www.industryemea.com

02

'19

Written on Modified on

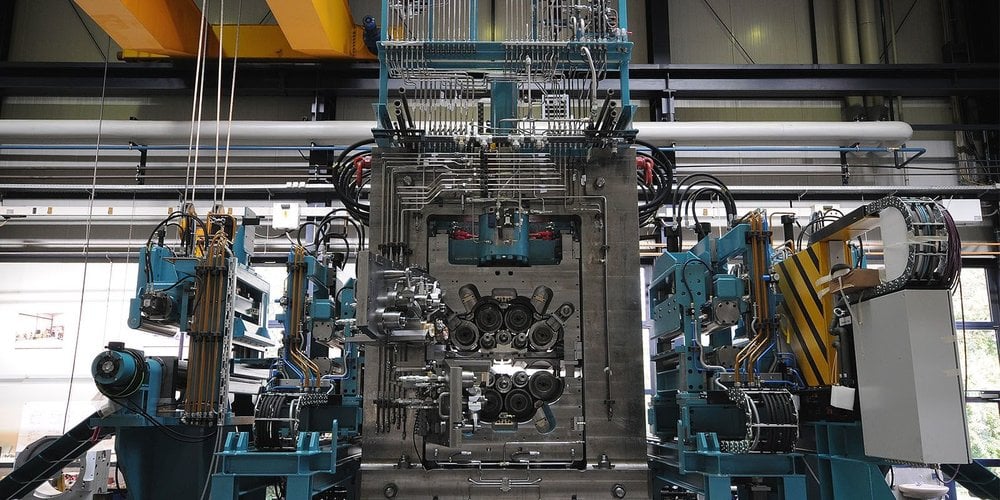

Two 20-high, copper cold-finishing mills ordered from Danieli

Ningbo Powerway Alloy Material Co., China, chooses Danieli Fröhling foil-rolling technology for its third-phase expansion project.

Manufacturing the core equipment in Meinerzhagen at Danieli Germany workshops and based on Danieli Fröhling technology, the twin-housing type mills will be equipped with the patented intermediate-roll double bending system for improved strip flatness and direct hydraulic roll-gap control for high-precision thickness performance. The mills will be capable of using a large range of work-roll diameters, from 37 to 80 mm, in order to achieve efficient and economic rolling performance.

The final applications of the high-performance copper-alloy strip produced by Ningbo Powerway Alloy Material Co. will be mainly used for aerospace, high-speed trains, solar energy, telecommunication and electronic industry.

Plant startup is expected by the last quarter of 2020.

www.danieli.com