www.industryemea.com

30

'26

Written on Modified on

Press Roll Covers with Bio-Based and Recycled Materials

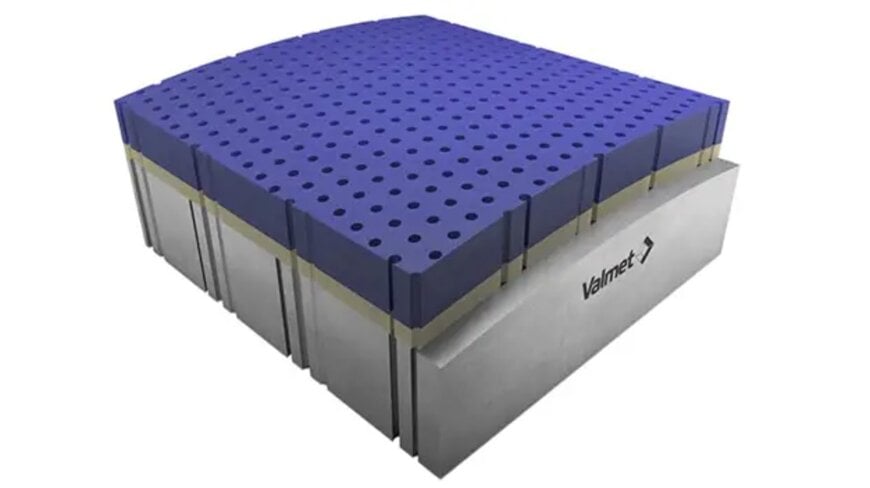

Valmet introduces Bioneer press roll covers, combining circular materials with verified life cycle climate impact data.

www.valmet.com

Valmet has launched Bioneer press roll covers, a new product range manufactured using recycled, renewable, and bio-based raw materials to reduce dependence on fossil resources while maintaining performance in press and suction roll applications.

Circular materials in roll cover design

The Bioneer press roll covers are designed for use in board, paper, tissue, and pulp drying machines. They incorporate recycled, renewable, or bio-based raw materials without compromising key functional requirements such as durability, wear resistance, or dewatering efficiency.

By applying circular material principles at the product level, Valmet addresses growing demand from pulp and paper producers for solutions that support sustainability objectives alongside operational performance.

Application scope and performance requirements

Press and suction roll covers operate under demanding mechanical and thermal conditions. Valmet states that the Bioneer range is engineered to meet the same operational standards as conventional roll covers, ensuring compatibility with existing machine configurations and process conditions.

The covers are intended for a wide range of press sections, enabling adoption across different machine types and grades without changes to operating parameters or maintenance practices.

Life cycle assessment and climate transparency

A defining feature of the Bioneer press roll covers is the inclusion of product-specific life cycle assessment (LCA) data. According to Valmet, these are the first press roll covers to be delivered with verified LCA information, providing transparency on cradle-to-gate climate impacts.

For example, the Valmet Press Roll Cover PF Bioneer demonstrates up to a 12.2% reduction in cradle-to-gate CO₂ emissions compared with standard products. This reduction is achieved through the use of REDcert²-certified renewable and recycled materials applied via a mass balance approach.

Supporting customer sustainability targets

The availability of product-level LCA data enables customers to quantitatively compare the climate impact of different roll cover options. This supports decision-making related to procurement, sustainability reporting, and compliance with corporate or regulatory climate targets.

By providing verified emissions data alongside performance specifications, Valmet positions the Bioneer range as both a technical and environmental solution for press section components.

Industrial context

In the pulp and paper industry, reducing Scope 3 emissions linked to purchased components is becoming increasingly important. Products such as roll covers, which are regularly replaced as part of normal maintenance cycles, offer an opportunity to introduce lower-impact materials without altering core process technology.

The Bioneer press roll covers illustrate how incremental material innovations, combined with transparent life cycle data, can contribute to broader circularity and decarbonization efforts in process industries while maintaining production reliability.

www.valmet.com