www.industryemea.com

05

'18

Written on Modified on

Safe as well as efficient

The HAIMER Safe-Lock™ pull out protection system is becoming the industry standard.

By now Safe-Lock™ has become a de-facto standard in the area of tool holding for milling operations. Within the last ten years, since the introduction of the Safe-Lock™ system, it has been confirmed over and over that this method of clamping the tool is often clearly superior to conventional Milling Chucks and Weldon shanked tool holders. This is proven by a large number of license partners, some of which rank amongst the world’s leading cutting tool and tool holder manufactures - for example Walter, Widia, Sandvik Coromant, Seco Tools, Sumitomo, Kennametal, Helical, Emuge Franken, Data Flute, Niagara, OSG and Mapal. In 2017, Iscar and Ingersoll also decided to offer tools with the Safe-Lock™ shank. Furthermore, the shrink, collet and hydraulic chuck Safe-Lock™ tool holder portfolio has become much larger within the last few years. In addition to the Safe-Lock™ hydraulic chucks from Kennametal, Mapal is already working to introduce its hydraulic chuck offering with Safe-Lock™ to the market.

Andreas Haimer, Managing Director of HAIMER GmbH, explains: “We are proud that our Safe-Lock™ pull out protection system has established itself as the new standard in the heavy duty and rough milling industry and is also becoming more and more important in other areas such as trochoidal milling. We are also very happy about our new license partners, who help expand the Safe-Lock™ portfolio and also make it available for more end-users.”

Successful in the Aerospace Industry

Safe-Lock™ has emerged from the requirements of heavy-duty machining, which is a daily challenge in the aerospace and energy producing industries. Innovative materials such as various titanium alloys are not only light, but also very rigid, corrosion resistant and difficult to machine. This doesn’t only affect the machine concepts and processes, but also the cutting tools and tool holders that are being used.

Many workpieces are made from a solid block – during this milling process up to 90% of the material is being removed. In order to optimize the process economically as well as qualitatively and in order to achieve a high metal removal rate, high torques and feed rates with low rpms are chosen. But during this High Performance Cutting operation (HPC), high pulling forces occur. In combination with high cutting forces and aggressive feed rates, a flexing movement of the tool in the tool holder is created which in the end increases the risk of tool pull out. This especially affects all the tool holder designs which provide accurate clamping and a high run-out accuracy, like for example shrink, hydraulic or milling chucks.

As a consequence Safe-Lock™ is now widespread within the aerospace industry. Alexander Steurer, Senior Manager NC - Programming Stator Components at MTU Aero Engines in Munich, explains the decision to use the HAIMER system: “Through the introduction of Safe-Lock™ and the shrinking technology from HAIMER, we can guarantee process reliability even with milling challenging high temperature materials. This is a prerequisite to guarantee smooth processing during manufacturing of frames and castings, given our high degree of automation.“ The combination of pull-out protection and highest concentricity of the Safe-Lock™ system leads to low vibration and as a result, a very stable machining process. Due to the increased cutting depths and feeds, the metal removal rate can be increased significantly. And thanks to the improved runout accuracy of HAIMER shrink fit chucks, tool life is improved by up to 50%.

The benefits of less than 3 µm runout, that the symmetrical Safe-Lock™ design provides, coupled with optimum balance and the possibility for easy length presetting were substantial reasons for MTU to switch to the HAIMER system instead of continuing to use Whistle Notch or Weldon tooling systems. While these other systems do in fact prevent tool pull out, both are unsymmetrical by design, hence providing insufficient runout and balance accuracy.

Higher Productivity with Safe-Lock™

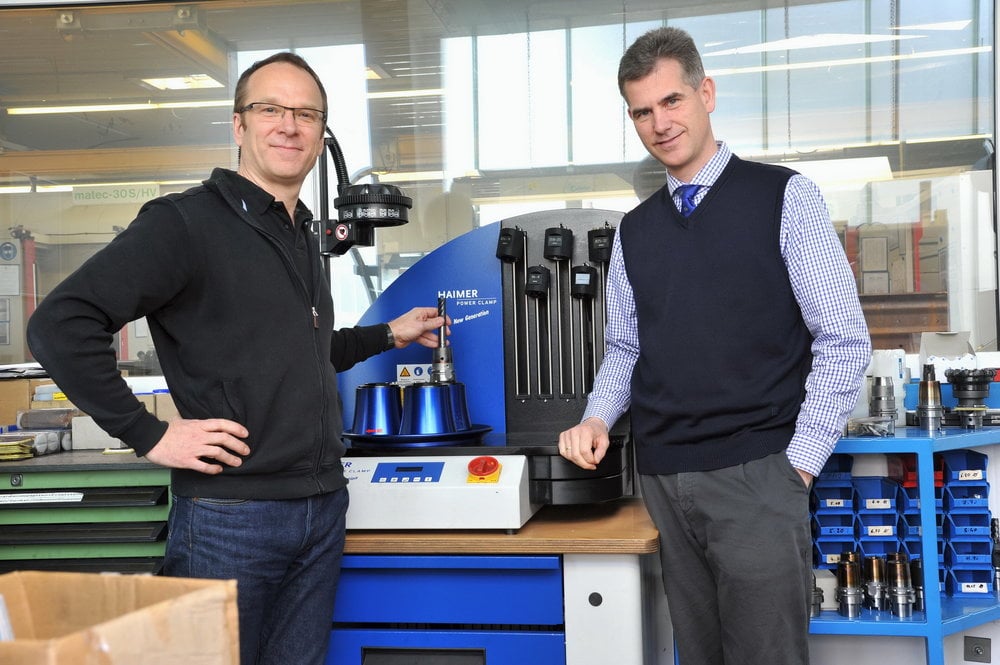

However, Safe-Lock™ has not only found enthusiastic followers in the aerospace industry. Working at Glätzer, Daniel Rautenbach knows how fiercely competitive and thorough the automotive industry can be. The Managing Director of the CNC-Machining Specialists located in Solingen explains: “Perfect quality and delivery reliability are the basic requirements in order to quote in our industry. Pricing is highly competitive.” Therefore, in his business, the difference between profit and loss comes down to process efficiency. Hence quality without compromise is a must.

Through one of the biggest projects in this area Ingo Schulten, Operation Manager, became aware of the HAIMER Safe-Lock™ pull out protection system and started using it in the middle of 2013. The specific application was a part for a pneumatically operated truck disk-brake which consisted of spheroidal-graphite cast iron, Type EN-GJS-800-2. In order to mill concave contours the contact between cutting tool and the work piece isn’t just punctual, but it actually covers between 30 or 40 percent of the tool. Ingo Schulten explains: “The extremely high engagement and cutting forces cause the tool to want to pull out from the holder.” The utilized Weldon Chucks ensured that the cutting tool stayed in the holder, but the side lock screw prevented the tool from achieving good runout accuracy. According to Schulten “the tool life was very unstable which even led to tool breakage”.

The milling tests with Safe-Lock™ convinced him and the other employees at Glätzer. “To me the switch to Safe-Lock™ seemed obvious, like using an electric starter instead of a crank to start a car” Schulten explained enthusiastically. “The cutting data improved significantly. The tool life increased by 40% consistently.”

Benefits of High Speed Cutting

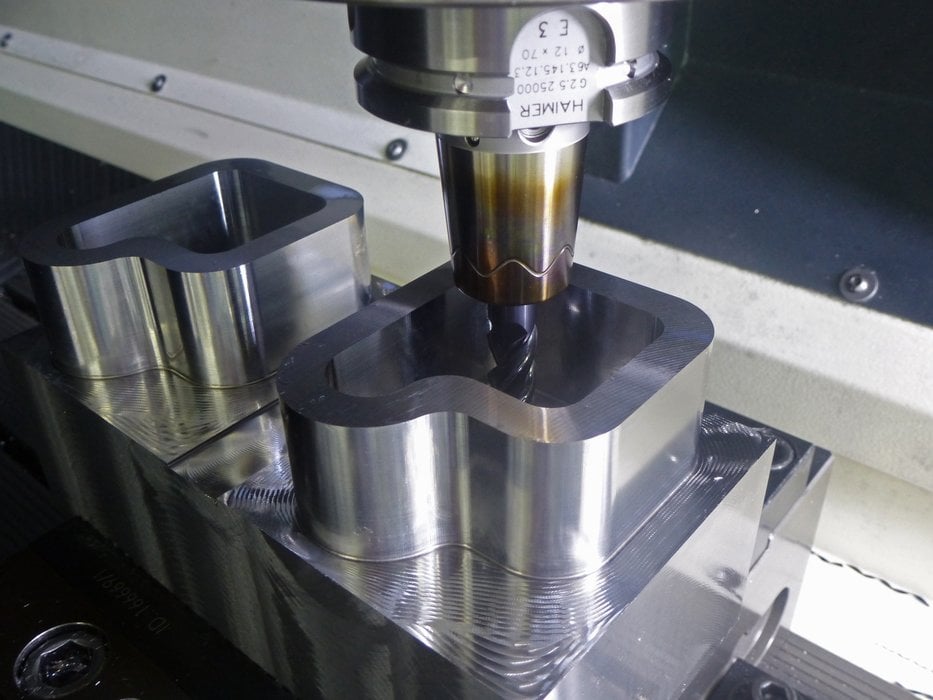

Safe-Lock™ is also becoming increasingly popular in other industries and during HSC machining with high-helix end mills as well as in trochoidal milling. During trochoidal milling operations, where the cutting speed and axial depth of cut can be increased through software support, the productivity is significantly improved. Thus milling operations are carried out three times faster with deeper depths pf cut, even when it comes to hard and difficult to machine materials.

However this also increases the danger of tool pull out. Even though only a thin chip is usually removed during trochoidal milling operations, often the entire length of the cutting tool edge is used during the process. This results in higher axial forces which force the operator to pay attention to safe cutting tool clamping. A shrink fit chuck with Safe-Lock™ is the ideal solution since it offers more security than the Weldon system, is easier to install and can be clamped very precisely. The ideal balancing and runout characteristics of the shrinking technology in combination with the clamping safety of the Safe-Lock™ system permit the possibility of greater productivity achieved through faster permissible speeds and increased tool life all with complete tool security assurance.

INFO BOX

Safe and Efficient Tool Clamping

The Safe-Lock™ principle can be explained as follows: spiral-shaped grooves are ground into the cutting tool shank, which have the same angle like that in the tool. In combination with special EDM form closed drive keys in the tool holder (shrink fit chucks, collet chucks or also hydraulic chucks) the grooves prevent the cutting tool from twisting or being pulled out of the chuck during extreme machining, which causes very high costs when producing expensive work pieces. The combination of pull out protection and high runout accuracy leads to less vibrations and very efficient metal removal rates. With this it is possible to increase the metal removal rates significantly by increasing the cutting depth and the feeds. In addition tool wear will be reduced.

In 2017 Iscar and Ingersoll received a license for cutting tools. Through the large offering of tool manufacturers Safe-Lock™ has become a standard for many industries.

Picture: Haimer

MTU Aero Engines manages challenging roughing applications for the military turboprop engine TP400-D6 with Haimer Safe-Lock. MTU is responsible for the TP400-D6’s intermediate-pressure compressor, intermediate-pressure turbine and intermediate-pressure shaft and has a stake in the engine control unit. Furthermore, final assembly of all TP400-D6 production engines takes place at MTU Aero Engines in Munich.

Picture: MTU Aero Engines

Glätzer CEO Daniel Rautenbach (on the right) and Manager Ingo Schulten are continuously extending the use of HAIMER shrinking technology, with and without Safe- Lock™: “To us the switch to Safe-Lock™ seemed obvious, like using an electric starter instead of a crank to start a car.”

Picture: Haimer

Trochoidal milling makes the milling operation three times faster and deeper, even in hard materials like stainless steel or titanium. Ideal tools for machining are the HAIMER Power Mill end mills with Safe-Lock™-chuck.

Picture: Haimer