www.industryemea.com

12

'25

Written on Modified on

Modular Grinding System Simplifies Mineral Processing Setup

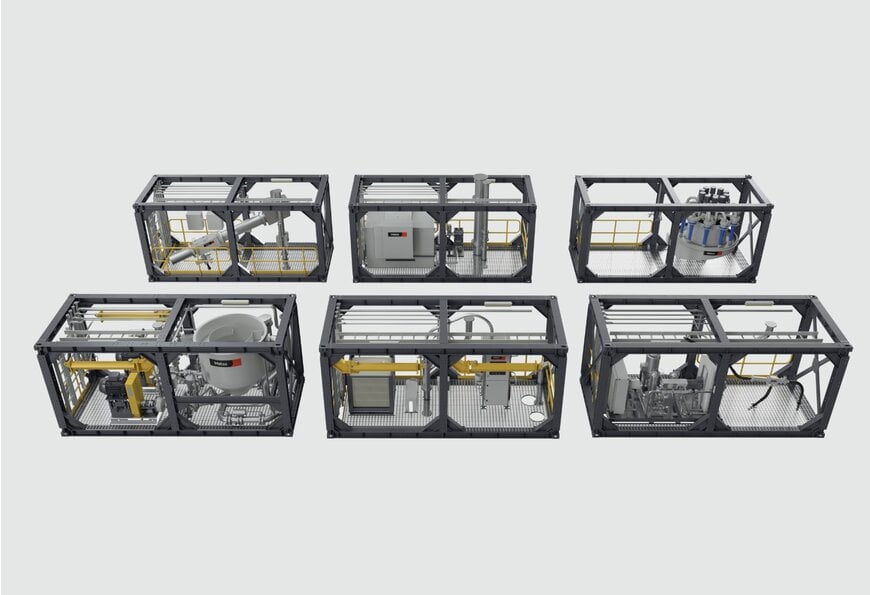

Metso introduces a configurable system built from container-sized modules that speed installation, reduce project costs, and integrate seamlessly with multiple grinding mill technologies.

www.metso.com

In mineral processing plants, grinding circuits must support a wide range of mill types while maintaining high uptime, predictable performance, and safe operation. Installation time and layout constraints often limit the flexibility of conventional grinding systems, especially when integrating pumps, hydrocyclones, samplers, or lubrication equipment. To address these challenges, Metso presented a new configurable grinding classification system, designed to standardize how key subsystems are delivered, installed, and commissioned.

Pre-Engineered Modules for Faster and Safer Installation

The system is based on pre-engineered modules that incorporate pumps, hydrocyclones, product samplers, particle size analyzers, mill lubrication units, and liquid resistance starters. Each module is engineered to correspond to the external dimensions of standard 20-foot or 40-foot ISO containers, which allows the equipment to be transported without custom packaging and positioned on site with conventional lifting equipment.

Because the modules are pre-designed and require no structural modification at the plant, installation steps are reduced compared with traditional on-site assembly. According to Metso, these standardized units enable installation up to four times faster and can reduce overall project cost by more than 20% compared with custom-built configurations. Faster installation also limits exposure to on-site mechanical work, which contributes to safer commissioning conditions.

The modules can be stacked, offering a compact layout option for facilities with limited floor space. This modular stacking is feasible because the modules share a unified structural envelope sized for the container footprint, enabling predictable load distribution and simplified platform design.

Supporting All Major Grinding Mill Types

The grinding classification system is compatible with all major mill technologies used in minerals processing, including Vertimill®, Stirred Media Detritor (SMD), HIGmill®, and conventional ball mills. By using standard module interfaces, operators can adapt the system to different classification stages or integrate new components as circuit requirements evolve.

The system is designed to be scalable, allowing plants to configure only the modules needed for the required capacity or classification duty. For operators or EPC contractors, this simplifies the selection and engineering process, reduces variability between sites, and supports more consistent lifecycle performance.

Streamlined Operations Through Configurability

By combining container-sized modules, reduced installation work, and compatibility with multiple mill types, Metso’s grinding classification system offers a standardized approach for plants seeking faster commissioning and predictable integration. Its configurability enables users to set up complete grinding classification loops without extensive civil works or custom fabrication, which is especially relevant in brownfield expansions or remote project environments where installation time and resources can be limited.

www.metso.com