www.industryemea.com

02

'10

Written on Modified on

Uniquely robust UNICASE design

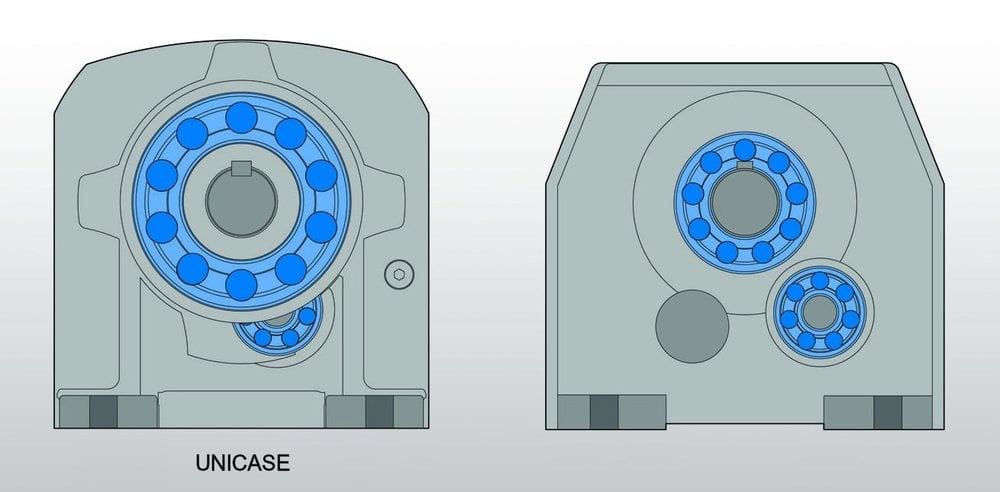

NORD’s unicase design for geared motors integrates all bearing seats into a single-piece casting, thus eliminating all sealing surfaces that could deflect under the effect of torque or radial forces.

The finishing of this unicase is carried out with in unique jig, on state-of -the-art CNC machines. The unicase concept features highest levels of precision, rigidity and strength. There are no dividing seams between the drive and the gear unit housing which are subjected to transverse forces or torque. The unicase principle allows the shaft axes to be staggered, resulting in a more compact design which allows the use of larger roller bearings to guarantee a long operating life.

Unicase housings provide optimum sealing, quiet running, high torque capacity, increased lubricant life, maximised operating life of bearings and gears, high reliability, and many other adavtanges. They are available in 6 installation configurations, made mirror-image installation possible, and have the same housing size, or installation dimensions for all ratios (2 and 3 stage).

Image: UNICASE housings compared to conventional design.

Unicase housings provide optimum sealing, quiet running, high torque capacity, increased lubricant life, maximised operating life of bearings and gears, high reliability, and many other adavtanges. They are available in 6 installation configurations, made mirror-image installation possible, and have the same housing size, or installation dimensions for all ratios (2 and 3 stage).

Image: UNICASE housings compared to conventional design.