www.industryemea.com

11

'12

Written on Modified on

MapleSim Breaks New Ground in Hardware-in-the-Loop Real-Time Simulation for Planetary Rovers

In the space industry, the design, building and testing of rover prototypes is extremely expensive and system testing typically does not occur until late in the design/testing process, leading to a long development time. In response to this, Dr. Amir Khajepour, Canada Research Chair in Mechatronic Vehicle Systems and Professor of Engineering in the Mechanical and Mechatronics Engineering department at the University of Waterloo (UW), and his team worked with the Canadian Space Agency (CSA) and Maplesoft, to develop a Hardware-in-the-Loop (HIL) test platform for solar powered planetary rovers.

Using this test platform, scenarios that are hard to replicate in a lab setup, such as the Martian environment, or components that are not yet available, can be modeled while hardware components that are available can communicate with these software models for real-time simulations. The goal is to progressively add hardware components to the simulation loop as they become available. In this way, system testing takes place even without all the hardware components, bridging the gap between the design and testing phases.

The main advantage of this approach is that it significantly reduces the overall development time in the project. In addition, this allows for component testing under dangerous scenarios without the risk of damaging a full rover prototype.

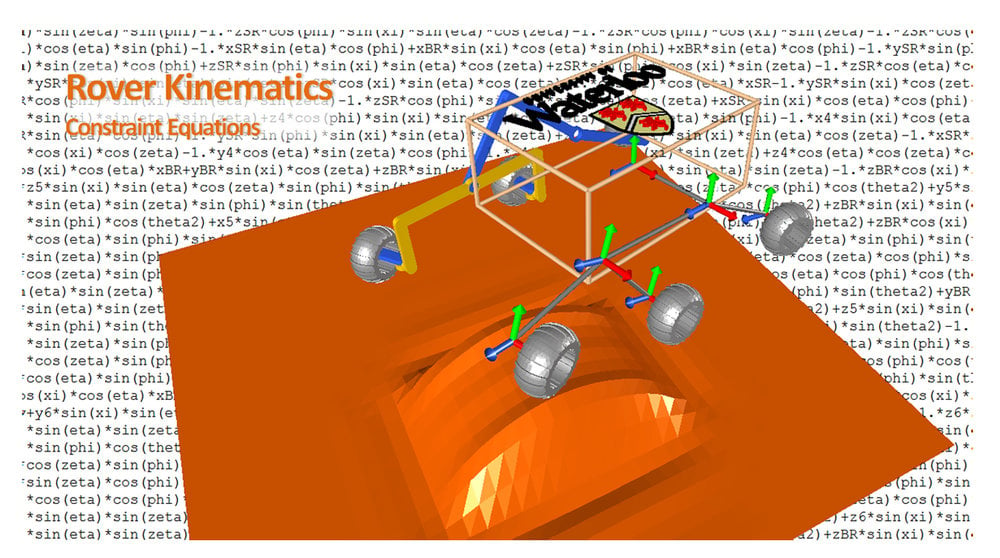

Rover Kinematics

In addition to simulating the rover dynamics, the MapleSim modeling environment was used to automatically generate the kinematic equations of the rover.

These equations then formed the basis for other tasks in the project such as HIL simulations, path planning, and power optimization. The modular system setup enables users to quickly change the rover configuration and explore different approaches in a short time.

Figure 2 shows an overview of the test platform. Information regarding the rover’s position, orientation, tilt, speed, and power consumption (obtained from dynamic models of the rover) is used as input to the software models. A library of rover components was developed within MapleSim and imported within LabView Real-Time where the HIL program and GUI of the simulations were developed. The program was then uploaded to the embedded computer within National Instruments PXI where communication between the hardware components and the software models was established and the real-time simulation was run.

“Due to the multidomain nature of the system (mechanical, electrical and thermal), it was desirable to model all the components within one modeling environment such that critical relationships can be easily discovered. In addition, computational efficiency is crucial in real-time simulations,” said Dr. Khajepour. “MapleSim was found to be the ideal environment for this application due to its multidomain abilities, use of symbolic simplification for higher computational efficiency and ease of connectivity to LabVIEW.”

In addition to making use of MapleSim’s built-in component library, custom components were also easily developed. A model to estimate the solar radiation that a tilted surface would receive on Mars was implemented using MapleSim’s Custom Component Block. This model took into account the sun’s position, the rover’s latitudinal and longitudinal position as well as orientation and tilt as it traveled from point A to point B. This was used together with a solar array model to estimate the power generation of a rover throughout the day.

“The intuitive nature of MapleSim allowed my team to create high fidelity models in a short period of time,” said Dr. Khajepour. “This played a key role in the success of this modular HIL test platform which allowed for component testing, power level estimation, as well as the validation of power management and path planning algorithms.”

The team also used MapleSim as a key tool in an earlier part of the project to develop a full solution for the power management system of autonomous rovers. They used MapleSim to rapidly develop high fidelity, multidomain models of the rover subsystems. The goal was to develop a path planning algorithm that took rover power demands (and generation) into account. Using the models developed, the path planner found the optimum path between point A and point B, such that the rover maintained the highest level of internal energy storage while avoiding obstacles and high risk sections of the terrain.

Dr. Khajepour and his team were able to create the mathematical model of the 6-wheeled rover without writing down a single equation. “MapleSim was able to generate an optimum set of equations for the rover system automatically, which was essential in the optimization phase,” he said. Dr. Khajepour was also impressed with MapleSim’s graphical interface. “In MapleSim, you can simply re-create the system diagram on your screen using components that represent the physical model. The ability to see the model, to see the moving parts, is very important to a model developer,” he concluded.

Figure 1 - Automatic generation of kinematic equations

Figure 2 - Hardware-in-the-Loop Framework

Figure 3 - Solar Array Model in MapleSim