www.industryemea.com

26

'25

Written on Modified on

Baumüller showcases PowRex high-torque drive system at K 2025

At K 2025, Baumüller presents PowRex drive with Nidec Desch Tevox, boosting shredder efficiency, energy savings, and retrofit options.

www.baumueller.com

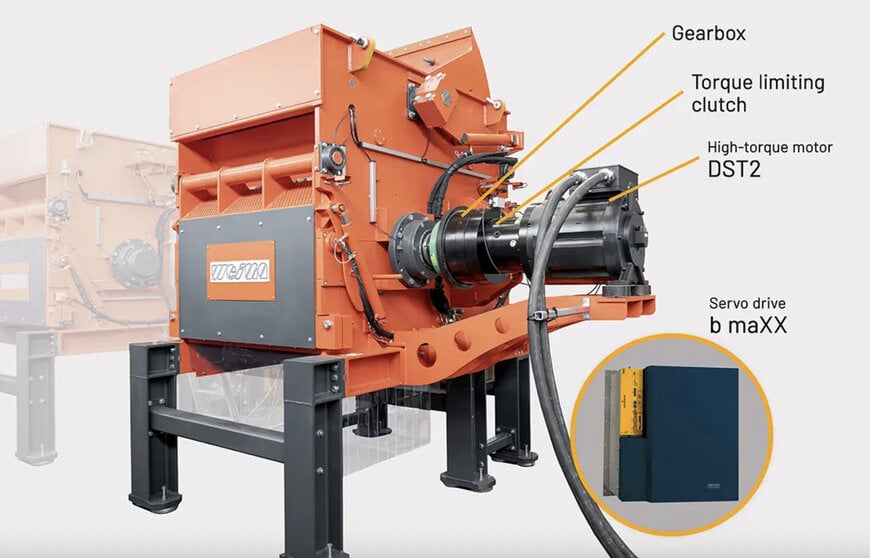

Innovative high-torque drive system: The PowRex drive system from Baumüller will be shown LIVE at K 2025 together with a Tevox® direct drive from Nidec Desch on a W5.22 shredder from WEIMA

High-throughput shredders with all-electric drive

From October 8 to 15, 2025, visitors to K in Düsseldorf will have the opportunity to find out about recycling as well as trends in the plastics industry. The Baumüller Group will be presenting an innovative high-torque drive system for shredders to manufacturers of recycling machines at its stand in Hall 11, Stand A45. With the PowRex/Tevox combination, Baumüller and the expert for customized gear and clutch technology Nidec DESCH combine their respective know-how.

The powerful PowRex drive system from Baumüller, comprising a DST2 high-torque motor and a b maXX servo drive, in conjunction with the robust Tevox, a gearbox/slip clutch combination from Nidec DESCH, achieves a high level of efficiency, thereby maximizing energy efficiency.

WEIMA: Single-shaft shredder with electric high-torque drive

High peak and rated torques, a specially developed motor design and a precisely matched drive train - these are crucial requirements for modern shredder drives, which must also be reliably met when processing recycling materials. An all-electric system solution with a high-torque drive combines these advantages in a compact unit. Thanks to the high-torque motor, powerful torque is available even at low speeds. The precise connection of the drive to the rotor shaft optimizes power transmission, increasing drive power and efficiency. For recycling companies, this innovative drive system means more economical operation, less downtime, and more sustainable processing of valuable raw materials.

At the trade fair in Düsseldorf, WEIMA will be presenting a shredding system from the W5 series in Hall 9, Stand A39 - equipped with the PowRex drive system from Baumüller and the Tevox® direct drive from Nidec Desch. With the new high-torque drive system, WEIMA is expanding its drive portfolio specifically for the requirements of the recycling industry.

Modernization instead of new acquisition

In order to benefit from the energy efficiency of the highly dynamic high-torque drive system, it is not necessarily necessary to purchase a new shredding system. If the mechanics are still in order, a shredder can also be brought up to date by retrofitting the drive system. And this can be done at significantly lower cost and often faster than buying a new one.

K 2025, October 8–15, 2025 – Düsseldorf Exhibition Center, Düsseldorf

Baumüller Group

Hall 11, Booth A45

WEIMA Maschinenbau GmbH

Hall 9, Stand A39

www.baumueller.com

High-throughput shredders with all-electric drive

From October 8 to 15, 2025, visitors to K in Düsseldorf will have the opportunity to find out about recycling as well as trends in the plastics industry. The Baumüller Group will be presenting an innovative high-torque drive system for shredders to manufacturers of recycling machines at its stand in Hall 11, Stand A45. With the PowRex/Tevox combination, Baumüller and the expert for customized gear and clutch technology Nidec DESCH combine their respective know-how.

The powerful PowRex drive system from Baumüller, comprising a DST2 high-torque motor and a b maXX servo drive, in conjunction with the robust Tevox, a gearbox/slip clutch combination from Nidec DESCH, achieves a high level of efficiency, thereby maximizing energy efficiency.

WEIMA: Single-shaft shredder with electric high-torque drive

High peak and rated torques, a specially developed motor design and a precisely matched drive train - these are crucial requirements for modern shredder drives, which must also be reliably met when processing recycling materials. An all-electric system solution with a high-torque drive combines these advantages in a compact unit. Thanks to the high-torque motor, powerful torque is available even at low speeds. The precise connection of the drive to the rotor shaft optimizes power transmission, increasing drive power and efficiency. For recycling companies, this innovative drive system means more economical operation, less downtime, and more sustainable processing of valuable raw materials.

At the trade fair in Düsseldorf, WEIMA will be presenting a shredding system from the W5 series in Hall 9, Stand A39 - equipped with the PowRex drive system from Baumüller and the Tevox® direct drive from Nidec Desch. With the new high-torque drive system, WEIMA is expanding its drive portfolio specifically for the requirements of the recycling industry.

Modernization instead of new acquisition

In order to benefit from the energy efficiency of the highly dynamic high-torque drive system, it is not necessarily necessary to purchase a new shredding system. If the mechanics are still in order, a shredder can also be brought up to date by retrofitting the drive system. And this can be done at significantly lower cost and often faster than buying a new one.

K 2025, October 8–15, 2025 – Düsseldorf Exhibition Center, Düsseldorf

Baumüller Group

Hall 11, Booth A45

WEIMA Maschinenbau GmbH

Hall 9, Stand A39

www.baumueller.com