www.industryemea.com

13

'19

Written on Modified on

LNS ‘Blasts’ Away Coolant Challenges With New Business Introduction at EMO

At the EMO exhibition in Hannover, the world leader in bar feeding, air filtration, coolant management and chip management systems for machine tools, the LNS Group will be introducing its new Chipblaster product line. The LNS Group acquired Chipblaster Inc. in October 2018 and the integration of the Chipblaster business will provide the industry leading coolant management systems with a direct route to market in Europe and worldwide markets via the LNS Group sales and service network. The first opportunity for the European market to view the Chipblaster flagship products will be on Stand D16 in Hall 17 at the EMO Fair from 16th to 21st September.

LNS Chipblaster JV-40 with chiller and cyclonic filtration

Commenting upon the acquisition, LNS Group CEO Gilbert Lile says: “Chipblaster is a market leader in the U.S. high-pressure coolant industry and is a natural fit into our machine tool peripheral product portfolio. At LNS, we plan to leverage our global sales and service network to sell Chipblaster’s technologically advanced products on a worldwide basis. A common thread running through both companies is the goal of helping manufacturers optimize the efficiency of their machine tools to improve performance, productivity and profitability.”

With over 1000 employees, a global sales and service network and nine production sites on three continents, the LNS Group will leverage its worldwide presence to introduce the countless benefits of the proven Chipblaster product range. A key opportunity to introduce its benefits to the LNS Group network of customers in Europe will be at the EMO exhibition where the LNS Group will demonstrate a complete range of LNS innovations alongside the newly integrated Chipblaster products. Across the Chipblaster range, the benefits for manufacturers are apparent. The Chipblaster high-pressure coolant systems deliver an automatically variable volume of high-pressure coolant to improve machining performance, tool life, chip evacuation, machine tool efficiency and energy reduction thanks to the Automatic Variable Volume system.

For uncompromising control of the machine tool environment, the Chipchiller incorporates a built-in circulation pump, signal and filter alarm circuits and complete ambient temperature tracking. This ensures that machine tools retain their optimal operating temperature to minimise thermal drift and the impact of temperature deviations, meaning your machine tool retains its optimal precision level regardless of the machine shop environment.

Easily integrated into any sump or machine tool, the Skimblaster system can also work in synergy with the Chipblaster high pressure coolant system. With three skimming depths, two separate tramp oil collection chambers and a variable on/off timer, the Skimblaster is the ideal partner to clean up any machine tool.

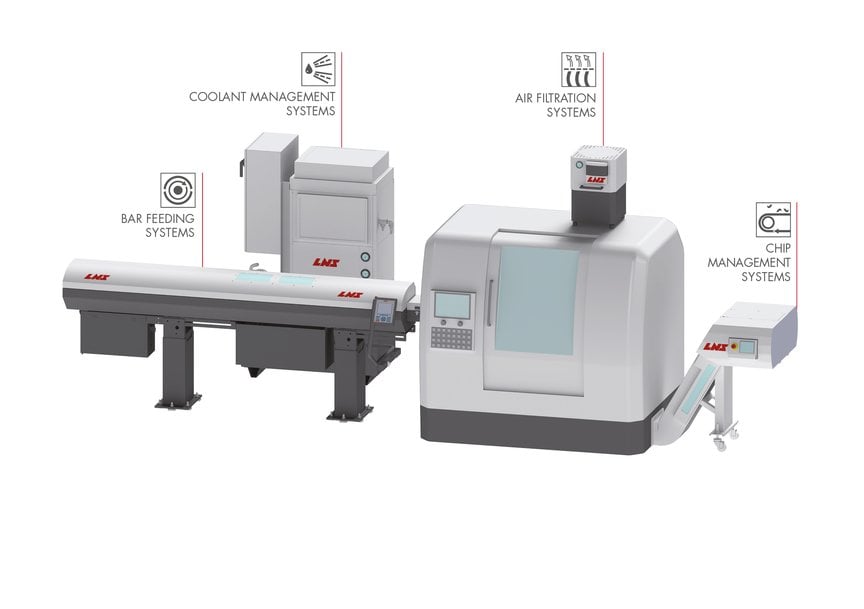

LNS product range for machine-tools

The benefit of using the LNS Group as your partner for the complete management of machine tool peripherals is that with just a single contact with one of LNS’ highly skilled team, all of your needs will be met. From technical advice, solutions and purchases through to service and technical support, the team at the LNS Group will accommodate all your machine tool peripheral needs.

Please visit our stand (D16 in Hall 17) at EMO to see the expanded product portfolio as well as a completely redesigned bar feeder system.