www.industryemea.com

15

'26

Written on Modified on

Integrated plastics processing for industrial electronics

Kontron expands injection molding and IMD capabilities at its Leipzig site to strengthen vertically integrated manufacturing for electronics-intensive applications.

www.kontron.com

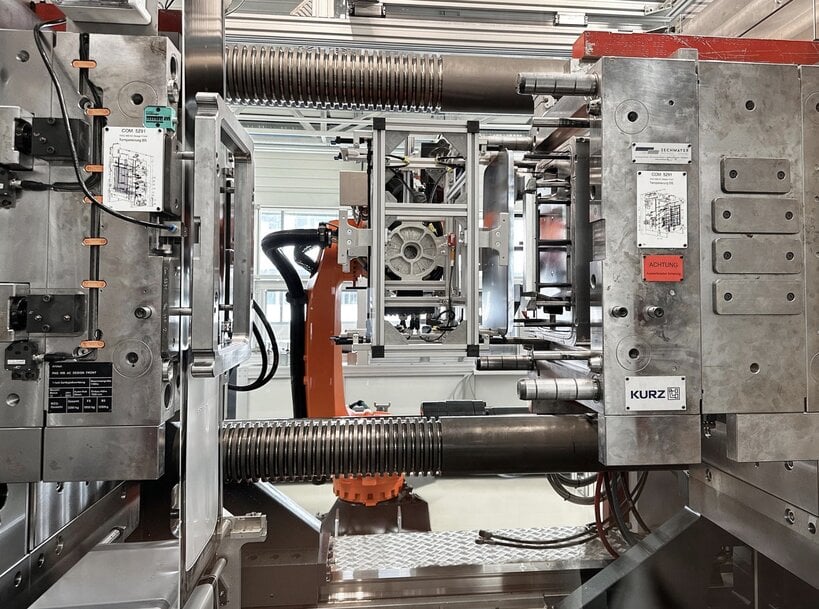

Kontron has expanded its plastics processing capabilities at its Leipzig facility through targeted investments in automated injection molding and in-mold decoration (IMD) technologies. The expansion is carried out under the company’s Electronics² service brand and is intended to support demanding applications in industrial electronics, medical technology, energy systems, and automotive engineering, including electromobility.

Strengthening vertical integration and supply chain resilience

By installing state-of-the-art, highly automated injection molding machines, Kontron eSystems can now manufacture all required plastic components directly at the Leipzig site. This marks a shift from partial external sourcing to full in-house plastics production, reducing dependency on suppliers and improving supply chain resilience across the Kontron Group.

The Leipzig expansion strengthens Kontron’s vertical integration by combining plastics processing with existing electronics manufacturing and testing operations at a single location. This structure enables tighter process control, faster response times, and coordinated quality assurance across mechanical and electronic components.

In-mold decoration for functional and visual components

A central element of the upgrade is the introduction of automated in-mold decoration. The IMD process integrates decorative or functional surface layers directly into the molding process, eliminating secondary finishing steps. This allows the production of plastic parts with consistent surface quality, high durability, and complex visual or tactile features.

Such characteristics are particularly relevant for visible components in medical devices, industrial control systems, and vehicle interiors, where surface quality, chemical resistance, and long-term stability are critical.

Single-site development and production

The Leipzig site is configured to support end-to-end manufacturing, from development and tooling through series production and quality assurance. Fully automated handling and packaging systems, cleanroom-compliant visible-part manufacturing, and centralized material supply are designed to support short cycle times and high variant flexibility.

Production cells incorporate automated part removal and camera-based inspection systems to ensure repeatable quality. A driverless transport system connects process steps across the facility, supporting continuous material flow and reducing manual handling.

Role within the Electronics² network

Electronics² brings together the manufacturing and development capabilities of Kontron, KATEK, and beflex electronic. Within this network, the Leipzig operation functions as a center of excellence for complex plastic visual and functional components, ranging from standard housings to highly customized parts with strict aesthetic and functional requirements.

By integrating plastics processing and electronics assembly under the Electronics² framework, Kontron positions itself to deliver combined mechanical and electronic assemblies with defined interfaces, controlled tolerances, and consistent quality. This approach is intended to support customers seeking compact, reliable, and application-specific solutions in sectors where electronics and mechanical design are increasingly interdependent.

www.kontron.com