? These are questions that cannot be answered with a simple ‘Yes’ or ‘No’ - By Milton D'Silva.

The eye is a complex organ of the human body. Photo by Colin Lloyd on Unsplash

Visual inspection with the naked eye is the oldest, simplest and most basic method of inspection when looking at a product or component for any defect or flaw. Of the 5 senses human beings are naturally equipped with, vision is the most important – the ability to see and differentiate between faces and objects. The eye is the most complex organ of the human body, next only to the brain. It has over 2 million parts! The eye looks at the surroundings and sees things as they are in terms of shapes, sizes and colours. All the information is interpreted through the light patterns and transmitted to the brain via the complex mechanism of the cornea, pupil, iris and the retina, which then transmits it to the brain through electrical signals, all in an instant!

The human eye can absorb a million simultaneous impressions and tell the difference between eight million different colours. All this is facilitated by the 126 million odd light-sensitive receptor cells present in the eye. Yet, it is dependent on light – one cannot see in the darkness with the naked eye; also it cannot see tiny or distant objects clearly. Some of these limitations are overcome by use of technical aids like night vision glasses based on thermal imaging, microscopes, telescopes, etc. Above all, human vision is a complex process which is still not fully comprehended. The complexity may be understood from the fact that despite much research and technological progress, there is no solution in sight to restore vision in all cases of human blindness. However there are sporadic examples where scientists have been successful in restoring partial vision, including one where the optic nerve was damaged.

Machine Vision

Machine vision is a technical process that uses cameras to capture images and other information from the surrounding environment. In other words machine vision is to machines what eyesight is to human beings – the ability to see. The acquired images and information is stored, processed and analysed by software and hardware devices, interpreted artificial intelligence, improved by machine learning and then used in various industrial applications like automatic inspection, process control, guiding robots to perform various tasks. Machine vision is often mixed up with computer vision, and though there are similarities, these are two different things. Computer vision is a field of artificial intelligence (AI) that enables computers and systems to derive meaningful information from digital images, videos and other visual inputs. So machine vision may be considered as a subset of computer vision.

While there are many different descriptions for machine vision, they all essentially say the same thing by using different terminology. According to the Automated Imaging Association (AIA), the world's largest machine vision trade group, machine vision encompasses all industrial and non-industrial applications in which a combination of hardware and software provide operational guidance to devices in the execution of their functions based on the capture and processing of images. Intel, the company that put silicon in Silicon Valley, describes machine vision as one of the founding technologies of industrial automation. Machine vision has helped improve product quality, speed production, and optimise manufacturing and logistics for decades. Now this proven technology is merging with artificial intelligence and leading the transition to Industry 4.0.

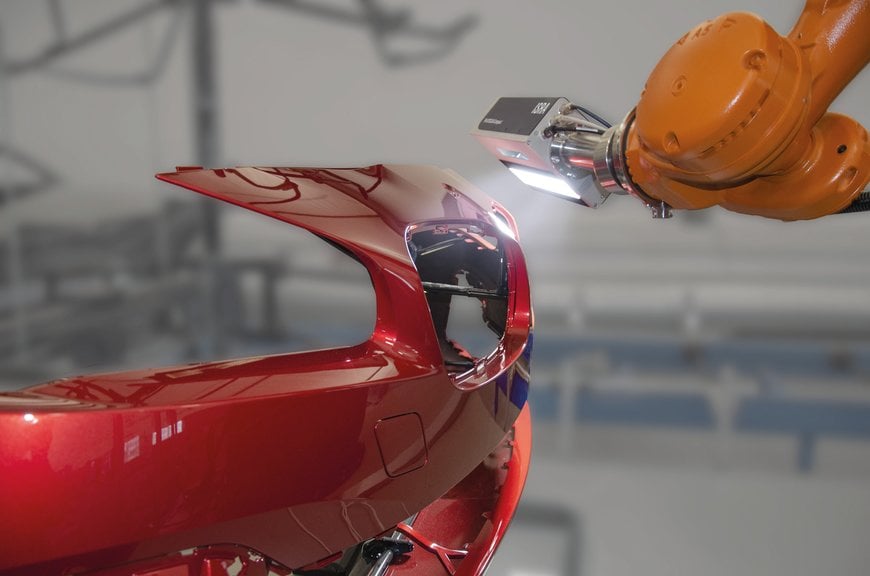

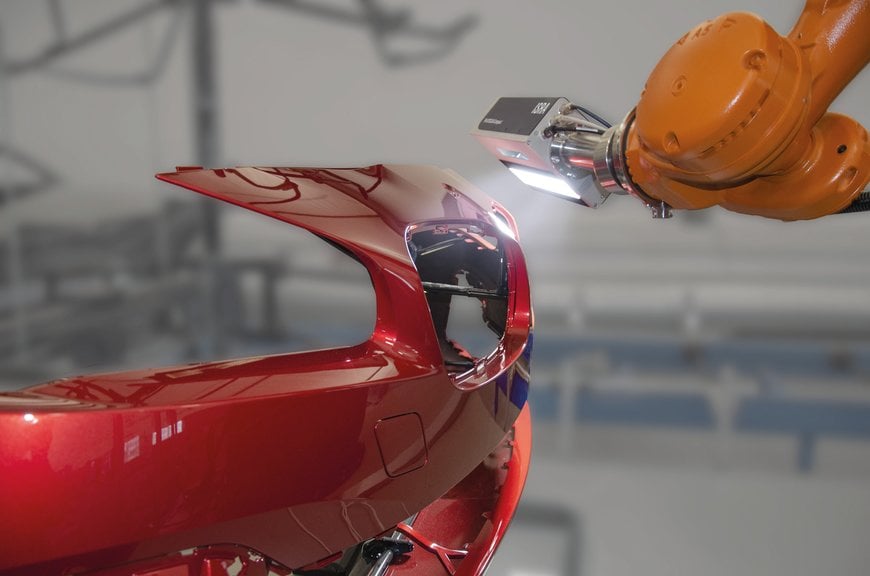

Bumper inspection with the ISRA Sensor PAINTSCAN. Picture: ISRA VISION

Manual Inspection Vs Machine Vision

Is machine vision superior to manual visual inspection? According to Dr Sandra Belmont, a leading ophthalmologist based in New York, though machine vision is unlikely to surpass the human eye for accuracy, it is capable of detecting and labeling objects with an accuracy that surpasses human inspection. An article published on the Belmont Eye Center website discusses at length how machine vision is outpacing human vision in accuracy and speed. Machine vision today is, with the use of AI and deep learning algorithms, mimicking the same neural pathways that the human eyes use when identifying images. As a result, machines are able to process data from multiple sources and apply pre-defined rules that enable them to achieve a far higher level of accuracy than humans. However, there are applications, especially in the pharma industry, that still rely on manual visual inspection, which in some cases is also a mandatory requirement, even if the volume of manually inspected batches is marginal.

A significant advantage of manual visual inspection is that the operators do not require any technical background but need to be trained to follow a standard operating procedure (SOP) for inspection during assembly. But even in places where manual inspection is still performed, the process has several disadvantages like diminishing accuracy due to fatigue and the slow process which is unsuitable for a high production environment. A more serious drawback is when there is a defect that is not outlined in the SOP and the operator is unable to notice it. So in the context of modern manufacturing and services industries, it is machine vision that is dominating the discourse, and has become an important part of the digital transformation journey.

Machine Vision Applications in Industry

Whatever manual visual inspection can do, machine vision can arguably do better. Or so it seems. The industry, on the other hand, has warmed up to the idea of machine vision technologies leading to better production efficiencies. According to P&S Intelligence, the global machine vision market size was valued at USD 14.4 billion in 2022 and is expected to increase to USD 27.86 billion in 2023 at a CAGR of 8.60% during the forecast period. Growing demand for quality inspection and automation in different industry verticals are the main growth drivers backed by surging R&D spends by leading players in the field. Increasing penetration of robots in the smart manufacturing ecosystem is another factor.

With rapid advances in technology, especially in deep learning algorithms, more and more applications are now possible with machine vision, apart from mere detection (absence/presence) of objects or sorting and pick and place. While bar code reading was one of the early applications, optical character recognition and verification are now optimised to near zero defects. Apart from this, the other common applications are: automated vision testing and measurement; colour verification; defect detection; part verification; pattern matching; traceability; and the more recent field of vision guided robots and AGVs/AMRs.

A 2017 research had put a figure of USD 50 bn to losses attributed to unplanned downtime caused by human error in manufacturing, which is more than in any other sector. Machine vision can play a significant role in eliminating a large chunk of these losses. Anna-Katrina Shedletsky, a former engineer at Apple and co-founder of Instrumental, believes that manufacturing's biggest problem is the 20 to 35 cents of every dollar spent in manufacturing that is wasted. While working at Apple, Shedletsky and Samuel Weiss, co-founder, Instrumental, experienced firsthand how manufacturing is inefficient and wasteful, and few tools were actually helping engineering and operations teams improve their processes.

In 2014, they left Apple to launch Instrumental, which has now become a leading manufacturing optimisation platform for electronics brands across the globe. “We’re proud to help some of the world’s most admired companies find failures faster and optimise their manufacturing process, while giving visibility into exactly what’s happening on the factory floor”, writes Shedletsky about what they are doing at Instrumental. According to her, computer vision has several benefits on the assembly line. With modern programs, automatic inspection of units using computer vision means that more mistakes are caught before units ramp into mass production. Part orientation, presence detection, part dimensions, and angles of part geometries can be checked according to specifications. If a computer vision program finds errors more quickly than human operators can, this translates into less time and resources wasted in the factory.

ABB autonomous mobile robot equipped with Sevensense’s navigation technology. Picture: ABB

Addressing the pain points

When ABB entered into a strategic partnership with Swiss-based start-up Sevensense in late 2021, the company was looking to enhance its new autonomous mobile robotics (AMR) offering with artificial intelligence and 3D vision mapping technology. Sevensense has developed a VSLAM navigation technology that uses advanced computer vision and AI algorithms to create a 3D map that is more accurate than 2D solutions, leading to superior navigation capabilities, and more cost-effective solutions than laser scanner-based navigation. ABB plans to integrate Sevensense’s soft- and hardware technology into ABB’s autonomous mobile robot (AMR) offering, with pilot customer projects now underway.

At the ProMAT2023 event recently, Sevensense introduced the Alphasense Autonomy Evaluation Kit, which accelerates the development and deployment of AGVs and AMRs while improving their performance and expanding their operational capabilities. “We observed that many AMR manufacturers considered Alphasense Autonomy as an option to incorporate 3D Visual Autonomy capabilities into their offering but integrating, testing, and validating the fit of this navigation technology in their own vehicles and their use cases still required more expertise and time than they were able to invest. The Alphasense Autonomy Evaluation Kit offers them an off-the-shelf option to easily and quickly test Alphasense Autonomy and take a generational technological leap forward,” says Gianluca Cesari, CBDO at Sevensense Robotics.

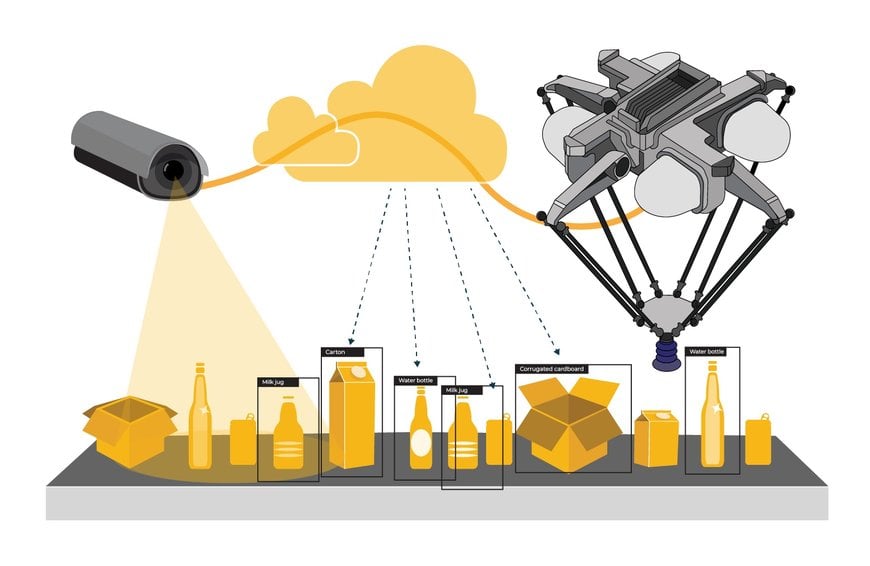

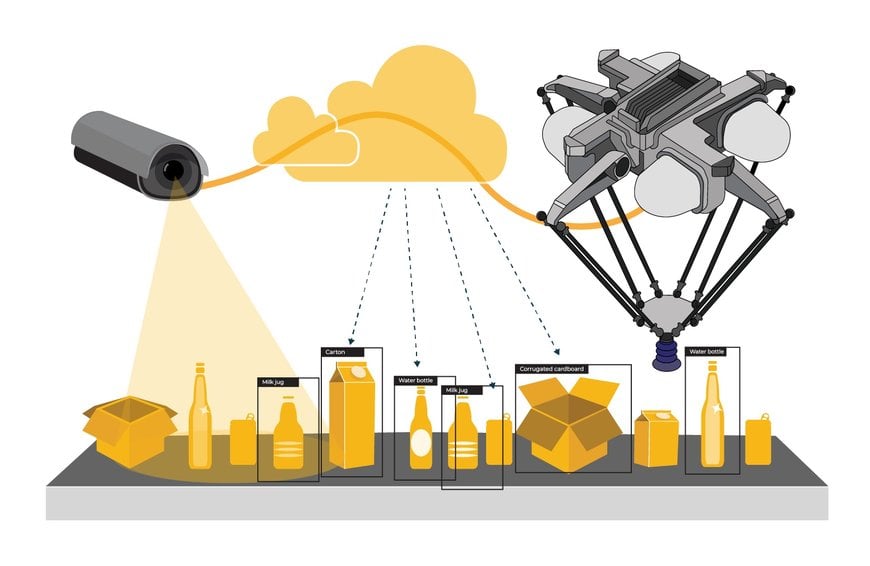

Similarly, US-based AMP Robotics is modernising the world’s recycling infrastructure by applying AI and automation to increase recycling rates and economically recover recyclables reclaimed as raw materials for the global supply chain. The AMP Cortex™ high-speed robotics system automates the identification and sorting of recyclables from mixed material streams. The AMP Neuron™ AI platform continuously trains itself by recognising different colors, textures, shapes, sizes, patterns, and even brand labels to identify materials and their recyclability. Neuron then guides robots to pick and place the material to be recycled. Next, the company’s AI platform, AMP Neuron™, uses computer vision to recognise patterns of specific recyclable materials within a complex waste stream of smashed, folded, and tattered objects – all combined together. Neuron distinguishes different plastic polymers, types of paper, metal containers, and multilayered packages to characterise what’s in the recycling stream and what needs to be sorted during different process stages. Neuron then guides robots to sort and recover what material to recycle or contamination to be removed.

The much talked about agile mobile robot Spot from Boston Dynamics, in its latest avatar is able to accomplish many tasks including collecting thousands of data points to drive predictive maintenance models, building comprehensive digital twins and keep workers away from dangerous or hazardous situations. BP, the British multinational oil and gas company was among the early companies to perform a proof of concept (POC) to verify that Spot could move reliably in an industrial environment. BP is now exploring the use of robots with LIDAR sensor payloads for generating 3D models, or digital twins that enable employees to virtually walk through and examine a facility from a safe remote location. In fact at the Vision 2022 event at Stuttgart in October 2022, Photoneo, an exhibitor, used Spot, equipped with MotionCam-3D – to welcome visitors to its booth and also performed a jig, moving around the crowds effortlessly, avoiding all obstacles in its path!

With advances in machine vision technologies now coming of age, development of new applications is restricted only by imagination.

AMP uses computer vision to recognise patterns of specific recyclable materials. Picture: AMP

Leading players & recent trends

While there is no definite record of the number of companies engaged in the machine vision field, major players in the field include Cognex Corporation, Basler AG, Omron Corporation, Keyence, National Instruments, Sony Corporation, Teledyne Technologies, Texas Instruments, Intel Corporation, ISRA Vision, Sick AG, FLIR Systems, Optotune AG, USS Vision, ViDi Systems SA, Bosch Rexroth and Euclid Labs, among others. A few of these companies are profiled in the following paragraphs.

OMRON Corporation

Omron's comprehensive machine vision hardware line includes industrial cameras, vision systems and smart and PC-based cameras that are scalable across software platforms. The portfolio offers compact form factors for tight spaces, high-speed imaging for fast-moving production lines, and high resolutions for detailed inspection. As the market's only total solution provider, OMRON combines its cameras with a powerful software platform that's fully integrated with the company’s controllers and robotic solutions and also works well with third-party devices. At the IPC Apex 2023 show in San Diego in January 2023, OMRON Automation Americas displayed the VT-Z600 and VT-S1040 automated optical inspection systems. These use advanced hardware and sophisticated image processing to deliver reliability and performance at production speeds in pre- and post-reflow inspection.

KEYENCE

KEYENCE is a leading supplier of sensors, measuring systems, laser markers, microscopes, and machine vision systems worldwide. At the forefront of factory automation, the company strives to develop innovative and reliable products to meet the needs of customers in every manufacturing industry. In addition to world-class products, KEYENCE offers a full range of services to further assist their customers. The technically trained direct sales force is able to solve tough applications and answer technical questions about KEYENCE products.

KEYENCE has recently launched a Vision Sensor with Built-in AI, IV3 series. Differing from conventional models, the IV3 Series Vision Sensor with Built-in AI automatically determines imaging conditions and detection conditions with its AI specifically designed for presence and difference checking. Installation and operation are simple: just determine the part to focus on and register a minimum of one OK and one NG image. No specialised knowledge or extensive time and effort for setup are required. The all-in-one design includes a lens and illumination, eliminating the need to select these devices and allowing for immediate finalization of detection results with no adverse effects from ambient light.

Boston Dynamics’ Spot equipped with Photoneo’s MotionCam-3D at Vision 2022. Picture: Messe Stuttgart

Cognex Corporation

Companies across the globe face complex manufacturing and operational challenges in the creation and fulfillment of quality products to their customers. Cognex machine vision and industrial barcode reading solutions help customers solve some of their most challenging and diverse application challenges. With domain knowledge of these problems, paired with innovative technology, Cognex can provide robust and repeatable solutions that address several challenges facing a broad range of industries; including guidance, identification, gauging, and inspection. Using these solutions, customers have increased process performance, improved product quality, and reduced costs.

One of the most hotly discussed topics in the manufacturing world today is Industry 4.0, or "The Industrial Internet of Things." Industry 4.0 refers to a set of emerging innovations in advanced automation, machine vision, Big Data, cloud computing and machine learning which will revolutionise manufacturing. Industry 4.0 demonstrates tremendous potential to bolster productivity, reduce waste, refine product quality, enhance manufacturing flexibility, decrease operating costs and deliver myriad other benefits to the factory floor.

Basler AG

Basler AG is a leading international manufacturer of high-quality imaging components for computer vision applications. In addition to classic area scan and line scan cameras, lenses, frame grabbers, light modules, and software, the company offers embedded vision modules and solutions, 3D products, as well as customized products and consulting services. Basler's products are used in a variety of markets and applications, including factory automation, medical, logistics, retail, and robotics. They are characterized by high reliability, an excellent price/performance ratio, and long-term availability. Founded in 1988, the Basler Group employs around 1000 people at its headquarters in Ahrensburg and other locations in Europe, Asia and North America. At Vision2022, the world's leading trade fair for machine vision held in Stuttgart (October 4-6, 2022) Basler showcased its comprehensive range of computer vision solutions. Key products included Basler's new ace 2 with 5GigE, new SWIR, thermal and 3D cameras, as well as roughly 200 new lighting components, and in software, pylon vTools image processing modules.

KEYENCE has recently launched IV3 series, a vision sensor with built-in AI. Picture: KEYENCE

SICK AG

SICK offers a wide range of vision products to help solve your camera-based applications. Applications range from part presence and positioning with vision sensors... to full 3D scanning and measurement using 3D cameras... to 2D code reading and OCR, allowing SICK to improve your processes at nearly every stage of the automated production line.

Recently, with the safeVisionary2, SICK launched the world’s first 3D Time-of-Flight (ToF) camera with safety certification performance level c in accordance with EN13849. In the process, SICK is setting a new milestone in safety technology and paving the way for efficient production and logistics processes. The 3D time-of-flight camera enables reliable three-dimensional environment perception as well as productivity-enhancing safety concepts, for instance for the automation of mobile robots and in human-robot collaboration.

Cognex can provide robust and repeatable solutions. Picture: Cognex Corporation

ISRA Vision

Since its foundation, ISRA's focus and strengths have been in the development of advanced embedded technologies and highly complex algorithms and bringing them to market as easy-to-use touch-and-automate and plug-and-automate systems. These machine systems, based on Industry 4.0-enabled concepts, provide an effective foundation for sustainable customer success based on the partnership from consulting to integration. From process automation and product optimisation to product efficiency and revenue maximisation, the innovative portfolio covers the entire production chain, deployed in renowned companies from around the world. For example, international premium car manufacturers and well-known market leaders from the information and communication industries rely on automation technology solutions from ISRA.

The company during the K 2022 trade fair in Düsseldorf in 2022 launched “Cloud Xperience” – a completely new online software platform for its SMASH inspection systems that combines the benefits of cloud computing with intelligent analytics tools for the first time. With its innovative approach to clustering and classifying defects based on artificial intelligence (AI), Cloud Xperience can help to ramp up production faster, ensure knowledge is accessible at all times, and control processes automatically.

Basler presented the ace 2 camera featuring 5GigE at Vision 2022. Picture: Basler AG

Conclusion

Computer or machine vision today has succeeded to a large extent in the attempt to mimic the human eye. Artificial intelligence is further helping scientists understand the complexities of brain and eye coordination, making use of multiple cameras to make sense of the dynamic industrial environment. So while the superiority of the human eye is unlikely to be surpassed, the ability to perform at extremely high speeds with a high level of success that machine vision has demonstrated is far beyond human capability.

On the flip side, even machine vision at the moment can only detect defects that it has been programmed for. Deep learning is still a work in progress and still far from reaching the goal where machines can fully master the tasks without human intervention.

References

1. https://www.eyesite.co.uk/news/humans-vs-animals-who-has-better-vision/

2. https://www.freethink.com/health/brain-implant-3#

3. https://belmonteyecenter.com/is-machine-vision-surpassing-the-human-eye-for-accuracy/

4. https://www.industryemea.com/market-overview/31325-machine-vision-in-industry

5. https://www.psmarketresearch.com/market-analysis/machine-vision-systems-and-components-market

6. https://instrumental.com/resources/improve-product-quality/machine-learning-is-reinventing-computer-vision-inspection-on-the-assembly-line/

7. https://fb.watch/jDR0e40ERD/

8. https://www.cognex.com/en-in/resources/white-papers-articles/introduction-to-machine-vision-17152

Visual inspection with the naked eye is the oldest, simplest and most basic method of inspection when looking at a product or component for any defect or flaw. Of the 5 senses human beings are naturally equipped with, vision is the most important – the ability to see and differentiate between faces and objects. The eye is the most complex organ of the human body, next only to the brain. It has over 2 million parts! The eye looks at the surroundings and sees things as they are in terms of shapes, sizes and colours. All the information is interpreted through the light patterns and transmitted to the brain via the complex mechanism of the cornea, pupil, iris and the retina, which then transmits it to the brain through electrical signals, all in an instant!

The human eye can absorb a million simultaneous impressions and tell the difference between eight million different colours. All this is facilitated by the 126 million odd light-sensitive receptor cells present in the eye. Yet, it is dependent on light – one cannot see in the darkness with the naked eye; also it cannot see tiny or distant objects clearly. Some of these limitations are overcome by use of technical aids like night vision glasses based on thermal imaging, microscopes, telescopes, etc. Above all, human vision is a complex process which is still not fully comprehended. The complexity may be understood from the fact that despite much research and technological progress, there is no solution in sight to restore vision in all cases of human blindness. However there are sporadic examples where scientists have been successful in restoring partial vision, including one where the optic nerve was damaged.

Machine Vision

Machine vision is a technical process that uses cameras to capture images and other information from the surrounding environment. In other words machine vision is to machines what eyesight is to human beings – the ability to see. The acquired images and information is stored, processed and analysed by software and hardware devices, interpreted artificial intelligence, improved by machine learning and then used in various industrial applications like automatic inspection, process control, guiding robots to perform various tasks. Machine vision is often mixed up with computer vision, and though there are similarities, these are two different things. Computer vision is a field of artificial intelligence (AI) that enables computers and systems to derive meaningful information from digital images, videos and other visual inputs. So machine vision may be considered as a subset of computer vision.

While there are many different descriptions for machine vision, they all essentially say the same thing by using different terminology. According to the Automated Imaging Association (AIA), the world's largest machine vision trade group, machine vision encompasses all industrial and non-industrial applications in which a combination of hardware and software provide operational guidance to devices in the execution of their functions based on the capture and processing of images. Intel, the company that put silicon in Silicon Valley, describes machine vision as one of the founding technologies of industrial automation. Machine vision has helped improve product quality, speed production, and optimise manufacturing and logistics for decades. Now this proven technology is merging with artificial intelligence and leading the transition to Industry 4.0.

Bumper inspection with the ISRA Sensor PAINTSCAN. Picture: ISRA VISION

Manual Inspection Vs Machine Vision

Is machine vision superior to manual visual inspection? According to Dr Sandra Belmont, a leading ophthalmologist based in New York, though machine vision is unlikely to surpass the human eye for accuracy, it is capable of detecting and labeling objects with an accuracy that surpasses human inspection. An article published on the Belmont Eye Center website discusses at length how machine vision is outpacing human vision in accuracy and speed. Machine vision today is, with the use of AI and deep learning algorithms, mimicking the same neural pathways that the human eyes use when identifying images. As a result, machines are able to process data from multiple sources and apply pre-defined rules that enable them to achieve a far higher level of accuracy than humans. However, there are applications, especially in the pharma industry, that still rely on manual visual inspection, which in some cases is also a mandatory requirement, even if the volume of manually inspected batches is marginal.

A significant advantage of manual visual inspection is that the operators do not require any technical background but need to be trained to follow a standard operating procedure (SOP) for inspection during assembly. But even in places where manual inspection is still performed, the process has several disadvantages like diminishing accuracy due to fatigue and the slow process which is unsuitable for a high production environment. A more serious drawback is when there is a defect that is not outlined in the SOP and the operator is unable to notice it. So in the context of modern manufacturing and services industries, it is machine vision that is dominating the discourse, and has become an important part of the digital transformation journey.

Machine Vision Applications in Industry

Whatever manual visual inspection can do, machine vision can arguably do better. Or so it seems. The industry, on the other hand, has warmed up to the idea of machine vision technologies leading to better production efficiencies. According to P&S Intelligence, the global machine vision market size was valued at USD 14.4 billion in 2022 and is expected to increase to USD 27.86 billion in 2023 at a CAGR of 8.60% during the forecast period. Growing demand for quality inspection and automation in different industry verticals are the main growth drivers backed by surging R&D spends by leading players in the field. Increasing penetration of robots in the smart manufacturing ecosystem is another factor.

With rapid advances in technology, especially in deep learning algorithms, more and more applications are now possible with machine vision, apart from mere detection (absence/presence) of objects or sorting and pick and place. While bar code reading was one of the early applications, optical character recognition and verification are now optimised to near zero defects. Apart from this, the other common applications are: automated vision testing and measurement; colour verification; defect detection; part verification; pattern matching; traceability; and the more recent field of vision guided robots and AGVs/AMRs.

A 2017 research had put a figure of USD 50 bn to losses attributed to unplanned downtime caused by human error in manufacturing, which is more than in any other sector. Machine vision can play a significant role in eliminating a large chunk of these losses. Anna-Katrina Shedletsky, a former engineer at Apple and co-founder of Instrumental, believes that manufacturing's biggest problem is the 20 to 35 cents of every dollar spent in manufacturing that is wasted. While working at Apple, Shedletsky and Samuel Weiss, co-founder, Instrumental, experienced firsthand how manufacturing is inefficient and wasteful, and few tools were actually helping engineering and operations teams improve their processes.

In 2014, they left Apple to launch Instrumental, which has now become a leading manufacturing optimisation platform for electronics brands across the globe. “We’re proud to help some of the world’s most admired companies find failures faster and optimise their manufacturing process, while giving visibility into exactly what’s happening on the factory floor”, writes Shedletsky about what they are doing at Instrumental. According to her, computer vision has several benefits on the assembly line. With modern programs, automatic inspection of units using computer vision means that more mistakes are caught before units ramp into mass production. Part orientation, presence detection, part dimensions, and angles of part geometries can be checked according to specifications. If a computer vision program finds errors more quickly than human operators can, this translates into less time and resources wasted in the factory.

ABB autonomous mobile robot equipped with Sevensense’s navigation technology. Picture: ABB

Addressing the pain points

When ABB entered into a strategic partnership with Swiss-based start-up Sevensense in late 2021, the company was looking to enhance its new autonomous mobile robotics (AMR) offering with artificial intelligence and 3D vision mapping technology. Sevensense has developed a VSLAM navigation technology that uses advanced computer vision and AI algorithms to create a 3D map that is more accurate than 2D solutions, leading to superior navigation capabilities, and more cost-effective solutions than laser scanner-based navigation. ABB plans to integrate Sevensense’s soft- and hardware technology into ABB’s autonomous mobile robot (AMR) offering, with pilot customer projects now underway.

At the ProMAT2023 event recently, Sevensense introduced the Alphasense Autonomy Evaluation Kit, which accelerates the development and deployment of AGVs and AMRs while improving their performance and expanding their operational capabilities. “We observed that many AMR manufacturers considered Alphasense Autonomy as an option to incorporate 3D Visual Autonomy capabilities into their offering but integrating, testing, and validating the fit of this navigation technology in their own vehicles and their use cases still required more expertise and time than they were able to invest. The Alphasense Autonomy Evaluation Kit offers them an off-the-shelf option to easily and quickly test Alphasense Autonomy and take a generational technological leap forward,” says Gianluca Cesari, CBDO at Sevensense Robotics.

Similarly, US-based AMP Robotics is modernising the world’s recycling infrastructure by applying AI and automation to increase recycling rates and economically recover recyclables reclaimed as raw materials for the global supply chain. The AMP Cortex™ high-speed robotics system automates the identification and sorting of recyclables from mixed material streams. The AMP Neuron™ AI platform continuously trains itself by recognising different colors, textures, shapes, sizes, patterns, and even brand labels to identify materials and their recyclability. Neuron then guides robots to pick and place the material to be recycled. Next, the company’s AI platform, AMP Neuron™, uses computer vision to recognise patterns of specific recyclable materials within a complex waste stream of smashed, folded, and tattered objects – all combined together. Neuron distinguishes different plastic polymers, types of paper, metal containers, and multilayered packages to characterise what’s in the recycling stream and what needs to be sorted during different process stages. Neuron then guides robots to sort and recover what material to recycle or contamination to be removed.

The much talked about agile mobile robot Spot from Boston Dynamics, in its latest avatar is able to accomplish many tasks including collecting thousands of data points to drive predictive maintenance models, building comprehensive digital twins and keep workers away from dangerous or hazardous situations. BP, the British multinational oil and gas company was among the early companies to perform a proof of concept (POC) to verify that Spot could move reliably in an industrial environment. BP is now exploring the use of robots with LIDAR sensor payloads for generating 3D models, or digital twins that enable employees to virtually walk through and examine a facility from a safe remote location. In fact at the Vision 2022 event at Stuttgart in October 2022, Photoneo, an exhibitor, used Spot, equipped with MotionCam-3D – to welcome visitors to its booth and also performed a jig, moving around the crowds effortlessly, avoiding all obstacles in its path!

With advances in machine vision technologies now coming of age, development of new applications is restricted only by imagination.

AMP uses computer vision to recognise patterns of specific recyclable materials. Picture: AMP

Leading players & recent trends

While there is no definite record of the number of companies engaged in the machine vision field, major players in the field include Cognex Corporation, Basler AG, Omron Corporation, Keyence, National Instruments, Sony Corporation, Teledyne Technologies, Texas Instruments, Intel Corporation, ISRA Vision, Sick AG, FLIR Systems, Optotune AG, USS Vision, ViDi Systems SA, Bosch Rexroth and Euclid Labs, among others. A few of these companies are profiled in the following paragraphs.

OMRON Corporation

Omron's comprehensive machine vision hardware line includes industrial cameras, vision systems and smart and PC-based cameras that are scalable across software platforms. The portfolio offers compact form factors for tight spaces, high-speed imaging for fast-moving production lines, and high resolutions for detailed inspection. As the market's only total solution provider, OMRON combines its cameras with a powerful software platform that's fully integrated with the company’s controllers and robotic solutions and also works well with third-party devices. At the IPC Apex 2023 show in San Diego in January 2023, OMRON Automation Americas displayed the VT-Z600 and VT-S1040 automated optical inspection systems. These use advanced hardware and sophisticated image processing to deliver reliability and performance at production speeds in pre- and post-reflow inspection.

KEYENCE

KEYENCE is a leading supplier of sensors, measuring systems, laser markers, microscopes, and machine vision systems worldwide. At the forefront of factory automation, the company strives to develop innovative and reliable products to meet the needs of customers in every manufacturing industry. In addition to world-class products, KEYENCE offers a full range of services to further assist their customers. The technically trained direct sales force is able to solve tough applications and answer technical questions about KEYENCE products.

KEYENCE has recently launched a Vision Sensor with Built-in AI, IV3 series. Differing from conventional models, the IV3 Series Vision Sensor with Built-in AI automatically determines imaging conditions and detection conditions with its AI specifically designed for presence and difference checking. Installation and operation are simple: just determine the part to focus on and register a minimum of one OK and one NG image. No specialised knowledge or extensive time and effort for setup are required. The all-in-one design includes a lens and illumination, eliminating the need to select these devices and allowing for immediate finalization of detection results with no adverse effects from ambient light.

Boston Dynamics’ Spot equipped with Photoneo’s MotionCam-3D at Vision 2022. Picture: Messe Stuttgart

Cognex Corporation

Companies across the globe face complex manufacturing and operational challenges in the creation and fulfillment of quality products to their customers. Cognex machine vision and industrial barcode reading solutions help customers solve some of their most challenging and diverse application challenges. With domain knowledge of these problems, paired with innovative technology, Cognex can provide robust and repeatable solutions that address several challenges facing a broad range of industries; including guidance, identification, gauging, and inspection. Using these solutions, customers have increased process performance, improved product quality, and reduced costs.

One of the most hotly discussed topics in the manufacturing world today is Industry 4.0, or "The Industrial Internet of Things." Industry 4.0 refers to a set of emerging innovations in advanced automation, machine vision, Big Data, cloud computing and machine learning which will revolutionise manufacturing. Industry 4.0 demonstrates tremendous potential to bolster productivity, reduce waste, refine product quality, enhance manufacturing flexibility, decrease operating costs and deliver myriad other benefits to the factory floor.

Basler AG

Basler AG is a leading international manufacturer of high-quality imaging components for computer vision applications. In addition to classic area scan and line scan cameras, lenses, frame grabbers, light modules, and software, the company offers embedded vision modules and solutions, 3D products, as well as customized products and consulting services. Basler's products are used in a variety of markets and applications, including factory automation, medical, logistics, retail, and robotics. They are characterized by high reliability, an excellent price/performance ratio, and long-term availability. Founded in 1988, the Basler Group employs around 1000 people at its headquarters in Ahrensburg and other locations in Europe, Asia and North America. At Vision2022, the world's leading trade fair for machine vision held in Stuttgart (October 4-6, 2022) Basler showcased its comprehensive range of computer vision solutions. Key products included Basler's new ace 2 with 5GigE, new SWIR, thermal and 3D cameras, as well as roughly 200 new lighting components, and in software, pylon vTools image processing modules.

KEYENCE has recently launched IV3 series, a vision sensor with built-in AI. Picture: KEYENCE

SICK AG

SICK offers a wide range of vision products to help solve your camera-based applications. Applications range from part presence and positioning with vision sensors... to full 3D scanning and measurement using 3D cameras... to 2D code reading and OCR, allowing SICK to improve your processes at nearly every stage of the automated production line.

Recently, with the safeVisionary2, SICK launched the world’s first 3D Time-of-Flight (ToF) camera with safety certification performance level c in accordance with EN13849. In the process, SICK is setting a new milestone in safety technology and paving the way for efficient production and logistics processes. The 3D time-of-flight camera enables reliable three-dimensional environment perception as well as productivity-enhancing safety concepts, for instance for the automation of mobile robots and in human-robot collaboration.

Cognex can provide robust and repeatable solutions. Picture: Cognex Corporation

ISRA Vision

Since its foundation, ISRA's focus and strengths have been in the development of advanced embedded technologies and highly complex algorithms and bringing them to market as easy-to-use touch-and-automate and plug-and-automate systems. These machine systems, based on Industry 4.0-enabled concepts, provide an effective foundation for sustainable customer success based on the partnership from consulting to integration. From process automation and product optimisation to product efficiency and revenue maximisation, the innovative portfolio covers the entire production chain, deployed in renowned companies from around the world. For example, international premium car manufacturers and well-known market leaders from the information and communication industries rely on automation technology solutions from ISRA.

The company during the K 2022 trade fair in Düsseldorf in 2022 launched “Cloud Xperience” – a completely new online software platform for its SMASH inspection systems that combines the benefits of cloud computing with intelligent analytics tools for the first time. With its innovative approach to clustering and classifying defects based on artificial intelligence (AI), Cloud Xperience can help to ramp up production faster, ensure knowledge is accessible at all times, and control processes automatically.

Basler presented the ace 2 camera featuring 5GigE at Vision 2022. Picture: Basler AG

Conclusion

Computer or machine vision today has succeeded to a large extent in the attempt to mimic the human eye. Artificial intelligence is further helping scientists understand the complexities of brain and eye coordination, making use of multiple cameras to make sense of the dynamic industrial environment. So while the superiority of the human eye is unlikely to be surpassed, the ability to perform at extremely high speeds with a high level of success that machine vision has demonstrated is far beyond human capability.

On the flip side, even machine vision at the moment can only detect defects that it has been programmed for. Deep learning is still a work in progress and still far from reaching the goal where machines can fully master the tasks without human intervention.

References

1. https://www.eyesite.co.uk/news/humans-vs-animals-who-has-better-vision/

2. https://www.freethink.com/health/brain-implant-3#

3. https://belmonteyecenter.com/is-machine-vision-surpassing-the-human-eye-for-accuracy/

4. https://www.industryemea.com/market-overview/31325-machine-vision-in-industry

5. https://www.psmarketresearch.com/market-analysis/machine-vision-systems-and-components-market

6. https://instrumental.com/resources/improve-product-quality/machine-learning-is-reinventing-computer-vision-inspection-on-the-assembly-line/

7. https://fb.watch/jDR0e40ERD/

8. https://www.cognex.com/en-in/resources/white-papers-articles/introduction-to-machine-vision-17152