www.industryemea.com

28

'12

Written on Modified on

From Weakest Link to Machining Superstar

Why New Spindle Connection Maximizes Metal Removal

Mark Huston, Vice President, Global Engineered Solutions

Doug Ewald, Director, Global Product Management, Tooling Systems

Ruy de Frota de Souza, Manager, Global Tooling Systems, Product Engineering

Kennametal Inc., Latrobe, PA

Machining tough materials like titanium is a challenge on its own. Machining hard alloys with the additional pressure of achieving improved production efficiencies means maximizing metal-removal rates in the face of low cutting speeds and significant cutting forces. Machine tool builders have responded with specialty milling and turning centers that feature improved stiffness and damping on spindles and sizable machine structures, all to minimize undesirable vibrations that deteriorate part quality and tool life. Although these advances have added to greater productivity, the weakest point has often been the spindle connection itself.

In most cases, the tool-spindle connection determines how much material can be removed on a given operation. This is because this interface must withstand high loads and yet maintain its rigidity, until tool deflection is too high or the onset of chatter is reached. With the ongoing advances in cutting tools and machining centers, a spindle connection that makes the best utilization of available power possible is an important consideration to investigate early in production planning.

Several types of spindle connection have been developed or optimized over the last few decades. Due to a good cost/benefit position, the 7/24 ISO taper grew into one of the most popular systems in the market. It has been a success in many applications, but accuracy and high-speed limitations prevent it from growing further.

The advent of face contact represented a major step over the standard 7/24 taper. The combination of face contact with the 7/24 solid taper provides higher accuracy in the Z-axis direction, but also presents some disadvantages, namely loss of stiffness at higher speeds or high side loads. Most tools in the market are solid and the spindles have relatively low clamping force. Connection stiffness is limited, as radial interference needs to be kept to a minimum. The required tolerances to achieve consistent face contact are thus very tight, leading to high manufacturing costs.

In 1985, Kennametal and Krupp WIDIA initiated a joint program to develop a universal quick-change system, now known as KM™ and recently standardized as ISO 26622. In the early 90’s the HSK system started being employed on machines in Europe and later became DIN 69893, then ISO 12164

KM™ quick-change tooling consists of two basic components: the clamping unit and the cutting head. The clamping unit mounts to the machine tool (a turret or tool block for stationary applications and a rotating spindle to accommodate rotating applications) and is the receptacle for the interchangeable cutting unit/toolholder. When a tool change is necessary, an operator simply releases the locking system, replaces the cutting unit, and locks it into position. Machine downtime is a matter of seconds.

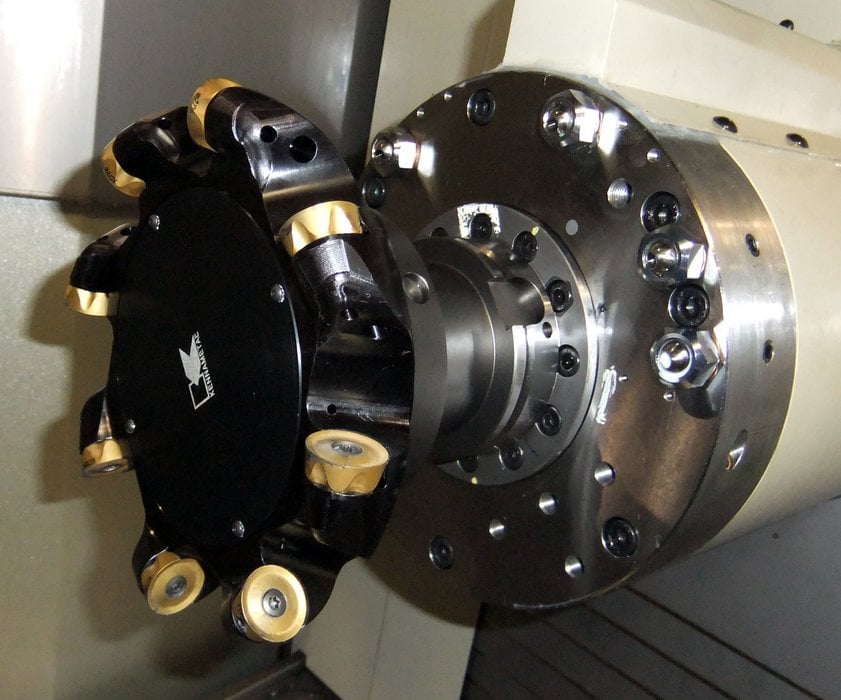

KM4X™ from Kennametal represents the next generation of KM. Some systems may be able to transmit a considerable amount of torque, but cutting forces also generate bending moments that will exceed the interface’s limits prior to reaching torque limits. By combining high clamping force and optimized interference levels, KM4X provides a robust connection, extremely high stiffness, and bending load capacity for greatly improved performance in machining high-strength alloys and other materials, enabling extremely high metal removal rates and more completed parts per day.

3X Improved Bending Moment Resistance

The spindle connection must provide torque and bending load capacity compatible with machine-tool specifications and the requirements for higher productivity. It becomes obvious in end-milling applications, where projection lengths are typically greater, the limiting factor is the spindle interface’s bending capacity. As an example, an indexable helical cutter with 250mm (9.84 in.) projection from spindle face, 80mm (3.15 in.) in diameter generates 4620 Nm (3407.5 ft. lbs.) of bending moment and less than 900 Nm (663.8 ft. lbs.) of torque when removing 360 cm3/min of Ti6Al4V at RDOC of 12.7mm and an ADOC of 63.5mm.

The most critical parameters of a taper-face spindle connection are the clamping force and radial interference. Maximizing clamping force and selecting appropriate values of interference can further improve connection rigidity.

By using three-surface contact for improved stability and optimized clamping force distribution and interference fit, KM4X™ engineering results in three times the bending moment resistant capacity compared to other tool systems.

This means:

-Shops can leverage KM4X-equipped high-performance machine tools to increase speeds and feeds in difficult machining applications, thus gaining the full productivity potential from the machine tool.

-Often, a smaller KM4X connection such as a KM4X100 will provide the same or better cutting performance of a larger connection.

-KM4X systems can be applied on multi-tasking, turning, machining centers and transfer machines in manual, semiautomatic, or fully automatic mode.

KM4X by design can perform in a wide range of operations, from low-speed/high torque to high-speed/low torque, allowing manufacturers to get the absolute most out of their production equipment

Milling, drilling, and turning a wide range of materials just got more productive!

Rules and recommendations are by nature general. For specific advice regarding titanium machining and more on KM4X, contact Kennametal or visit www.kennametal.com.

KM4X_with_cutter.jpeg: By combining high clamping force and optimized interference levels, KM4X provides a robust connection, extremely high stiffness, and bending load capacity for greatly improved performance in machining high-strength alloys and other materials, enabling extremely high metal removal rates and more completed parts per day.

KM4X_8.jpeg: The KM4X™ spindle-connection system from Kennametal has a heavy-duty configuration capable of performing in high-speed, low-torque or low-speed, high-torque conditions. Without KM4X, helical cutters such as this would exceed bending moment constraints long before reaching torque limits.

KM4X_9.jpeg: Surface contact and clamping force combined for improved interference fit and three times the bending moment resistance compared to other systems. Tool change is quick and easy, minimizing machine downtime.