The Green Hydrogen Path to Net Zero

Green hydrogen is the vital link in the quest for decarbonisation for a better tomorrow, writes Milton D’Silva.

The growing importance of hydrogen as a clean source of energy. Image by Akitada31/Roman from Pixabay

From the 21st session of the Conference of Parties (COP21) at Paris in 2015 to the COP28 meet at the UAE in 2023, the world has experienced dramatic climate events that proved the sceptics of global warming wrong. COP21 at Paris reached a landmark agreement to combat climate change by keeping a global temperature rise this century well below 2 degrees Celsius above pre-industrial levels and going further, striving to restrict it to 1.5 degrees Celsius by 2050. It was decided that the most important step to achieve this would be to reduce the world’s dependence on fossil fuels that are major contributors to Greenhouse gases (GHGs), which in turn lead to global warming.

While the irony of holding the recent COP28 meet in the UAE – one of the world’s top 10 producers of oil – was not lost on anyone, the real surprise was the resolution adopted at the summit whereby for the first time, countries agreed on the need to transition away from fossil fuels in energy systems by 2050. While critics maintain that the caveat of doing so ‘in a just, orderly and equitable manner’ provides many loopholes, the achievement is significant in many ways, as the year 2023 has turned out to be the hottest year in recorded history and one that witnessed numerous extreme weather events.

Also at COP28, the participants agreed to work collaboratively and expeditiously to pursue the following objectives:

- Work together to triple the world’s installed renewable energy generation capacity to at least 11,000 GW by 2030.

- Collectively double the global average annual rate of energy efficiency improvements from around 2% to over 4% every year until 2030.

- Commit to put the principle of energy efficiency as the "first fuel” at the core of policymaking, planning, and major investment decisions.

Amidst this scenario, the role of hydrogen as a clean source of energy assumes greater urgency as the world is now quite serious about pursuing the Net Zero Goal by 2050, and more importantly, reach the halfway mark by 2030.

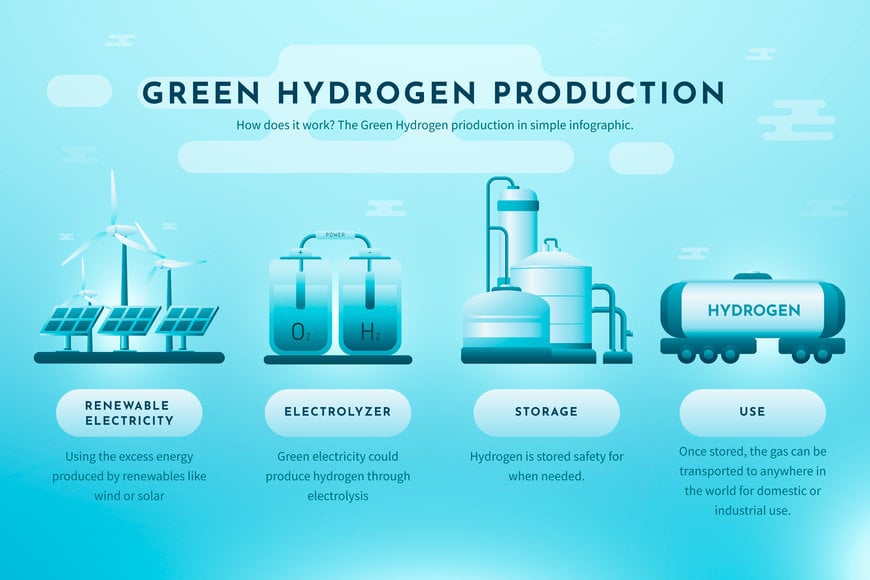

An infographic showing Green hydrogen production process. Image by Freepik

What is hydrogen?

Anyone who has studied chemistry in school is familiar with the basics of hydrogen – a chemical element with symbol H and atomic number 1, classified as a nonmetal, and a gas at room temperature; and also that it is colourless, odourless, tasteless, non-toxic, and highly combustible. The high school chemistry syllabus mentions British scientist Henry Cavendish as the person who first identified hydrogen as a distinct element in 1776, through his experiment of dipping zinc metal in hydrochloric acid causing the release of hydrogen gas. Like many other discoveries, this was however not the first attempt and it is widely acknowledged that it was Phillip von Hohenheim – a Swiss alchemist – who had, in the early 16th century, first produced hydrogen artificially in gas form without being aware of its significance. Later, in 1671, chemistry pioneer Robert Boyle through his experiments had proved the flammable nature of hydrogen, but since it was Cavendish who actually documented it, he is widely credited with the discovery.

Robet Boyle is of course better known for Boyle’s Law after his discovery that the volume of a gas decreases with increasing pressure and vice versa. Cavendish not only discovered hydrogen but also found out with further experiments that water is made of hydrogen and oxygen (H2O). Later, several scientists working independently or in collaboration built upon what Cavendish had demonstrated. In 1800, two British scientists, William Nicholson and Sir Anthony Carlisle, discovered electrolysis – the process of producing hydrogen and oxygen gases by applying electric current to water. The other important breakthrough was the reverse – combining hydrogen and oxygen gases to produce water and electric current, which was discovered by Swiss chemist Christian Friedrich Schoenbein and called the fuel cell effect.

The discovery of hydrogen and its composition as well as properties and the methods to produce it soon led to more experiments. One thing was obvious though – that hydrogen does not exist independently in nature but can be produced by using energy, and hence came to be known as an energy carrier, i.e., it can be used to store, move, and deliver energy produced from other sources – either fossil fuels or renewables. The fuel cell effect also demonstrated that as a fuel hydrogen burns clean without generating any contaminants or byproducts except water and electricity. Hydrogen can also be used as a fuel to power conventional heat engines, much like CNG. In fact the rockets used in space programmes are powered by liquid hydrogen. Though most of the hydrogen produced in the world today is used by refineries or as feedstock in the chemicals industry, it can also be used in many different ways – to generate electricity, power vehicles and in cold weather conditions, for heating homes and commercial buildings. It is the latter that has the potential to be the game-changer in reducing carbon emissions in quest of achieving net zero. However, for that to happen, much depends on how hydrogen is produced.

The many types of hydrogen

Hydrogen is available abundantly in nature – it forms almost 75% of the mass of the universe, present as it is in molecular form in all living organisms, but very rarely as a gas. Unlike methane or other hydrocarbons that are basically fossil fuels and generate contaminants during combustion, hydrogen burns clean without any residue. Alternatively, hydrogen can be fed to fuel cells to generate electricity for mobile or stationary applications, the only byproducts being heat and water. Fuel cells also have several advantages over storage batteries and are a better alternative to battery-based electric vehicles, especially heavy commercial vehicles and other applications.

Thanks to its potential to produce energy without emitting any greenhouse gases, hydrogen is considered a clean fuel. It has several advantages, and also some disadvantages. However, hydrogen as a clean fuel is only half the story as far as its importance in achieving the Net Zero goal. Since hydrogen production needs other energy sources, it really depends on what is the source of energy used for hydrogen production and thereby hangs a tale. The overall environmental impact of hydrogen depends heavily on how it is produced.

Based on the way it is produced, the colourless hydrogen has been given colour codes to grade it on the emissions scale of the production process. But first the production processes. There are three primary methods of hydrogen production:

- Steam Methane Reforming (SMR): This method uses natural gas as a feedstock, and it is currently the most common way of producing hydrogen, and in fact produces the most hydrogen today – almost 99%.

- Electrolysis: This process involves using electricity to split water (H2O) into hydrogen (H2) and oxygen (O2), and one that is potentially the most significant from the Net Zero perspective.

- Thermochemical Processes and Other Technologies: There are alternative methods such as high-temperature electrolysis and thermochemical water splitting that can be used for hydrogen production. These methods may offer certain advantages, but are in the early stages of development.

The SoHyCal Green hydrogen plant of H2B2 Electrolysis Technologies in North America. Photo: H2B2

In general, the first two, i.e., SMR and Electrolysis, are the most widely used processes with some variations in the actual method used, and the third is still a work in progress.

Coming to the colour codes for classification, the three most common types of hydrogen are Grey, Blue and Green.

Grey: The most common form of hydrogen production today, Grey hydrogen is created from natural gas, or methane, using the SMR method. During this process, carbon dioxide (CO2) is produced as a byproduct. The term ‘grey’ is used because the carbon emissions associated with this production method are not captured or mitigated, and hence there are greenhouse gases released in the atmosphere, resulting in environmental concerns. Grey hydrogen is the cheapest form of hydrogen today. Apart from the hydrogen produced by SMR method, that produced by electrolysis with electricity generated by fossil fuels is also classified as Grey.

Blue: An improvement over the Grey type, Blue hydrogen is produced with the same SMR method using natural gas, similar to grey hydrogen, but there is an additional step to reduce carbon emissions. The additional step is the process of carbon capture and storage (CCS), a technology used to capture the CO2 emissions generated during the process. The CO2 thus captured is transported and stored in geological formations deep underground. Apart from the cost of CCS which makes Blue hydrogen expensive compared to Grey, the technology itself is not very effective. Experts point out that few projects, if any, reach the goal of 90% capture of CO2, and in reality many just reduce emissions by a mere 10-11%. Hydrogen produced by electrolysis with electricity generated by fossil fuels but where the power plant uses CCS technology is also classified as Blue.

Green: Green hydrogen is produced through the electrolysis process using electricity. What sets green hydrogen apart is that the electricity used in the process comes from renewable energy sources, such as wind, solar, or hydropower, and not generated with fossil fuels. Since the electricity is generated without emitting greenhouse gases, the overall carbon footprint of Green hydrogen is minimal, making it an environmentally friendly option. But this also makes Green hydrogen more expensive than Grey and Blue as renewable energy in general costs more; but if the process uses surplus renewable energy from wind and solar power, then the equation changes, and so do the cost implications.

Besides these three main types of hydrogen colour coded Grey, Blue and Green, there are a few more colours in the hydrogen spectrum based on the source of energy used in producing it. Their description in brief is as follows:

Black and Brown: Perhaps the most harmful hydrogen from the environment perspective, Black and Brown hydrogen is created using traditional black coal or lignite (brown) coal through the process of gasification that converts carbon-rich materials into hydrogen and carbon dioxide. Since the emissions are released into the air, this is the exact opposite of Green hydrogen.

Pink: Hydrogen when produced through electrolysis by using nuclear energy is called pink hydrogen, sometimes also called purple or red hydrogen. Heat from nuclear reactors is also sometimes used in the SMR method.

Turquoise: A recent addition to the hydrogen spectrum, Turquoise hydrogen is produced by a process called ‘methane pyrolysis’, with solid carbon as a byproduct. It is still evolving and has the potential to become low-emissions hydrogen if powered by renewable energy and the carbon stored safely.

Yellow: It is like Green hydrogen but produced by using the electrolysis method exclusively powered by solar energy.

White: This is the hydrogen that is formed naturally and found in underground deposits of geological hydrogen. It can be extracted by fracking, but at the moment not under commercial considerations.

The Iberdrola Group’s plant producing Green hydrogen for industrial use in Spain. Photo: Iberdrola Group

The future is Green

At one time, hydrogen, besides its use in refineries and chemical industry, was seen as a clean fuel for automobiles. In fact the term Hydrogen Economy was coined by John Bockris, a chemistry professor, and first used publicly in the early 1970s, describing hydrogen as an economical and environmentally friendly substitute for fossil fuels to power automobiles. That was the period of growing realisation of the finite nature of fossil fuel supplies as well as rising awareness of the harmful effects of pollution. The periodic oil crisis, the most notorious being the 1973 oil shock that increased crude oil prices by 400%, lent further impetus to the growing interest in hydrogen. The progress however was slow and most predictions about fuel cell vehicles failed to materialise and battery electric vehicles became popular during recent years. Today, hydrogen is seen as a solution not just for automotive use, but for all industries that need energy which comes from fossil fuels. Currently, almost all hydrogen produced commercially is of the Grey variety, which is cheap since there is no cost to offset carbon emissions. Green hydrogen on the other hand, produced using only renewable energy, is 3-4 times more expensive. But despite this Green hydrogen is seen as the future because of the Net Zero mandate where Grey hydrogen offers no solution.

It is not the Net Zero mandate alone that is accelerating the clean hydrogen initiative. Other developments, like the Ukraine-Russia conflict that has disrupted the European natural gas supply chain and the volatile situation in the Middle East, are issues that lend further urgency. Some of the efforts and initiatives include:

- The Hydrogen Council, a global CEO-led initiative brings together leading companies with a united vision. Launched at the World Economic Forum in Davos in January 2017, it was the first initiative of its kind in the world. Composed initially of 13 leaders from the energy, transportation and manufacturing sectors, in six years, the Council now includes close to 150 multinational companies representing the entire hydrogen value chain. All major oil companies are among the members of the Hydrogen Council.

- The Hydrogen Production and Infrastructure Projects Database compiled by the International Energy Agency (IEA), as part of efforts to track advances in low-emissions hydrogen technology, covers all projects commissioned worldwide since 2000 to produce hydrogen for energy or climate change-mitigation purposes. The database has records of all hydrogen production as well as infrastructure projects.

- The Accelerating Clean Hydrogen initiative has over 200 members from 60 organisations, including public and private stakeholders dedicated to accelerating the development of the clean hydrogen economy.

In her Foreword to Deloitte’s 2023 Global Green Hydrogen Outlook, Jennifer Steinmann, Global Sustainability & Climate Practice Leader, Deloitte Global, observes: While the greatest energy mix switch will be toward electricity from renewable sources, 15% to 30% of future energy needs is likely to be satisfied by hydrogen, a function of sectors that may not be able to electrify easily (hard-to-abate sectors) and of the creation of additional demand from new products and services – for example, green steel. In the context of the timeframe for the world to achieve Net-Zero, hydrogen, and in particular green hydrogen, gains significant currency. An earlier Deloitte report predicts that clean hydrogen as a reliable, sustainable energy source is gathering strength and is expected to top the value of the liquid natural gas trade by 2030. It is set to grow further to US$1.4 trillion per year by 2050, with the bulk of the growth driven by Green hydrogen.

China’s first major photovoltaic Green hydrogen pilot project. Photo: Sinopec

Scaling up production

The investments required for scaling up production of Green hydrogen are huge. This is something not possible without the proactive role of government policies and incentives in promoting Green hydrogen production. Thanks to the global initiatives to combat climate change, there is now near universal support for decarbonisation of energy in a bid to move away from fossil fuels and Green hydrogen is an important component of this movement.

The US, for example, has drawn a national Green hydrogen road map and recently published a policy report on its hydrogen strategy. The Bipartisan Infrastructure Law of 2021 has provision of USD 9.5 bn for clean hydrogen. This is supplemented by the provisions of the Inflation Reduction Act, 2022 that provides additional policies and incentives for hydrogen including a production tax credit that has further boosted a US market for clean hydrogen. According to a recent news release, H2B2 Electrolysis Technologies, Inc., a global vertically integrated provider of green hydrogen energy solutions across the hydrogen value chain, has unveiled SoHyCal – the largest operational Green hydrogen production plant powered entirely by renewable energy in North America to date. This project, from both a technical and commercial point of view, consists of the construction, financing and operation of a 100% renewable hydrogen production plant with PEM technology.

The Australian government is investing more than A$1.3 billion to speed up the development of its hydrogen industry. This includes A$464 million to develop clean hydrogen industrial hubs in regional Australia. It has also launched the A$150 million Australian Clean Hydrogen Trade Program. The program will support Australian-based hydrogen supply chain projects that secure overseas public or private sector investment. The first round of the program is focussed on the export of clean hydrogen to Japan under the Japan-Australia Partnership on Decarbonisation through Technology. Australia’s largest energy infrastructure project, the Western Green Energy Hub is an ultra-scale renewable energy project that will generate around 50GW of electricity via upstream combined solar and wind. This will enable more than 3.5 million tonnes of green hydrogen per year to be produced, for use in power generation, shipping fuel, minerals processing, and manufacturing.

In Europe, the Spanish government has developed the country’s hydrogen roadmap with a plan to contribute to achieving climate neutrality and a 100% renewable electricity system with objectives for 2030 and a vision for 2050 to ensure that renewable hydrogen contributes to the country’s climate neutrality by 2050. Spanish companies are already beginning to invest in renewable hydrogen projects. Enagás, the Spanish energy company and transmission system operator that owns and operates the nation’s gas grid, is planning the largest hydrogen plant in Spain. This installation would involve an investment of USD 309 million. The project consists of a 32 MW electrolyzer, powered by a 150 MW photovoltaic plant. There will also be a warehouse for daily production of 12 tonnes of green hydrogen and other associated infrastructure. Similarly, the Iberdrola Group – a global energy leader – has commissioned the largest plant producing Green hydrogen for industrial use in Spain that consists of a 100 MW photovoltaic solar plant, a lithium-ion battery system with a storage capacity of 20 MWh and one of the largest electrolytic hydrogen production systems in the world (20 MW).

In early 2022, China officially revealed its first-ever long-term plan for hydrogen, covering the period of 2021-2035 as part of its 14 Five-Year Plan. The plan laid out a phased approach to developing a domestic hydrogen industry and mastering technologies and manufacturing capabilities, while pointing to the country’s carbon peaking and neutrality commitments as an overarching driver. China is at present the world’s largest producer of hydrogen with an estimated production of 33 million tonnes, mostly of Grey variety for use as feedstock in refineries and chemical facilities. By 2030, China expects to install 100 GW capacity of electrolyzers to produce green hydrogen. Sinopec, China’s leading hydrogen producer has already put in operation the world’s largest green hydrogen facility, the 260MW Kuqa project in Xinjiang, which has started production, with an initial output of 10,000 tonnes a year.

In the meanwhile in the Kingdom of Saudi Arabia, the Neom Green Hydrogen Company announced the financial closure of a total investment value of USD 8.4 billion in the world’s largest carbon-free green hydrogen plant, to build the world’s largest green hydrogen plant to produce green ammonia at scale in 2026. Neom is a region in the north west of the Kingdom of Saudi Arabia and is built as a futuristic cityscape with a total planned area of 26,500 km2. The city's plans include multiple regions, including a floating industrial complex, global trade hub, tourist resorts and a linear city powered by renewable energy sources. Saudi Arabia has put in place a National Hydrogen Strategy, targeting 4 million tonnes per year of clean hydrogen, and aims to make the country a leader in its production and export. For long a dominant player in the oil market, the country in recent years has undergone a significant energy transition, recognising the need to shift towards renewable energy and reduce its carbon footprint.

The Indian government approved in 2023 the National Green Hydrogen Mission with the aim to develop green hydrogen production capacity of at least 5 MMT per annum along with a renewable energy capacity addition of around 125 GW in India resulting in abatement of nearly 50 MMT of annual greenhouse gas emissions by 2030. With the stated mission to make India the Global Hub for production, usage and export of Green Hydrogen and its derivatives, the country aims to become self reliant through clean energy and serve as an inspiration for the global Clean Energy Transition. The mission will lead to significant decarbonisation of the economy, reduced dependence on fossil fuel imports, and enable India to assume technology and market leadership in Green hydrogen. In September 2023, Tata Steel and ACME Group announced collaboration to launch the country’s largest green hydrogen project at Gopalpur Industrial Park in Odisha State. The Rs 27,000 crore (USD 3.24 bn) initiative aims to establish a green ammonia facility, which will rely on Green hydrogen, produced through the electrolysis process utilising renewable energy sources.

The examples above of 6 different countries and their Green hydrogen plans are representative of what is happening in major economies of the world. Canada and Chile in the Americas, Germany and The Netherlands in Europe, Kazakhstan in Central Asia, Oman and UAE in the Gulf region, and Mauritania and South Africa on the African continent – there are dozens of other countries with ambitious plans for Green hydrogen and the list is growing.

The Neom Green Hydrogen Company has recently announced the world’s largest carbon-free green hydrogen plant in Saudi Arabia.

Conclusion

As the world comes to realise there is no alternative to cleaning up the energy sector by decarbonising it, hydrogen will form an important component of the clean energy basket.

As the curtains came down on the COP28 meet at UAE, the participants acknowledged that renewable and low-carbon hydrogen and hydrogen derivatives will play an essential role in meeting global energy needs and decarbonising industries as part of a people-centred energy transition to net zero that leaves no-one behind. It is not going to be a smooth transition though, as concerns remain – on the investments front, on the safety front as well as on the infrastructure front. It is a challenge the world must accept in the absence of better alternatives. Hydrogen alone cannot deal with the climate crisis but it is going to be an essential part of the basket of solutions to tackle the biggest challenge humanity faces today. With economies of scale as well as technology breakthroughs reducing the cost of renewable energy and simultaneously improving efficiency, Green hydrogen will form an important bridge in the quest for decarbonisation with clean energy for a better tomorrow.

References

1. https://www.altenergymag.com/article/2009/04/the-history-of-hydrogen/555/

2. https://www.energy.gov/eere/fuelcells/hydrogen-fuel-basics

3. https://www.nationalgrid.com/stories/energy-explained/hydrogen-colour-spectrum

4. https://www.weforum.org/publications/net-zero-industry-tracker-2023/

5. https://hydrogencouncil.com/en/why-hydrogen/

6. https://www2.deloitte.com/content/dam/Deloitte/at/Documents/presse/at-deloitte-wasserstoffstudie-2023.pdf