www.industryemea.com

05

'17

Written on Modified on

3-D laser scanning microscope: EPFL Laser microscopy: KEYENCE reinforces 3D vision at EPFL

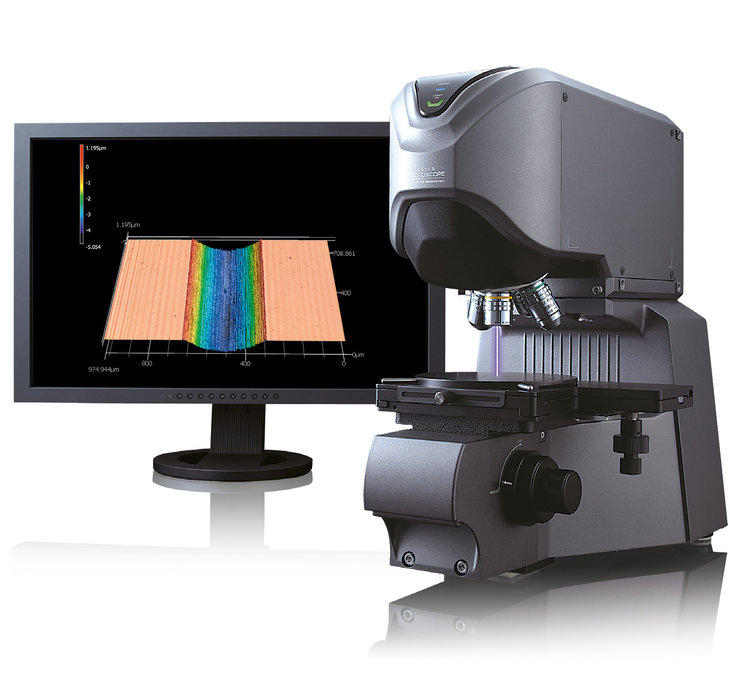

The new VK-X260 3-D laser scanning microscope from KEYENCE, in use in a laboratory at Ecole Polytechnique Fédérale de Lausanne (EPFL), allows researchers to make finer and more rapid surface analyses.

Microscopic surface analysis: essential for researchers, and essential for industry. To briefly elaborate: tribology research for example, (the study of phenomena such as the friction between two materials which are in contact) or the study of corrosion phenomena such as material ageing or wear, allows research laboratories to drive innovation. Industry is fostered by this innovation.

For Dr Stefano Mischler, head of EPFL's Tribology and Interfacial Chemistry Group at EPFL, this means carrying out research projects and/or validating pre-industrial developments. It also consists of running diagnostics of used or corroded mechanical parts to analyse design or ageing problems for the purpose of correcting them. Of course; these are just a few examples.

Microscopy, for "profiling" surfaces

Let's take a simple example: the roughness of a material’s surface affects its appearance, which we can detect visually and/or by touch. But it also impacts the manner by which this material will wear out, due to friction or corrosion, or else its capability to become welded or form a joint with another material or even its ability to retain water, to be painted, etc. In short, the surface profile of a material has important consequences for its endurance, the durability of the mechanical and physical specifications, the potential fragilities of a product made of this material, etc. Hence the need to examine it closely.

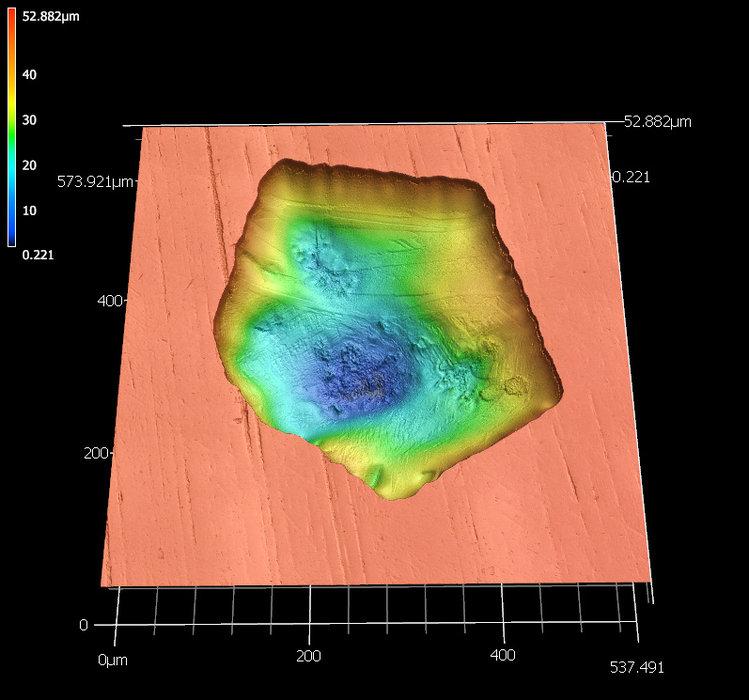

The EPFL laboratories regularly work with industry. Some examples which can be mentioned here are the topography characterisation of used or corroded parts, or the analysis of pits or holes in metallic surfaces damaged by seawater.

Going back as far as the 70s, as Dr Mischler points out, "EPFL's laboratories have acquired a great deal of experience in this area. The targeted range of measurements that we have to perform generally requires accuracies of between 0.1 nm to 10 µm."

The laboratories under his direction are thus equipped with diamond-tipped stylus profilers for contact-type surface tracing and as well as non-contact profilers capable of measurements in the sub-micron range.

“Although a scanning electron microscope (SEM) does not give vertical information (valley depth, and peak height) for characterising a surface profile, an atomic force microscope (AFM) on the other hand is suitable for extremely fine accuracy ranges,” explains Dr Mischler, “it is also too slow for certain applications.” "Switching to a laser scanning microscope is a natural evolution," he concludes.

Technical specifications and performance data

For their new projects, Dr Mischler's teams have to study the microgeometries on the surface of the materials, encompassing their full depth/height. Hence the decision to choose confocal microscopy.

One of the limitations of classic microscopy, in relation to the applications that needed to be addressed here, is that the image can only be sharp in the focal plane of the optical system. The image becomes increasingly blurred as one moves from this plane in or out from the average depth/height of the surface roughness.

In fact, with confocal microscopy, it could be said that the surface under study is scanned using a succession of superimposed focal planes. This technique makes it possible to cover the entire depth/height of the valleys and peaks of the surface microgeometries.

Different solutions were considered, some of which are more specialised than others, explains Dr Mischler. Furthermore, the quality of the instrument, its ease-of-use and the accessibility of information were decisive factors determining the choice, which was finally made in favour of the 3-D confocal laser scanning microscope from KEYENCE. In brief, its specifications are as follows: vertical levels = 14 million; magnification = 28800x; display resolution = 0.5 nm; lighting of the sample under analysis = white light and 408 nm laser.

Ease-of-use, flexibility

To summarise, "we want to be able to combine the quantitative and qualitative measurements of the valleys and peaks on the surfaces being studied or analysed," says Dr Mischler. Then he adds, "topographical display in 3-D images makes it possible to very rapidly and easily obtain information which can be directly utilized in the results of the study or analysis."

Whereas other solutions require purchasing two separate software programs, one to perform the measurements and another to process the data, one of the main advantages of the KEYENCE solution is that it integrates these two tools in the same software package," points out Dr Mischler.

By offering a unique combination of accuracy, ease-of-use and measurement speed, the VK microscope has shown itself to be the most powerful system technically. However, if needed, there is nothing to prevent exporting the measurement data to ultra-fine analysis tools.

"The KEYENCE software tool is really user-friendly," concludes Dr Mischler. "After a quick presentation, the students quickly became familiar with the system and in a few days they were able to make good use of the instrument's capabilities and produce very pertinent results. It's evident that the KEYENCE system was designed to be used intensively. It answers perfectly to the production engineers’ desire for immediacy without frustrating the research engineers’ needs of in terms of the quality and accuracy they demand.”

Responsiveness and support

At EPFL, "university time" and "industrial time" meet and intermix, driven by necessity. In practice, certain projects are financed within the framework of topographical surface characterisation and innovation projects for industry (watch-making... biomedical... materials... aeronautics etc.).

In fact, as Adrien Peignault from KEYENCE explains, "the 3-D laser scanning microscope is a system that was initially designed with the productivity of industrial sites in mind. Although the requests from Dr Mischler and his students are sometimes very intricate, we try to respond as quickly as possible, as we do for all our industrial clients." And he adds, "in any case, EPFL itself has always paid attention to giving good service to its own partners on certain projects, including when they have the constraints of an industrial company."

École Polytechnique Fédérale de Lausanne (EPFL) is one of the two federal polytechnic schools in Switzerland. Awarded the status of national school since 1969, the young engineering school has grown on many different levels and has now become one of the most famous science and technology institutions in Europe. Just like its sister school in Zürich, the ETHZ it is founded on three basic missions, education, research and technology transfer. Associated with several specialised research institutes, the two polytechnic schools form the EPF domain which is directly under the federal Department of the Economy, Education and Research (DEFR).

EPFL is located in Lausanne, Switzerland on the borders of the largest lake in Europe, Lake Geneva, and at the foot of the Alps and Mont Blanc. The main campus has a population of nearly 14,000, of which 10,000 are students. With its dynamism and vibrant student community, EPFL has managed to create a unique spirit of curiosity and simplicity. The daily interchange between students, researchers and entrepreneurs present on campus, encourage the emergence of new scientific, technological and architectural projects.