www.industryemea.com

22

'21

Written on Modified on

Revolve Hybrid Compound Microscope Uses Negative-Stiffness Vibration Isolation to Stabilize Imaging in Vibration-Challenged Environments

The recently released Revolve hybrid microscope from Echo Laboratories – which has generated considerable interest because it combines the functionality of both upright and inverted microscopes into one instrument – supports the use of Negative-Stiffness vibration isolation when the microscope is being used in vibration-compromised environments.

The compound microscope has evolved from an instrument providing simple contrast viewing, into super-resolution systems capable of sub-diffraction accuracy. Its two platforms, upright and inverted, can be found in most laboratories doing cellular research, such as in biotech and pharmaceutical. Upright microscopes are used for viewing glass slides, and inverted for viewing live cells in Petri dishes. Despite its imaging advances, the basic architecture of the compound microscope has not substantially been modified in centuries.

This has now changed, with the recent release of the Revolve hybrid compound microscope, developed by Echo Laboratories (Echo), which has set a new precedent in microscope usability and design. The Revolve combines the full functionality of both upright and inverted microscopes in one instrument, and can switch between the two imaging modes relatively swiftly and easily. This gives the flexibility to view many types of samples with one microscope to a level of 300 – 350 nanometers resolution.

Revolve combines the full functionality of both upright and inverted microscopes.

“More than 70 percent of labs end up having both inverted and upright microscopes,” said Jeff Huber, Director of Sales for Echo Laboratories. “But both uprights and inverts use similar objectives, illuminators, position systems and cameras. Why duplicate all of these expensive components? And why take up valuable lab space with two instruments? So, Echo Laboratories engineered a way to merge these two systems into one unified instrument, which is the Revolve microscope.”

Brightfield, Phase Contrast and Epifluorescence Imaging with iPad and Wireless Upload

This is a compound, infinity-path microscope, with applications for brightfield, phase contrast, and epi-fluorescence imaging. Current glass selection includes the entire line of Olympus objectives. Due to the unique nature of the upright/inverted combination, both a high-NA and long-working-distance transmitted-light condensers are available to support phase and brightfield. A high-accuracy locking mechanism is used to securely hold the condenser assembly in place, while still allowing for easy removal by a single lever.

The instrument uses the Apple iPad tablet for control, interface, storage and display of images, replacing the traditional eyepiece, for easier viewing. “In microscopy, image quality is paramount,” added Huber. “The iPad tablet provides beautiful, crystal-clear views through its world-class retina display.”

In brightfield mode the iPad camera is optically coupled to the lightpath, providing sharp, color balanced, auto-exposed images. Optical coupling is set to provide the full objective field within the iPad camera FOV, with pinch+zoom available should the user want a traditional square view. On-screen controls are provided for color balance, brightness and contrast.

In fluorescent mode, the Revolve uses a high-sensitivity quantitative monochrome camera, which is wirelessly connected to the iPad display, providing a no-latency view when scanning a fluorescent plate or slide. High-power discrete LEDs provide fluorescence excitation. Fluorescent wavelengths are specified by light cube, with a cube and filter block set provided for popular fluorescent excitation/emission spectra.

“The user interface for fluorescence includes enough control to be useful, but avoids the excessive detail usually found on older imaging programs,” continued Huber. “The user will not have to worry about parallel shift voltage settings, or pre/post sensor clearing options just to capture an image.”

Images and data can then be stored on the iPad, transferred to memory sticks, or wirelessly and directly uploaded to various cloud platforms.

Negative-Stiffness Vibration Isolation

A typical laboratory will almost always position a microscope on a vibration isolation platform. Isolating sensitive imaging equipment against low-frequency vibration has become increasingly more vital to maintaining imaging quality and data integrity. Ever more frequently, laboratory researchers are discovering that conventional air tables are not able to adequately cancel out the lower frequency perturbations derived from air conditioning systems, outside vehicular movements and ambulatory personnel.“We are putting the Revolve microscope into many different environments that have diverse vibration issues,” explained Huber. “Because the instrument is capable of measuring to sub-micron levels with clarity, any vibration can disrupt imaging. For some time, we have been using Negative-Stiffness vibration isolation for our Revolve demonstrations to potential clients, as well as recommending it for their permanent Revolve microscopy applications.”

Because of its very high isolation efficiencies with low-hertz vibrations in both vertical and horizontal vectors, Negative-Stiffness vibration isolation enables sensitive instruments, like Revolve, to be located wherever a production facility or laboratory needs to be set up, whether that be in a basement, or on a building’s vibration-compromised upper floors.

Negative-Stiffness isolators do not require electricity or compressed air. There are no motors, pumps or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

Negative-Stiffness vibration isolator.

If equipment can be isolated from vibrations without having to deal with compressed air or electricity, then it makes for a system that is simpler to transport, and easier to set-up and maintain.

What is very advantageous about Negative-Stiffness isolators is that they achieve a high level of isolation in multiple directions. Negative-Stiffness isolators have the flexibility of custom tailoring resonant frequencies to 0.5 Hz* vertically and horizontally (with some versions at 1.5 Hz horizontally).

(*Note that for an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with increase in the vibration frequency. The natural frequency is more commonly used to describe the system performance.)

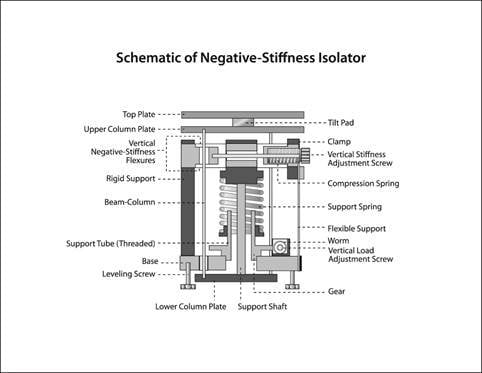

Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a Negative-Stiffness mechanism. The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. A beam-column behaves as a spring combined with a negative-stiffness mechanism. The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and very high internal structural frequencies.

Negative-Stiffness isolators deliver very high performance, as measured by a transmissibility curve. Vibration transmissibility is a measure of the vibrations that are transmitted through the isolator relative to the input vibrations. Negative-Stiffness isolators, when adjusted to 0.5 Hz, achieve approximately 93 percent isolation efficiency at 2 Hz; 99 percent at 5 Hz; and 99.7 percent at 10 Hz.

Schematic of a Negative-Stiffness isolator.

“Not only does Negative-Stiffness provide excellent vibration isolation values, but it fits with the microscope’s more compact form factor,” said Huber. “It is very portable, and adapts easily to virtually any vibration-challenged environment. These factors have helped us meet our customers’ needs with more versatility than we could with other vibration isolation methods.”

www.minusk.com