www.industryemea.com

15

'25

Written on Modified on

Plasma-Based Coatings Replace PFAS in Surface Treatments

PLASRECO, led by AIMPLAS, applies atmospheric plasma and silicon chemistry to replace PFAS-based functional coatings in textiles, leather, and packaging.

www.aimplas.net

The PLASRECO project, coordinated by AIMPLAS, investigates PFAS-free functional coatings for packaging, leather, and textile applications using atmospheric plasma deposition of silicon-based materials. The approach targets water repellence and stain resistance while reducing chemical use and aligning surface treatment processes with European regulatory and sustainability requirements.

Regulatory pressure reshapes functional surface treatments

Functional coatings that deliver water repellence, stain resistance, or non-stick behavior are widely used in packaging, leather, and textile manufacturing. Many of these properties have traditionally relied on perfluoroalkyl and polyfluoroalkyl substances (PFAS), a class of chemicals increasingly restricted in the European Union due to their environmental persistence, bioaccumulation, and toxicity. As regulatory measures progress toward bans and tighter limits, manufacturers face the challenge of maintaining surface performance while eliminating PFAS from their processes.

PLASRECO was initiated to respond to this shift by developing alternative coating systems that comply with emerging chemical safety requirements without requiring fundamental changes to existing production lines.

Atmospheric plasma as a low-chemical deposition route

At the core of the project is atmospheric plasma technology, used to deposit nanometric functional layers onto substrates. Unlike conventional wet-chemical coating processes, atmospheric plasma enables surface modification with significantly reduced chemical consumption. The process operates at ambient pressure, avoiding vacuum systems and supporting continuous, inline integration in industrial environments.

The plasma-based approach is compatible with a broad range of substrates, including porous and flexible materials such as leather, textiles, and paper. This versatility is particularly relevant for sectors where coating uniformity and adhesion on non-rigid surfaces are technically demanding.

Organosilicon chemistry tailored for plasma application

To replace PFAS-derived functionalities, PLASRECO focuses on the development of new organosilicon monomers specifically designed for atmospheric plasma deposition. These monomers are engineered to form stable, crosslinked coatings under plasma conditions, targeting durability and reproducibility across industrial batches.

Performance evaluation includes resistance to abrasion, exposure to humidity, and thermal variation—conditions commonly encountered in footwear, textile finishing, and packaging use. The objective is to achieve functional parity with PFAS-based treatments while meeting safety and environmental criteria defined by European regulations.

Collaboration between surface science and polymer expertise

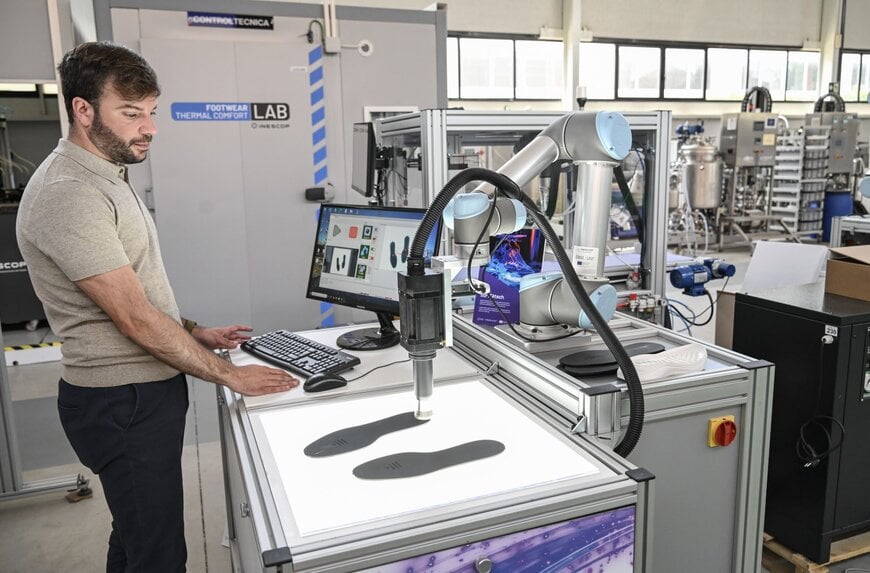

The project is carried out by Inescop, the Footwear Technology Centre, and AIMPLAS, the Plastics Technology Centre, combining expertise in surface treatment technologies and functional coating formulation. Inescop contributes experience in applying advanced surface processes to leather and footwear materials, while AIMPLAS leads the development and characterization of silicon-based coating chemistries.

This collaboration is structured to support technology transfer to industry, ensuring that laboratory-scale results can be scaled to production-relevant conditions.

Industrial validation across multiple material sectors

Several companies are involved in validating the coatings and associated processes under real industrial constraints. Participants include Tempe, part of the Inditex group; footwear manufacturer Pikolinos; textile finishing specialist Acatex; leather processor Pies Cuadrados Leather; and food packaging producer Lisart. Their role covers material supply, process feedback, and functional testing aligned with sector-specific requirements.

This multi-sector validation approach is intended to confirm that the plasma-deposited coatings can be adapted to different substrates and end-use conditions without compromising throughput or quality control.

Alignment with European sustainability and innovation frameworks

PLASRECO is funded under the 2025 call for collaborative R&D projects for technology centres in the Valencian Community, administered by the Valencian Institute of Competitiveness and Innovation (IVACE+i) with support from the European Regional Development Fund (ERDF). The project reflects broader European objectives to reduce hazardous substances in industrial processes while supporting innovation in advanced materials and surface engineering.

By combining atmospheric plasma processing with tailored organosilicon chemistry, PLASRECO illustrates how regulatory change is driving the adoption of cleaner surface treatment technologies in established manufacturing sectors.

www.aimplas.es