www.industryemea.com

16

'19

Written on Modified on

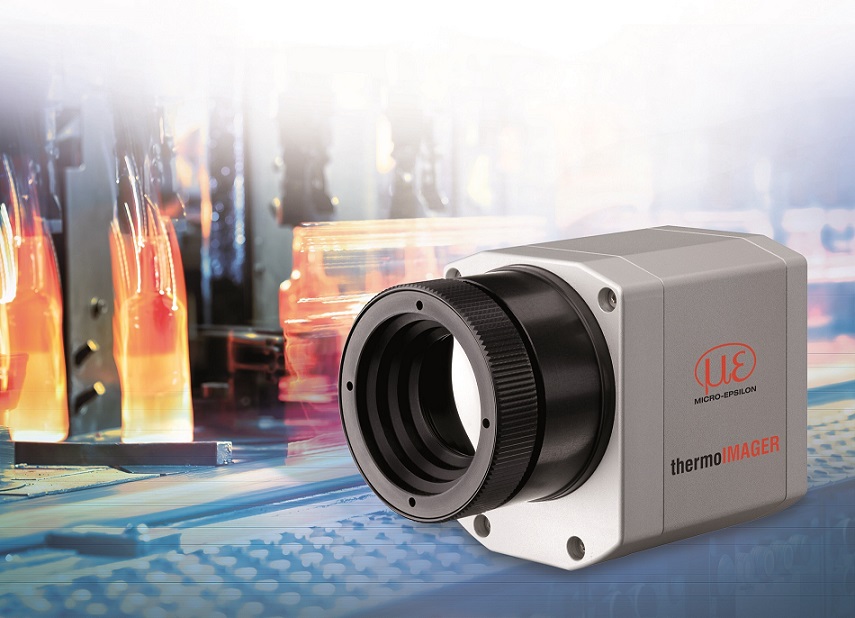

Precise temperature measurement in industrial processes

Depending on the model, the thermoIMAGER TIM infrared cameras are suitable for inline real-time monitoring in the production line and for mobile use.

Temperature measurement in glass production

The thermoIMAGER G7 is an industrial thermal imaging camera specially designed for applications in the glass industry. The spectral range of 7.9 µm enables reliable measurements even on thin glass sheets without unwanted transmission loss. The software offers a line scan camera feature which detects the temperature cross profile of moved objects line by line. This enables monitoring and, if necessary, readjustment of hot and cold zones.

Microscope lens for temperature monitoring of ultra-small objects

The microscope lens from Micro-Epsilon inspects and continuously monitors the temperature of ultra-small parts. This enables macro shootings with a spatial resolution up to 28 µm. The microscope lens is available for the thermoIMAGER TIM 450 and 640 cameras.

Infrared camera for high temperature applications

The short-wave thermoIMAGER TIM M05 and TIM M1 thermal imaging cameras are particularly suitable for measurements performed onto hot metals, graphite and ceramics. These cameras are used in different situations such as metal hardening and forming processes.

Unique selling points include a continuous temperature measuring range from 450 °C to 2,000 °C, frame rates up to 1 kHz and different resolution/image frequency modes. With a water-cooled protection housing, high ambient temperatures are not an issue.

www.micro-epsilon.com