Nelson automotive rebrands as Avistud

Global automotive stud welding leader Nelson Automotive has announced a complete rebrand of its business to customers, stakeholders and industry peers.

The newly launched brand, AVISTUD, reflects the total separation of the Nelson Automotive business from the brand of its former industrial parent Nelson Stud Welding. Nelson Automotive was initially created as a standalone automotive company following the sale of Nelson Stud Welding from Doncasters to Stanley Black & Decker in April 2018.

AVISTUD, whose name represents the Automotive, Versatile and Innovative stud welding that the firm brings to the industry, will focus solely on providing high-tech products to car manufacturers and their suppliers. In December 2018, the company announced a major new deal to supply Daimler AG with innovative technology equipment for the production of Mercedes Benz C-class and S-class ranges.

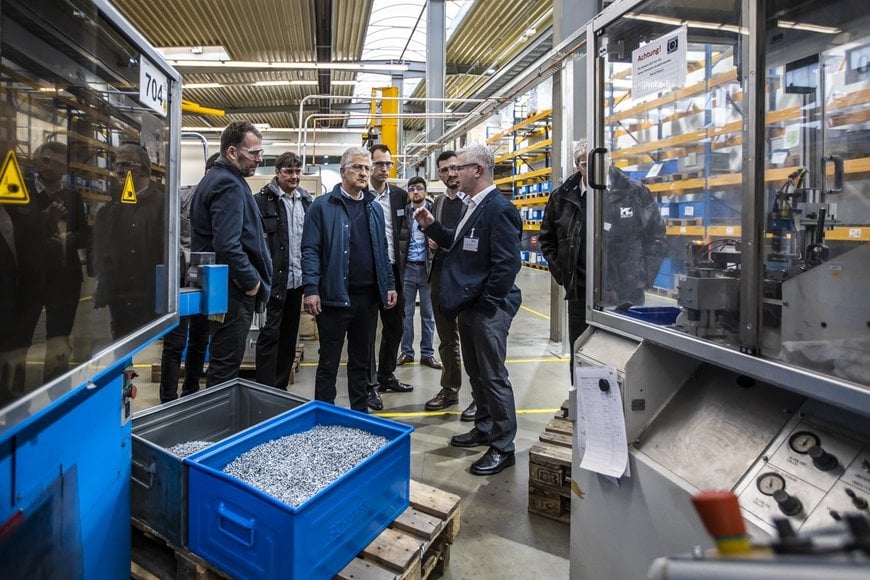

Henning Stams, chief executive of AVISTUD, said: “The automotive industry is demanding more speed and flexibility from its manufacturing processes than ever before. We have adapted our business to meet the automotive sector’s requirement for more lightweight, high-strength materials, electric vehicles and faster manufacturing processes.”

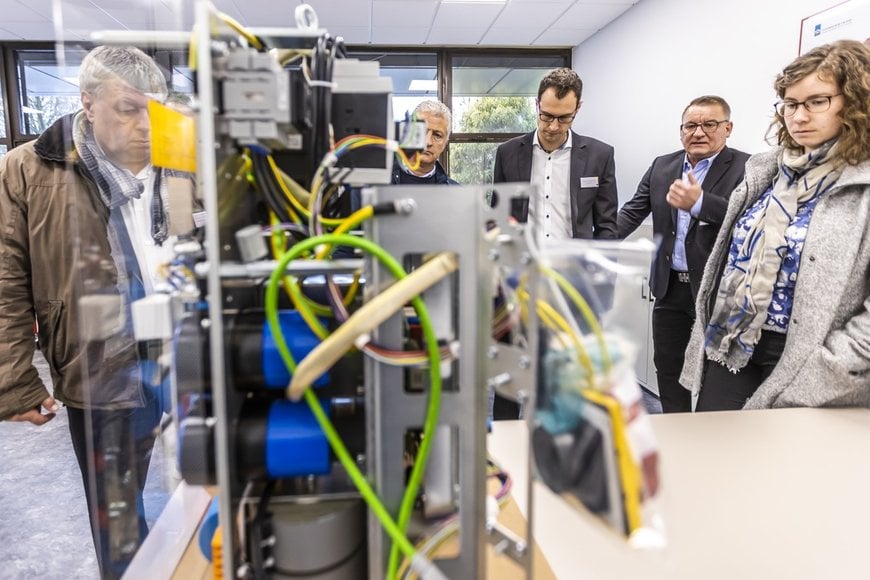

Eduard Kirchner, head of AVISTUD’s engineering group, added: “We are the leading technological innovator in stud welding with a strong team of experienced engineers. Under our new brand of AVISTUD, we will be one hundred per cent focused on serving the global automotive market, where customers already trust our innovation and versatility to help deliver the vehicles of the future.”

AVISTUD is at the forefront of innovation in the sector. For example, its SPEEDPORT feeding system enables a single unit to weld more than 40,000 studs in a day. The company also offers an extensive range of manual and automatic systems, as well as robotic weld heads for high production environments.

With its global physical presence in many countries in Asia, Europe and the Americas, products will continue to be developed and manufactured in Germany, where its dedicated team of more than 100 employees is focused on creating the next generation of stud welding systems, pushing the boundaries of speed, performance and durability.

“Our team is committed to researching, developing, and bringing to market the best new processes for our clients - whether that be for systems for new production facilities, or upgrades to existing plants. We look forward to announcing the future investments and developments already in the pipeline.” concluded Stams.

For more information on AVISTUD, please see https://www.avistud.com