www.industryemea.com

18

'17

Written on Modified on

Practical Approach to Control Waste in Manufacturing

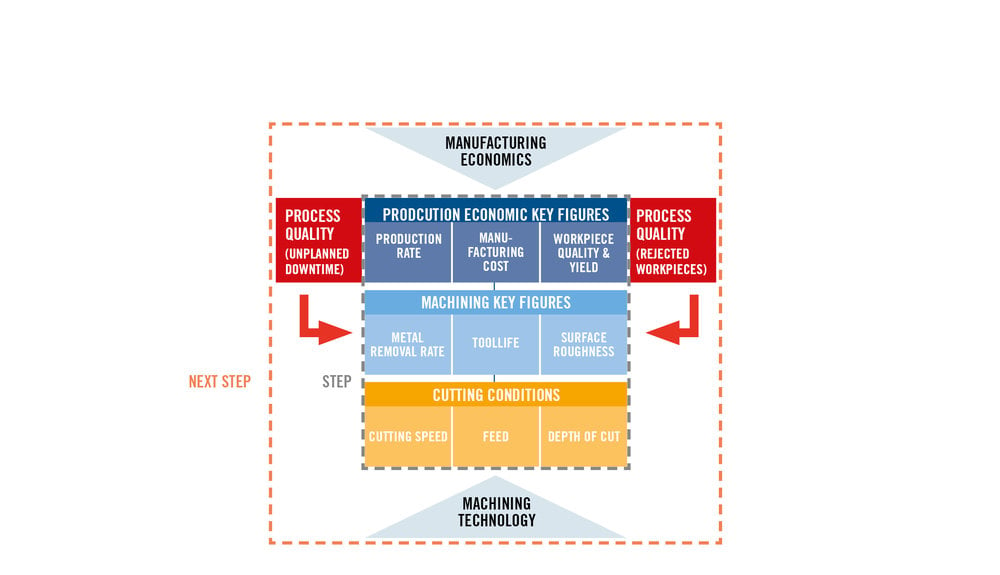

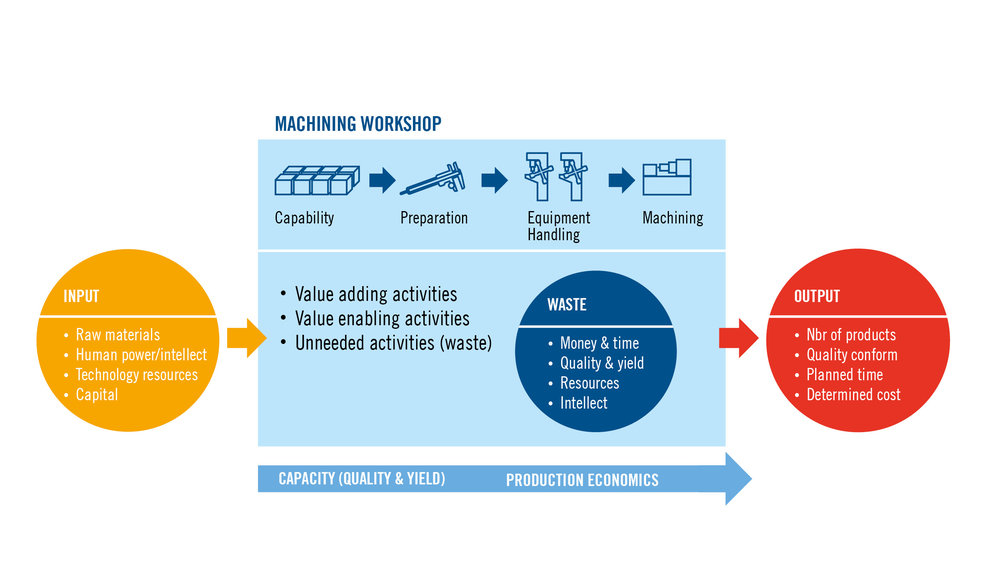

Manufacturers continually seek ways to maximise productivity and efficiency. Today, those efforts frequently involve high-level programs that employ buzzwords that include cloud computing, data-driven manufacturing, cyber-physical systems and Industry4.0. These advanced initiatives are excellent concepts and can produce impressive results. However, manufacturing realities often interfere with the implementation of such ambitious plans, and a critical reality is the presence of uncontrolled waste in the manufacturing process. Before discussing digitisation and optimisation, it is necessary for a manufacturer to examine its operations, determine where waste occurs, and develop methods to reduce or eliminate it. Controlling waste is the first step in preparing a manufacturing company for the adoption of sophisticated smart manufacturing strategies. Figure 1 – Total image of all elements and how they relate and interact, in a manufacturing plant (NEXT STEP model and concept).

Basics of production economics

Manufacturing consists of a series of transformation processes. A shop forms raw material into finished or semi-finished workpieces through a series of individual transformation operations such as forging, welding or machining. A number of individual elements comprise each operation. The basic elements of machining, for example, include the cutting tool, machine tool, fixtures and coolant supply. Together these elements form a machining system that gets support from related equipment and components in a production system.

Planning, programming and economic management functions surround the production system to form a production environment. The key element of a production environment is people. Although manufacturing today widely utilises computers, robots and other advanced technology, people make the decisions that control the environment overall.

The machining process is based on technical application details regarding tool selection, cutting conditions, programming and workpiece material and fixturing. Other key details include production volume requirements and the specified quality of finished workpieces.

Linking technical application details with economic concerns is called production economics. The goal of the science of production economics is to balance all the factors involved. While technical elements produce desired results in terms of workpiece quality, quantity and timeliness, the operations must be carried out at a cost that enables a business to thrive.

Achieving the balance of output and cost in machining progresses through three phases. The first phase is establishing a reliable machining process. It is essential to minimise unexpected occurrences such as broken tools, uncontrolled chips and resulting destroyed workpieces. A workshop establishes operational reliability by choosing tools with load capacity that meets or exceeds the mechanical, thermal, chemical and tribological loads generated in the machining process.

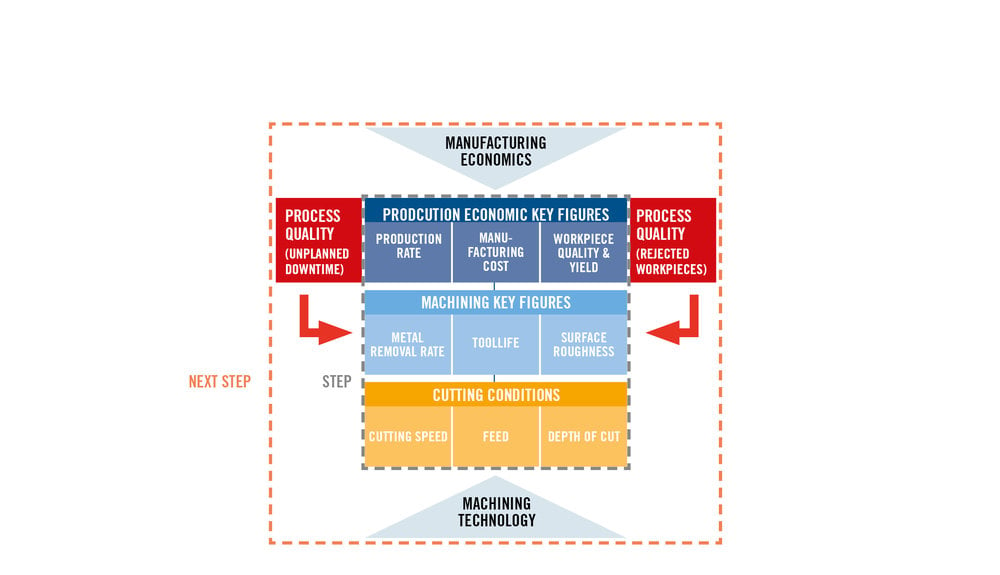

Figure 2 – Total machinability model developed in STEP.

HQ_ILL_Machinability _model

Phase two in achieving balanced production economics involves choosing cutting conditions that reflect the constraints put on the machining process by real-world circumstances. The theoretical capabilities of a cutting tool are broad. But specific workshop realities constrain the range of effective application parameters.

For example, the capabilities and performance of a tool vary according to the amount of power possessed by the machine tool that is applying it; the machining characteristics of the workpiece material; or the configuration of a part that may be prone to vibration or distortion. Although there is a vast selection of cutting conditions that will work in theory, unfortunately constraints posed by reality will narrow the range of trouble-free choices.

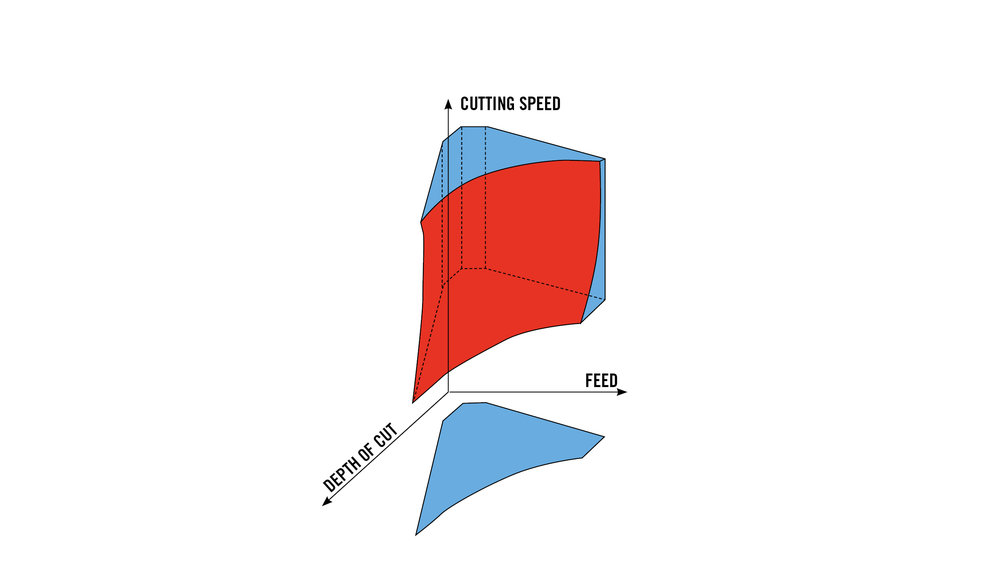

Figure 3 illustrates a large selection or volume of cutting speeds, depths of cut and feeds that has been carved into a smaller selection and reduced volume in recognition of various realities of a specific cutting application.

Figure 3 – 3D illustration that shows the collection of all cutting condition combinations that can be used within the constraints coming from the cutting environment.

HQ_ILL_Machining_Process_cutting_conditions

Applying cutting conditions outside the application constraints of the specific situation will have negative economic consequences, including higher costs and lower productivity. Perhaps 90 percent of the problems experienced during machining result from a lack of respect for the constraints that workshop realities place on the cutting process.

When cutting conditions do not exceed the constraints imposed by workshop realities, the operation is safe from a technical perspective. However, not every technically safe combination of cutting conditions will produce the same economic result. Changing cutting conditions changes the cost of the machining process. Moving to more aggressive but still technically safe cutting conditions will increase the output of finished workpieces, but after a certain point however, productivity will decline because the aggressive cutting parameters also will result in shorter tool life. The output of parts over time then will decline as well, because more time will be spent changing worn tools.

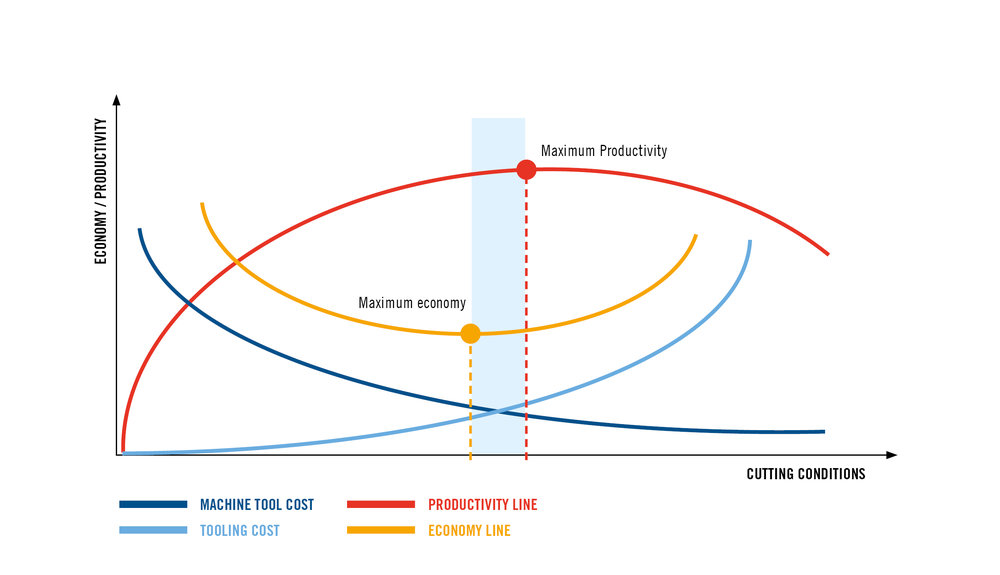

Somewhere there is a combination of cutting conditions that result in a balance of productive output and manufacturing cost. Figure 4 shows the relationship between cutting conditions, productivity and tool and machine costs. (The graph concentrates only on elements that vary as cutting conditions change – material, overhead and administration and engineering costs are not included.) More aggressive conditions are at the right of the axes and higher productivity at the top. The pale blue band at the middle of the graph indicates where cutting conditions produce a balanced blend of productivity (highest output) and economy (lowest cost).

Figure 4 – relationship between cutting conditions, productivy and machining costs. This figure shows a simplified model, not taking into account waste factors.

HQ_ILL_Machining_Process_relationship_cutting_conditions_productivity_machining_costs

Accordingly, the third phase of achieving balanced production economics involves determining the optimal combination of cutting conditions for a given situation. It is essential to take into account all the factors in the machining operation to establish a working domain where cutting parameters provide the desired levels of productivity and economy.

The effect of waste on production economics

Unfortunately, the elegant scientific methods of balanced production economics operate at the mercy of waste in the manufacturing system. Waste destroys the balance and occurs in many ways. For example, it is a waste of energy and power when a 60kW machine tool is used in an ongoing application that requires only 15kW. In another situation, when finished workpieces do not meet required levels of quality, the time, money and resources invested in the process are wasted in pursuit of an unacceptable result. Similarly, manufacturing workpieces that needlessly exceed required levels of quality is wasteful, because achieving increased quality increases cost.

A less obvious and less understood occasion of waste is the underuse or misuse of intellectual resources. Certain personnel in a company may possess knowledge or skills that will help the company achieve its goals, but for reasons ranging from poor communication to intra-company politics, the knowledge and skills are not shared and therefore go to waste.

Waste reduction tools

After waste is identified and categorized, a shop should create a plan to reduce or eliminate it. There exists a wide range of tools that enable a manufacturer to pinpoint, quantify, and minimise wasteful practices. For example, analysis of tool usage, manipulation and deterioration will point out trouble areas.

Such analyses have shown that in some cases as much as 20 percent to 30 percent of the tools that personnel defined as worn out were in fact still viable – the remaining tool life was wasted. Establishing clear tool wear criteria and communicating the standards to shop personnel will significantly reduce wasted tool life.

Similarly, machine downtime analyses quantify the time spent in activities such as setup, programming and tool changing. These analyses often indicate that as much as 50 percent to 60 percent of machine downtime is avoidable through a better understanding, execution and coordination of these necessary but time-consuming activities.

The use of interviews, surveys and training programs can uncover a lot of useful information when dealing with personnel issues that lead to waste of intellectual resources as well as unrealized knowledge and skills. As a result, employees perform their jobs better and build capabilities that maximise personnel productivity.

Management of value-adding, value-enabling, and unneeded activities

At the start of the 20th century, American industrial engineer Fredrick Taylor studied workshop operations and proposed that productivity improvement be driven by eliminating any activities in a process that do not add value to the final product. Modern “lean” manufacturing guidelines follow this same line of thinking.

In machining operations, the only true value-adding activity occurs when the tool is actually cutting metal and making chips. Other actions such as part loading and fixturing, termed value-enabling activities, do not directly add value to the manufactured product but are required to allow the value-adding activity to occur.

A third group of activities in the machining system are those that are unneeded. These activities neither create value nor enable creation of value, but rather consume resources with no benefit. They are purely occasions of waste. Problem solving is an example of unneeded activity. If a process is properly designed and controlled in the first place, there will be no problems and no time wasted solving them.

Figure 5 – Schematic picture of a machining workshop and all the elements related to it.

HQ_ILL_Machining_process_workshop

Conclusion

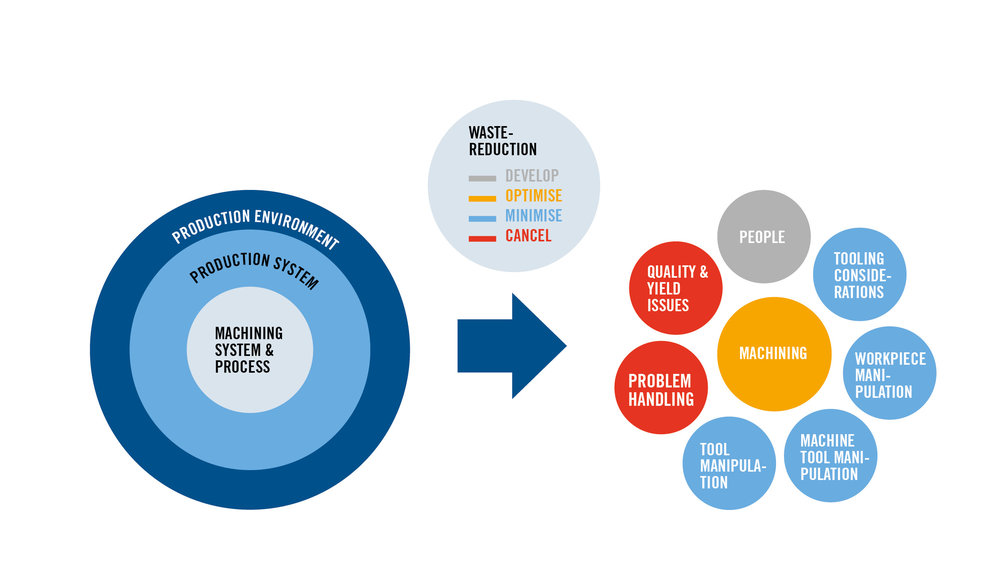

For much of the past, unneeded activities were accepted as part of the manufacturing process and not recognized as significant disruptors of the achievement of balanced production economics. Presently, attention is turning to the elimination or minimisation of unneeded activity. The focus of productivity or capacity planning is on eliminating unneeded activities, minimizing value enabling activities and optimising value adding activities. (See Figure 6)

Figure 6 – Overview of value adding adding activities (orange), value enabling activities (blue) and waste activities (red). The people factor (grey) is the key factor to reach optimum achievement of manufacturing top performance.

HQ_ILL_Machining_system_process

When waste is eliminated, theoretical production economics become practical production economics. At that point, progress in production economics can be applied directly to company success. However, in the effort to eliminate every occasion of waste, caution is necessary. It is important to quantify the return on investment of waste reduction activities. Totally eliminating a certain incidence of waste might involve an investment that is so large that from an economic perspective it may be better to accept the waste, or a portion of it, and live with it. Such decisions are made following appropriate quantitative analysis as well as intra-company discussions regarding how the decisions will affect company goals and philosophies.

Sidebar:

Seco Consultancy Services

As manufacturing products become more sophisticated, users need increasing amounts of application assistance to realise maximum benefits from the new technologies. In machining, the initial level of assistance is guidance in the selection of the right tool for a certain operation. After a tool is selected, further information facilitates choice of optimal cutting conditions, use of coolant and other considerations. Then, if a tool fails to function as expected in that operation, the tool supplier can provide troubleshooting help. These three modes of assistance make up traditional tooling services.

When tooling service expands from a single application to cover a process in which a workpiece is subject to multiple operations on one or more machines, end users require guidance in arranging the sequence of operations, workpiece manipulation and other factors to maximise efficiency and productivity. That level of assistance can be called engineering services.

More and more frequently, manufacturers are seeking direction in improving functions, output and cost control for an entire shop or organization. In these cases, some independent consulting companies perform what they describe as management or manufacturing consulting. However, to do a true evaluation of a manufacturing organization, it is essential to fully understand the business’s core operations.

Applying its long and extensive understanding of machining processes and tooling, Seco has been providing traditional tooling services, engineering services and to some extend bigger-picture consulting for decades. Those services were offered on a contingent or situation-specific basis, but in 2016, Seco formed its Consulting Services to provide its customers with a more streamlined and responsive array of manufacturing services.

Seco Consulting Services include a wide range of specific resources and delivery methods. Tool selection and application assistance is available online around the clock to meet immediate productivity needs on the shop floor.

Engineering services can begin with electronic communication and extend to on-site visits if necessary. Seco Consulting Services also can include comprehensive analysis and guidance involving the operation of every function in a workshop. Those services can include consultation on machine tool maintenance, workshop layout, logistics and organizational functions. Advice on personnel skill and knowledge issues, and the relationship of the manufacturing techniques employed to the organization’s production strategies and cost considerations can be included as well.

Each Seco Consultancy relationship is based on the NEXT STEP concept but also custom-tailored to the participating organization’s specific needs, and exists as a dialog between Seco and the customer aimed at achieving a common goal.