Quickparts Expands US Operations with New Aerospace & Defence Centre and Quick Mould Launch

Dual investment boosts SLA capacity and introduces rapid production-grade moulding across North America.

quickparts.com

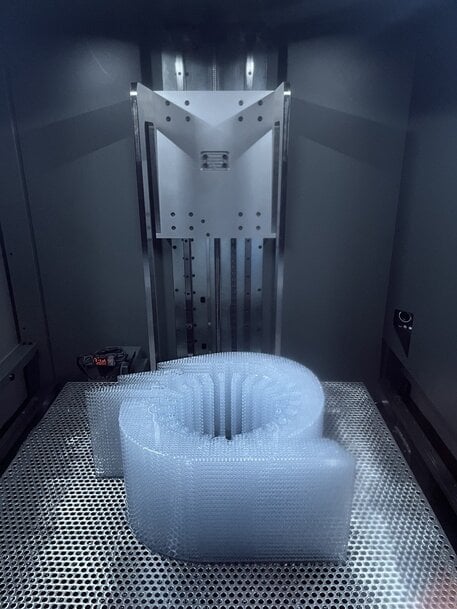

Quickparts SLA

Quickparts, a leader in on-demand manufacturing, today reinforced its commitment to “Limitless Manufacturing” with the completion of a significant US$2.5 million investment in new equipment and facility upgrades at its Seattle, WA headquarters. The improvements formally establish the site as an Aerospace & Defence Centre of Excellence, strengthening the company’s long-standing expertise in high-fidelity casting patterns and advanced stereolithography (SLA). At the same time, Quickparts is officially launching its Quick Mould solution — announced last month in EMEA — across North America, delivering production-quality moulded parts in as little as five days.

Together, these initiatives align under one objective: accelerating global manufacturing with precision, speed, and reliability.

“For more than three decades, we’ve been driving and redefining global manufacturing — delivering continuous innovation across on-demand services,” said Avi Reichental, CEO of Quickparts. “As we continue to build upon our rich history and proven track record of innovation to help companies rapidly address their most complex manufacturing challenges, today’s announcements reflect this ongoing vision and commitment to our customers.”

Quickparts Investment Casting

Seattle Expansion: US Hub for Precision Investment Casting Patterns and Advanced SLA

With this latest investment, Quickparts has expanded its QuickCast® investment casting patterns and next-generation SLA capacity in the Americas. This enables higher throughput, increased repeatability, and even greater fidelity for precision investment casting patterns used in drone, satellite, propulsion, aviation, and defence systems.

The expansion builds on Quickparts’ 35-year legacy of delivering advanced manufacturing solutions globally, including decades of producing high-fidelity casting patterns. The enhanced operation strengthens the company’s ability to support aerospace and defence programmes where consistency, dimensional accuracy, and repeatability are mission-critical.

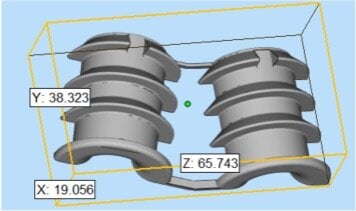

Case Study - CAD

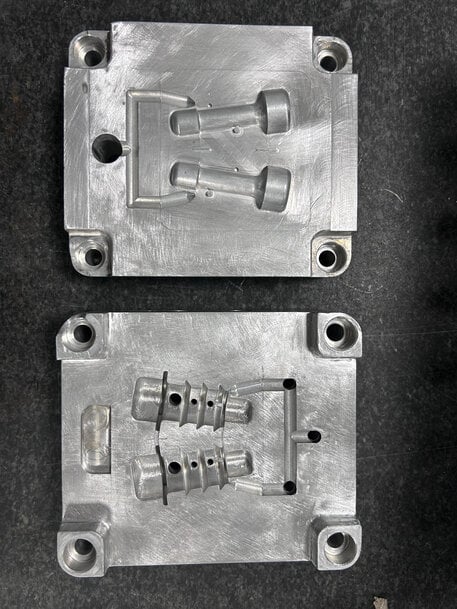

Case Study - Tool

Global Expansion of Quick Mould: Production-Quality Parts in as Little as Five Days

Coinciding with the Seattle expansion, Quickparts is introducing Quick Mould to customers across North America, following its strong uptake in Europe. Quick Mould delivers production-quality injection-moulded parts in as few as five days, enabling engineers to compress design cycles, validate materials earlier, and respond quickly to programme changes — all supported by Quickparts’ engineering teams and expert DFM guidance.

Quick Mould uses rapidly machined aluminium tooling and engineering-grade thermoplastics to move customers from design to functional, production-grade parts at unprecedented speed.

This process has already delivered measurable customer results, including:

- 1-day design-change cycle using PA66 GF50

- 4-day turnaround for high-stress automotive components

- A luxury vehicle button redesigned, tooled, and moulded in four days

These achievements demonstrate Quickparts’ commitment to helping manufacturers reduce development time and maintain momentum, even under demanding schedules.

“The addition of enhanced SLA capabilities and the Seattle expansion represent significant steps in strengthening our global manufacturing footprint,” said Peter Jacobsen, EMEA President at Quickparts. “Seeing the strong momentum of Quick Mould across Europe, I’m especially excited that our multinational customers will now have access to this transformative technology.”

Quick Mould is now available to customers across North America and Europe.

www.quickparts.com