www.industryemea.com

18

'11

Written on Modified on

TSUBAKI / KABELSCHLEPP present the optimized plastic cable carrier TKR0200 (20 mm pitch)

Extremely quiet and resistant to abrasion due to the new design

KABELSCHLEPP, A member of the TSUBAKI GROUP is pleased to announce the remodeled TKR0200 plastic cable carrier.

The TKR plastic cable carrier, renowned for their low-noise design and low dust generation, ensure clean and quiet operation thanks to their unique bending design incorporating, a short pitch and flexible plastic as well as the adoption of an extremely slippery material offering excellent wear-resistance. Since its launch in 2006, the model TKR0200 has proved to be extremely popular as a result of its adoption in many growing industries. For example, this product is used in semiconductor/LCD fabrication equipment; equipment for manufacturing solar panels/solar cells and lithium-ion batteries; precision machinery; and a variety of other applications requiring low-noise operation and low dust generation.

The model TKR0200 has been redesigned for greater protection and easier handling of hoses and cables. In addition, it generates less noise and dust than does the previous generation of the cable carrier.

Eco Link Mark

Note: This new product meets our voluntary eco assessment criteria.

The TKR plastic cable carrier, renowned for their low-noise design and low dust generation, ensure clean and quiet operation thanks to their unique bending design incorporating, a short pitch and flexible plastic as well as the adoption of an extremely slippery material offering excellent wear-resistance. Since its launch in 2006, the model TKR0200 has proved to be extremely popular as a result of its adoption in many growing industries. For example, this product is used in semiconductor/LCD fabrication equipment; equipment for manufacturing solar panels/solar cells and lithium-ion batteries; precision machinery; and a variety of other applications requiring low-noise operation and low dust generation.

The model TKR0200 has been redesigned for greater protection and easier handling of hoses and cables. In addition, it generates less noise and dust than does the previous generation of the cable carrier.

Eco Link Mark

Note: This new product meets our voluntary eco assessment criteria.

Features

1. Reduced noise in operation

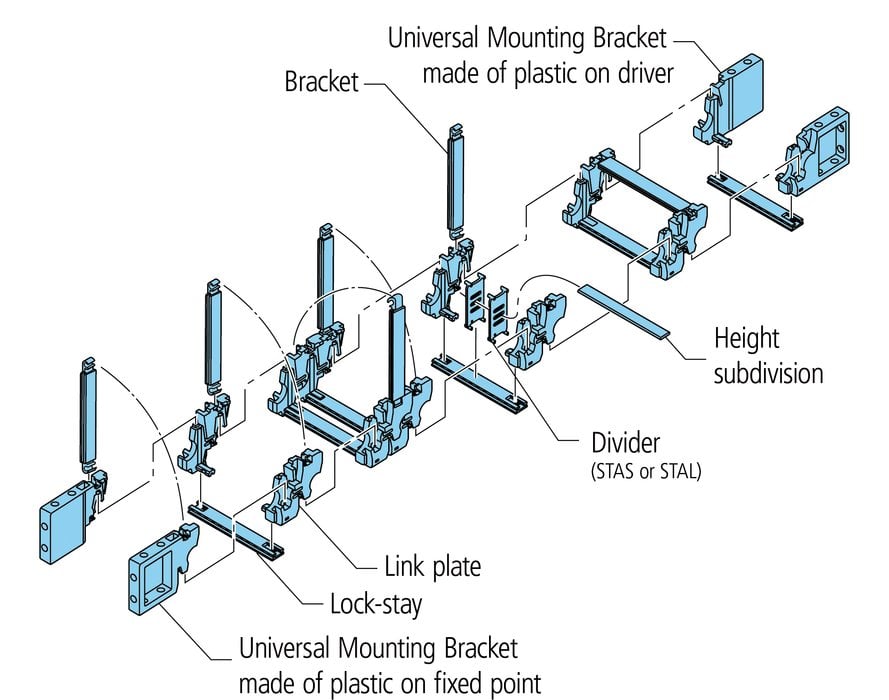

The stroke system used to control the bending of the link plates has been reconfigured to further reduce contact shock. This has resulted in a noise reduction of up to 4dB (A) compared with the previous generation of TKR0200.

2. Increased protection for cables & hoses as well as educed dust generation

We have introduced a superior slippery material for the brackets (outer circumference) and lock-stays (inner circumference). What’s more, we have provided increased protection for cables and hoses by redesigning the shape of the surface that contacts the cables and hoses. This innovation has contributed to a further reduction in dust generation.*

*Achieves ISO Class 1 cleanliness even when urethane tubes are used (according to results of our tests conforming to ISO 14644-1 “Classification of Air Cleanliness” at air velocity of 120 m/min).

3. User-friendly design features brackets can be opened/closed from either side.

The brackets (on the outer circumference) are double-hinged to allow opening and closing from either side, and the lock-stays are removable. This allows for easier opening/closing of bracket and placement of lock-stays as well as more secure placement of cables and hoses.

Applications

Semiconductor/LCD fabrication equipment; solar panel/solar cell manufacturing equipment; precision machinery; and a wide range of other applications requiring low-noise operation and low dust generation

Available sizes

Model TKR0200 with 20 mm pitch

Inside width (Bi): 40/50/60/80/100/120 mm

Bend radius (KR): 55/75/95/150 mm

Turnaround time

Made-to-order product