www.industryemea.com

11

'17

Written on Modified on

New bearing and ball screw innovations from NSK

NSK will use the forthcoming EMO 2017 exhibition (Hanover, Germany, 18-23 September) to shine the spotlight on a number of new and recent innovations for the global machine tool market. These will include advances in angular contact ball bearings for main spindles, deep groove ball bearings for spindle motors, and toughened ball screws specifically for injection moulding machines. Also featured on the NSK booth (Hall 7, Stand D12) will be a working demonstration of a condition monitoring system (CMS) with real-time vibration analysis displayed on a monitor.

NSK is the only manufacturer of its type to offer a complete development and supply service for the precision motion components found within machine tools, including bearings, ball screws and linear guides. Among the principal exhibits at EMO 2017 will be ‘SURSAVE’, a newly developed outer ring cage for NSK angular contact ball bearings used in main spindle applications. SURSAVE has been designed to help lower non-repeatable runout (NRRO) by 50% compared with conventional units. It also reduces torque by 20%, generates less heat, operates at high speed, and contributes to high-precision processing.

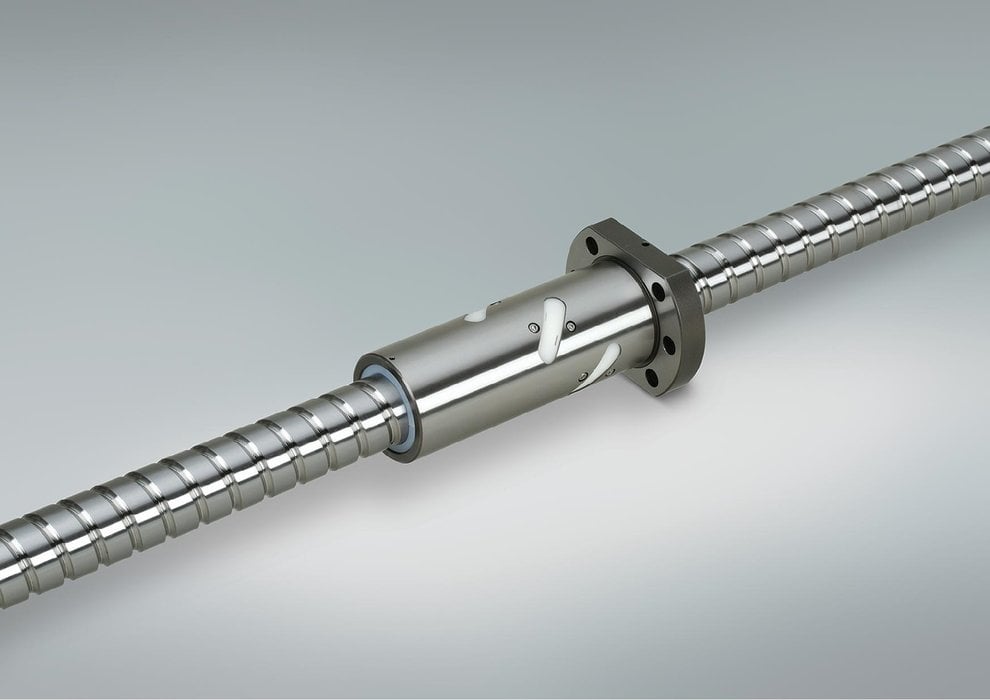

For machine builders seeking the latest ball screw solutions, NSK will display its recently released S-HTF Series, which offers more than double the service life and 1.3 times greater dynamic load capacity than the company’s previous-generation product. These performance attributes have been achieved thanks to the use of a new steel material (named Tough Steel – TF) for the screw shaft that delivers an optimised combination of hardness and resilience. S-HTF ball screws are intended for high-load applications, such as those found in plastic injection-moulding machines and forming presses.

A brand new ball screw for machine tool applications will also take the spotlight at EMO. This DIN-standard, high-speed (160,000 dn value) ball screw will offer shaft diameter sizes ranging from 32 to 63 mm, and leads from 10 to 30 mm. More information will be available to those visiting the booth.

Visitors to the NSK booth will also see a working demonstration of a CMS to show how zero downtime can be achieved. A trio of single-axis moving tables showing normal, early-stage damage and damaged ball screws, will be paired with vibration sensors. Visitors will be able to view real-time vibration analysis displayed on a monitor, with deviations clearly shown between normal and damaged ball screws.

For directors, managers and engineers at machine tool OEMs, or at companies using machine tools, the latest NSK innovations for the next-generation of machine tools will make a visit to EMO 2017 extremely worthwhile. The company will have an expert team of professionals available on the booth who will be happy to discuss any specific applications.