www.industryemea.com

24

'11

Written on Modified on

Getting the latch and hinge specification right

Southco discusses how the latching and hinging solution is integral to the success of an enclosure design

Whilst the specification of the correct access hardware for an enclosure need not be overly complicated, it can never be a case of ‘one size fits all’. The latching and hinging solution is integral to the success of an enclosure design and should, therefore, be integral to the design process.

As the global leader in engineered enclosure access hardware, Southco offers a multitude of latching and hinging solutions. To help select the best options for any application, its design engineers have identified some key considerations for access hardware in enclosure applications, all of which impact enclosure performance, security and economy.

The first step to selecting the right solution is to identify the primary performance characteristics for the individual application and then match these with the appropriate existing access hardware option, or use the application design considerations as the input parameters for a new access hardware custom design.

For example, are you looking for quick, simple, economical latching alternatives? Do you need a degree of flexibility to compensate for variations in material dimensions or changing grip dimensions? If the answer to those questions is ‘yes’, cam latches can be a cost-effective answer.

On the other hand, the application may require gaskets or environmental sealing to satisfy specific industry standards or to provide general protection against dust, rain of electromagnetic interference (EMI) or radio frequency interference (RFI). Such applications may be best suited to compression latches with the specific style chosen based on the enclosure design and installation environment. Other factors that could steer you towards compression latches are applications subject to vibration or rattle.

If the convenience of a ‘slam-shut’ operation, with quick and easy enclosure access, is desirable for user-friendly operation, the choice will move towards a push-to-close latch style, either locking or non-locking. If the enclosure has co-planar panels and you need to compensate for some misalignment in the mating of the two panels, a draw latch can actually draw two panels - or a panel and frame – together in the same plane. Different lever-action or rotary-action styles provide varying amounts of draw and can provide relatively high maximum working loads.

In some applications, where enclosure doors cover a large span, a multi-point latching solution can include compression, locking or hidden actuator features for added performance and security.

With a growing need to monitor access to enclosure applications, electronic access technology has moved inside and is fast becoming the preferred method of access management for a vast array of product enclosures. Well-designed electronic access solutions offer heightened security, improved functionality, better traceability and more convenience to a range of exponentially growing applications. Various industry-electronic latching styles available include push-to-close, swinghandle or rotary action. Each latch offers flexibility in access control, such as key pad, card swipe, key fob, biometric reader, or mobile phone.

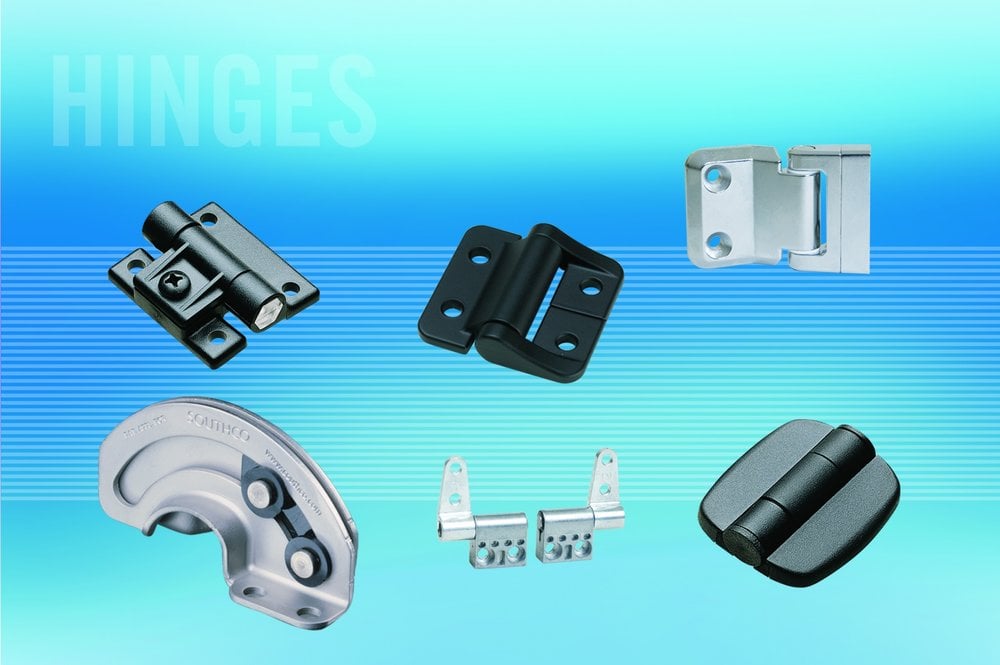

A similar process is applied to the selection of the hinge, of which there are three major hinge installations: external, embedded or concealed.

If you need to maximize available space inside the enclosure, wish to attach or remove a door without tools, or are looking for a drop-in replacement that meets most standard panel preps, an external hinge might well be the most appropriate option. Mounting options are available to suit most door and frame configurations, and provide easy installation. To suit specific requirements of individual applications, customised solutions are the answer.

For cabinets which require the hinge to be invisible when the door is closed, or where hinges need to be inside the enclosure, concealed hinges that combine hidden mounting with simple installation offer both security and the ability to achieve a sleeker look to the enclosure.

For designs that need to seamlessly integrate position control features, embedded hinges can be designed-in to become an integral part of any application. These hinges allow for a variety of positioning control options while fitting into an existing envelope for both small and large applications. When the requirement for motion management goes beyond a simple rotational motion, such as the need for torque, detent, bi-stable or counterbalance features, custom engineered positioning mechanisms can provide new levels of refinement and functionality to meet any motion management challenge. By having the early involvement of the right access hardware specialists in the design process, costly mistakes can be avoided and the best solution for the application identified and incorporated from the outset to ensure that the integrity of the overall finished design is preserved.

Whilst the choice may appear to be endless, to help simplify the process, Southco has created an enclosure design guide which enables you to evaluate, compare and select the best latch, hinge, gasket and rack-attach solutions for your application. To get this free guide please visit our homepage under www.southco.com

or contact us through This email address is being protected from spambots. You need JavaScript enabled to view it.

As the global leader in engineered enclosure access hardware, Southco offers a multitude of latching and hinging solutions. To help select the best options for any application, its design engineers have identified some key considerations for access hardware in enclosure applications, all of which impact enclosure performance, security and economy.

The first step to selecting the right solution is to identify the primary performance characteristics for the individual application and then match these with the appropriate existing access hardware option, or use the application design considerations as the input parameters for a new access hardware custom design.

For example, are you looking for quick, simple, economical latching alternatives? Do you need a degree of flexibility to compensate for variations in material dimensions or changing grip dimensions? If the answer to those questions is ‘yes’, cam latches can be a cost-effective answer.

On the other hand, the application may require gaskets or environmental sealing to satisfy specific industry standards or to provide general protection against dust, rain of electromagnetic interference (EMI) or radio frequency interference (RFI). Such applications may be best suited to compression latches with the specific style chosen based on the enclosure design and installation environment. Other factors that could steer you towards compression latches are applications subject to vibration or rattle.

If the convenience of a ‘slam-shut’ operation, with quick and easy enclosure access, is desirable for user-friendly operation, the choice will move towards a push-to-close latch style, either locking or non-locking. If the enclosure has co-planar panels and you need to compensate for some misalignment in the mating of the two panels, a draw latch can actually draw two panels - or a panel and frame – together in the same plane. Different lever-action or rotary-action styles provide varying amounts of draw and can provide relatively high maximum working loads.

In some applications, where enclosure doors cover a large span, a multi-point latching solution can include compression, locking or hidden actuator features for added performance and security.

With a growing need to monitor access to enclosure applications, electronic access technology has moved inside and is fast becoming the preferred method of access management for a vast array of product enclosures. Well-designed electronic access solutions offer heightened security, improved functionality, better traceability and more convenience to a range of exponentially growing applications. Various industry-electronic latching styles available include push-to-close, swinghandle or rotary action. Each latch offers flexibility in access control, such as key pad, card swipe, key fob, biometric reader, or mobile phone.

A similar process is applied to the selection of the hinge, of which there are three major hinge installations: external, embedded or concealed.

If you need to maximize available space inside the enclosure, wish to attach or remove a door without tools, or are looking for a drop-in replacement that meets most standard panel preps, an external hinge might well be the most appropriate option. Mounting options are available to suit most door and frame configurations, and provide easy installation. To suit specific requirements of individual applications, customised solutions are the answer.

For cabinets which require the hinge to be invisible when the door is closed, or where hinges need to be inside the enclosure, concealed hinges that combine hidden mounting with simple installation offer both security and the ability to achieve a sleeker look to the enclosure.

For designs that need to seamlessly integrate position control features, embedded hinges can be designed-in to become an integral part of any application. These hinges allow for a variety of positioning control options while fitting into an existing envelope for both small and large applications. When the requirement for motion management goes beyond a simple rotational motion, such as the need for torque, detent, bi-stable or counterbalance features, custom engineered positioning mechanisms can provide new levels of refinement and functionality to meet any motion management challenge. By having the early involvement of the right access hardware specialists in the design process, costly mistakes can be avoided and the best solution for the application identified and incorporated from the outset to ensure that the integrity of the overall finished design is preserved.

Whilst the choice may appear to be endless, to help simplify the process, Southco has created an enclosure design guide which enables you to evaluate, compare and select the best latch, hinge, gasket and rack-attach solutions for your application. To get this free guide please visit our homepage under www.southco.com

or contact us through This email address is being protected from spambots. You need JavaScript enabled to view it.