www.industryemea.com

15

'25

Written on Modified on

Advanced Pump Technology Enhances Polymer Film Production

CIRCOR’s Zenith pumps reduce air infiltration and ensure uniform, high-quality multilayer films in food packaging and battery manufacturing.

zenith.de

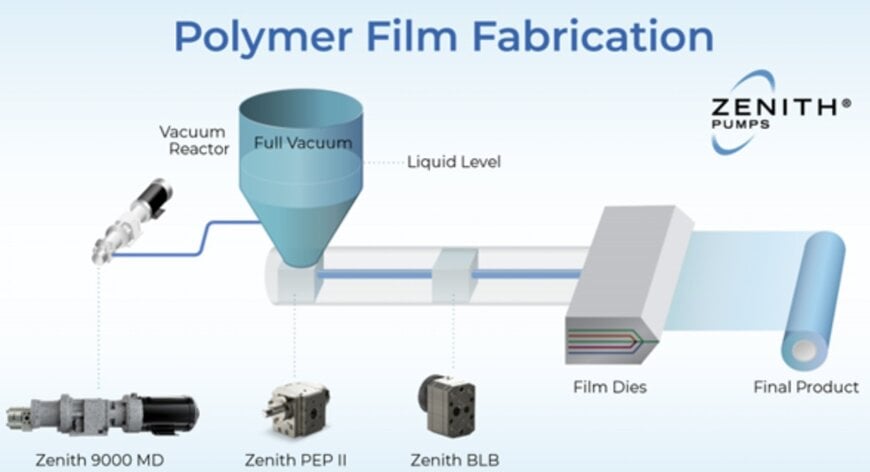

Polymer film production, critical to industries such as food packaging and battery manufacturing, increasingly relies on multilayer films with precise properties. A common challenge in these processes is air infiltration, which can introduce bubbles or gaps between layers, compromising structural integrity, barrier performance, and overall product durability. Zenith Pumps from CIRCOR provide advanced solutions to mitigate these issues, maintaining consistent polymer flow and ensuring uniform layer deposition in vacuum and low-pressure environments.

How Air Affects Film Quality

Air infiltration can create weak points in polymer films, including:

- Compromised barrier properties: Bubbles reduce effectiveness against moisture, light, or gases.

- Structural weaknesses: Voids can cause tearing or punctures, critical for battery or food packaging applications.

- Thickness variations: Uneven film layers lead to quality control issues and material waste.

Ensuring consistent, high-quality films requires precise control over the flow of molten polymer and the prevention of air entry throughout the production system.

Role of Pumps in Maintaining Film Integrity

Pumps are essential for sustaining continuous, uniform flow in polymer extrusion, casting, or blowing processes. Traditional pumps with mechanical seals often introduce air into low-pressure or vacuum systems. Sealless magnetic drive (mag-drive) pumps, such as those offered by Zenith, address this challenge by eliminating mechanical seals entirely. Magnetic coupling transmits torque without exposing the polymer to the external environment, significantly reducing the risk of air infiltration.

Solutions for Multilayer Film Applications

1. Magnetic Drive Pumps for Vacuum Systems

Zenith’s mag-drive pumps are mounted directly to vacuum reactors to minimize connection points and maintain a closed system. By isolating the polymer from the atmosphere, these pumps prevent bubbles while maintaining consistent flow and pressure, essential for uniform multilayer films.

2. Triple Lip Seal Technology for High-Pressure Stages

In sections requiring higher pressures, pumps equipped with triple lip seals provide an additional layer of protection. A barrier fluid between the seals prevents air from reaching the polymer, ensuring uniformity across complex multilayer configurations. This is particularly important for films with up to seven layers, where each layer has a specific function, such as light or moisture blocking.

3. Precision Pumping for Consistent Layer Thickness

Maintaining consistent flow and pressure across multiple layers prevents variation in film thickness. Zenith pumps achieve high mechanical efficiency and low pulse operation, enabling precise deposition of each layer, reducing scrap, and maintaining product specifications.

Benefits of Advanced Pump Implementation

By integrating mag-drive and triple lip seal pump technologies, manufacturers achieve improved polymer film quality, reduced waste, and increased production efficiency. The ability to control flow, pressure, and layer uniformity allows for reliable fabrication of multilayer films, from food packaging to battery cell applications. Zenith Pumps provides the technical performance necessary to meet the demands of modern polymer film production while minimizing defects and operational interruptions.

www.zenith.de

Role of Pumps in Maintaining Film Integrity

Pumps are essential for sustaining continuous, uniform flow in polymer extrusion, casting, or blowing processes. Traditional pumps with mechanical seals often introduce air into low-pressure or vacuum systems. Sealless magnetic drive (mag-drive) pumps, such as those offered by Zenith, address this challenge by eliminating mechanical seals entirely. Magnetic coupling transmits torque without exposing the polymer to the external environment, significantly reducing the risk of air infiltration.

Solutions for Multilayer Film Applications

1. Magnetic Drive Pumps for Vacuum Systems

Zenith’s mag-drive pumps are mounted directly to vacuum reactors to minimize connection points and maintain a closed system. By isolating the polymer from the atmosphere, these pumps prevent bubbles while maintaining consistent flow and pressure, essential for uniform multilayer films.

2. Triple Lip Seal Technology for High-Pressure Stages

In sections requiring higher pressures, pumps equipped with triple lip seals provide an additional layer of protection. A barrier fluid between the seals prevents air from reaching the polymer, ensuring uniformity across complex multilayer configurations. This is particularly important for films with up to seven layers, where each layer has a specific function, such as light or moisture blocking.

3. Precision Pumping for Consistent Layer Thickness

Maintaining consistent flow and pressure across multiple layers prevents variation in film thickness. Zenith pumps achieve high mechanical efficiency and low pulse operation, enabling precise deposition of each layer, reducing scrap, and maintaining product specifications.

Benefits of Advanced Pump Implementation

By integrating mag-drive and triple lip seal pump technologies, manufacturers achieve improved polymer film quality, reduced waste, and increased production efficiency. The ability to control flow, pressure, and layer uniformity allows for reliable fabrication of multilayer films, from food packaging to battery cell applications. Zenith Pumps provides the technical performance necessary to meet the demands of modern polymer film production while minimizing defects and operational interruptions.

www.zenith.de