www.industryemea.com

11

'26

Written on Modified on

KUKA Showcases Interoperable Mobile Robotics at LogiMAT

Integrated AMRs, six-axis robots and fleet management software enable scalable, interoperable automation for palletizing, transport and mixed-fleet intralogistics operations.

www.kuka.com

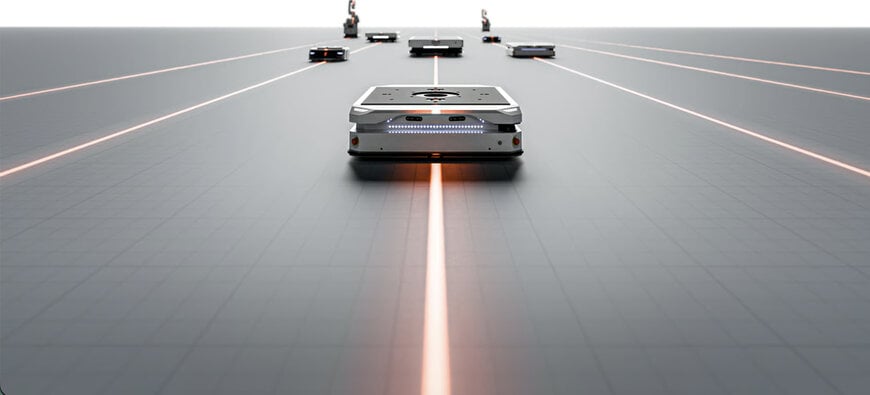

In intralogistics, manufacturing and warehouse automation, seamless integration between autonomous mobile robots (AMRs), stationary robotics and fleet control systems is becoming a decisive factor for scalable automation. At LogiMAT 2026 in Stuttgart (24–26 March), KUKA presents a large-scale interoperability showcase demonstrating how mixed robotic fleets can be orchestrated in real production and logistics environments.

Located in Hall 8, Booth B61, the 600 m² “Interoperability Arena” brings together KUKA and partners including SYNAOS, WIFERION and FPT Robotik to illustrate how mobile robotics, six-axis industrial robots and fleet management software interact in coordinated workflows.

Live integration of AMRs and 6-axis robotics

Within a 75 m² dedicated KUKA area, a KR IONTEC six-axis industrial robot performs palletizing tasks by stacking cartons onto pallets transported by KMP 250P and KMP 600P autonomous mobile platforms. The system, implemented by FPT Robotik, demonstrates synchronized interaction between stationary and mobile robotics.

The setup addresses a common challenge in automated intralogistics: how to combine flexible mobile transport with high-precision industrial manipulation. By integrating AMRs with palletizing robotics, the solution enables modular material flow concepts adaptable to changing production layouts.

Mixed fleet orchestration and real-time control

The central driving zone of the arena demonstrates mixed-fleet operation in live scenarios. Systems from multiple manufacturers operate within a shared environment, coordinated via the SYNAOS Intralogistics Platform.

The software acts as a manufacturer-independent orchestration layer, connecting AMRs, charging systems, fleet control and operational planning. This approach is relevant for operators managing heterogeneous fleets and seeking scalable automation architectures without vendor lock-in.

Wireless charging solutions from WIFERION are also integrated, supporting automated energy management within continuous operations.

Product premiere: KMF 1500P-CB mobile forklift

At LogiMAT 2026, KUKA introduces the KMF 1500P-CB mobile forklift. Designed for automated pallet handling, the AMR-based forklift offers:

- Lifting height up to 3 meters

- Maximum payload of 1,500 kg

- Control via KUKA.AMR OS

- Fleet coordination through KUKA.AMR Fleet

The system is internationally certified and designed for integration into existing logistics environments. With its lifting capabilities, the platform expands KUKA’s AMR portfolio into automated vertical material handling applications.

Digital planning and group presence

KUKA will also present its KUKA.AMR Fleet software for real-time fleet management and monitoring at Booth B61.

Other KUKA Group companies at LogiMAT 2026 include:

Digital planning and group presence

KUKA will also present its KUKA.AMR Fleet software for real-time fleet management and monitoring at Booth B61.

Other KUKA Group companies at LogiMAT 2026 include:

- Swisslog (Hall 1, Booth B41), demonstrating integrated automation and warehouse software solutions

- Visual Components (Hall 8, Booth D80), showcasing 3D simulation tools for validating logistics systems and production processes prior to implementation

By combining robotics, orchestration software and simulation, KUKA demonstrates how interoperable automation systems can increase flexibility and efficiency in intralogistics operations.

www.kuka.com

www.kuka.com