www.industryemea.com

26

'19

Written on Modified on

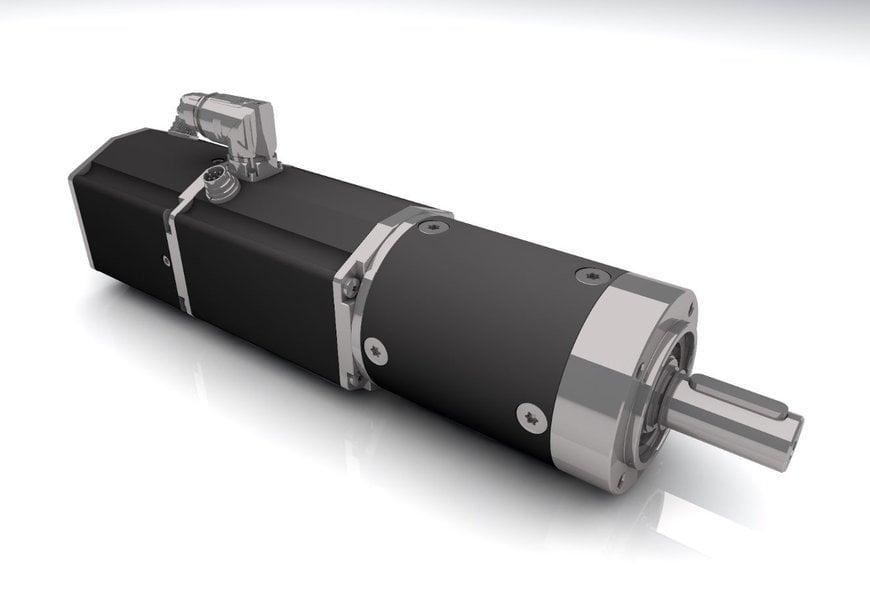

PROFINET NOW ALSO FOR LOW-VOLTAGE DC MOTORS

Dunkermotoren - An innovative manufacturer of motor technology.

Dunkermotoren GmbH, based in Bonndorf in the Black Forest, has been dedicated to motor technology for more than 60 years and is one of the first brushless drive technologies in the low-voltage sector. For more than 30 years the company has been developing brushless motor technology and offering synchronous three-phase AC motor technology.

First, in the mid-1980s, a simple 4-phase technology was introduced, which was still expensive and inefficient as a semiconductor technology.

With the breakthrough of the three-phase technology, Dunkermotoren also took the development step towards this technology. Since 1999 - with the development of the BG 65 and a new winding technology - the foundation stone was laid for today's successful drive family. The industrial portfolio ranges from the 45 mm size with the characteristic 8-corner housing with approx. 40 W output power to today's flagship with 95 mm square and over 1100 W nominal power. The latest and at the same time smallest member of the drive family is the BGA 22 (22 mm construction diameter) with a power output of 18 – 23 W.

Dunkermotoren - A product partner

The reliability of the drives in the various applications is known on the market, which is why SIEMENS also became aware of the products of Dunkermotoren. For the latest development in the field of drive controllers - the SIMATIC MICRO-DRIVE - the company was looking for a complementary motor portfolio that could set standards in the low-voltage sector. This was found with the BG series of Dunkermotoren motors. Together with the modular system that Dunkermotoren has pursued from the very beginning, the standard catalogue already offers a multitude of combination options.

This opens up a whole universe of drive solutions in the lowvoltage sector for the developer of machine tools, strapping systems and format adjustments. Together with the possibility of adapting both the mechanical and the electrical interface to specific projects, almost every wish can be fulfilled.

SIMATIC MICRO-DRIVE - The smart solution for industrial applications

The special feature that the SIMATIC MICRO-DRIVE now offers the user is the "Plug and Play" solution. This is made possible at the start of the project by the mechanical, electrical and thermal design of the drive axle with the help of the TIA Selection Tool. The coordinated components of the motor and the SIMATIC MICRO-DRIVE controller, together with a patented file transfer, set the controller to a preset state after connecting it to the motor.

All of this can be processed by the TIA portal with operator guidance. Cumbersome drive tuning and parameterization of the controller control loops are a thing of the past. Under normal drive load conditions, the drive train can be put into operation immediately without any problems. Of course, it is still possible to optimize the parameterization itself under unfavorable conditions. However, this will no longer be necessary in 80% of applications.

SIMATIC MICRO-DRIVE - The technology behind it

The strength of the SIMATIC MICRO-DRIVES for the user is certainly the self-parameterization of the system. This is realized in the system through the use of modern electronic components. A special singleturn absolute encoder reads out the commutation point for the drive and works as a high-resolution encoder system together with the controller. A patented data transmission system provides commutation and parameter data from the drive when the unit is switched on.

The drive informs the controller in detail which nominal data the motor have and which parameters the gear unit and an optional brake have, as well as boundary parameters which must not be exceeded by the drive. This protects the entire drive train from inadvertent incorrect parameterization, that makes commissioning easier for the user. In the next step, a multiturn encoder is planned as an extension, which will be available later.

Together with the modular system, the SIMATIC MICRO-DRIVE thus offers a versatile application landscape for simple standard commissioning.

SIMATIC MICRO-DRIVE - The safety drive

In addition to simple commissioning, this powerful drive concept also offers other functions that are becoming more and more important in mechanical engineering today. This drive solution shows its strengths in the area of "functional safety". Due to the modular design of the controller in conjunction with the powerful drive, this solution is a must for the safety-conscious engineer.

www.dunkermotoren.com