www.industryemea.com

27

'20

Written on Modified on

DUNKERMOTOREN SUPPLIES CENTERPIECE FOR MOBILE ROBOT PLATFORM “HORIZON XIX“ FROM FRANKFURT UNIVERSITY OF APPLIED SCIENCES

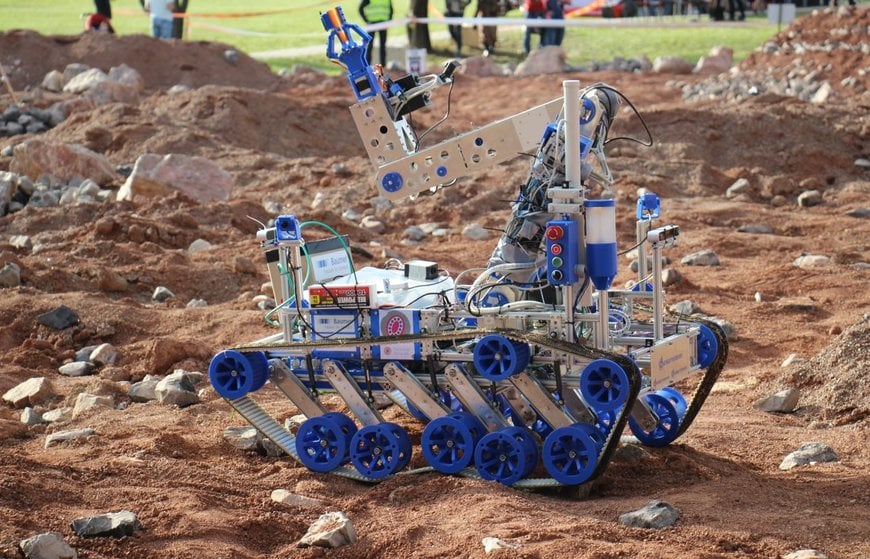

Students of the Frankfurt University of Applied Sciences develop the mobile robot platform (rover) “Horizon XIX“ for the international student competition “European Rover Challenge“. The rover is dimensioned for the mars-like challenges of the competition. Smart Dunkermotoren motors of the BG 65S series form the centerpiece of the rover, they power the chassis.

Frankfurt University of Applied Sciences & European Rover Challenge

Four faculties, 70 versatile degree programs, over 15,000 students, the Frankfurt UAS builds on the future – integrated, sustainable and application-oriented. Since the winter-term 2016/17 Faculty 2: IT and Engineering, offers the master’s degree “Mechatronics and Robotics (M.Sc.)“. The idea: concentrating projects of multiple students, to work on ambitious topics in the field of robotics.

The European Rover Challenge is one of the biggest international space and robotics events in the world1 and takes place in Poland, since 2014. The student competition is the highlight of the event. Approximately 60 universities from all over the world apply for participation. Teams composed of students from one university, develop and build a proportionally large and partially automated “Mars-Rover” for the competition. The teams show off their skills and competences in different disciplines within a highly competitive environment.

FRoST & Horizon XIX

Students of the Mechatronics and Robotics program founded the “FRoST - Frankfurt Robotics Science Team“, in late 2018 for the participation at the ERC-competition. In 2019, FRoST achieved the 23rd place² out of approx. 40 qualified teams with their rover “Horizon XIX“, for their first participation.

Horizon XIX is divided into four key components: the chain-based chassis, the 5-axle robotic arm, the drilling unit and the ground station. The chassis measures 1270 mm x 788 mm in length and width and disposes approx. 220 mm of ground clearance. Two Dunkermotoren drives mounted transversely in the center, with a 180° offset, power the chassis, see graphic “Rover “Horizon XIX“ top view – Detail view without drive chain“. Torque is transferred by a toothed belt. The powerful Dunkermotoren drive units consist of a BLDC-motor of the BG65Sx50 series, the planetary PLG 63LL gearbox, as well as the brake/encoder-combination E90 + RE30-3-500TI24.

Considering the chassis geometry and the requirements of the European Rover Challenge regarding the maximally permitted rover speed of 0.5 m/s, a reduction ratio of i = 29.4:1 has been chosen. The exact specification at the maximally permitted speed was done by software. A 32-bit microcontroller with real time operating system, acting as “master“, located on top, connects the rover. Ground station and microcontroller exchange information via WLAN IEEE 802.11.a/n.

The network protocol UDP is used. The drives are controlled through the BGE 6010 A control electronics from Dunkermotoren. The control electronics is based on an H-bridge. Data exchange between control electronics (device profile CiA 402) and microcontroller happens via CANopen, see graphic “Rover “Horizon XIX“ – System architecture chassis“. The microcontroller communicates via the self-developed CANopen Library.

When a new movement command occurs via the joystick, the brake is released first, the CiA 402 Power State Machine is run through until the state “Operational enabled“ is reached. In this state, tension for the controller is switched on and torque released. The microcontroller converts the joystick movement into speed for both motors and writes via CANopen message in the object dictionary. The control electronics now executes the run-up at the desired speed.

The rover “Horizon XIX” masters the uneven “mars terrain“ at the ERC 2019, with obstacles sometimes the size of a medicine ball, without any problem. The chain chassis in combination with the powerful drive units from Dunkermotoren allows for precise control of the rover in difficult terrain.

www.dunkermotoren.com