www.industryemea.com

12

'20

Written on Modified on

Cooperation with MARPOSS: reduced setup times and maximum tool service life

The optimal and longest-possible use of tools represents a vital cost factor for machining companies. But compromises are often necessary – particularly in series production and as part of automated processes. Tools with a defined tool life are replaced as soon as the specified tool life has come to an end. In many cases, though, the tool has not truly reached the end of its tool life and replacement is not yet necessary. However, companies play it safe to avoid quality issues and the risk of producing items that later need to be rejected.

This is one of the elements addressed by the ARTIS GENIOR MODULAR module by MARPOSS. The fully automatic tool- and process-monitoring system has been an established feature of the market for many years. It works by recording various measurements and assessing them on the basis of several criteria. For example, the module can measure the force that needs to be generated during the machining process. This enables the system to identify tool wear and potential tool fractures. The current status is shown on the machine control operating display or via a connected computer. By taking the measurements into account, tools can be used up to the true end of their tool life. The entire system is protected by the measurements taken by the module.

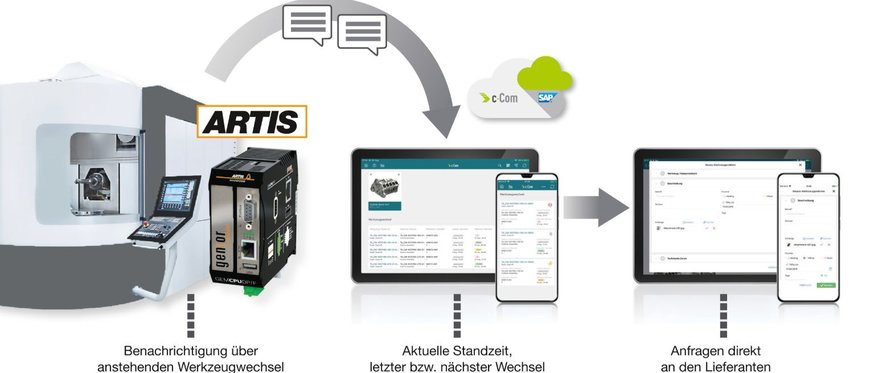

MARPOSS recently launched a collaboration with c-Com GmbH and its c-Com open cloud platform to provide module users with additional value: the ARTIS GENIOR MODULAR module and c-Com are set to exchange data. Once the defined tool limits have been reached, the staff member responsible receives a notification on their mobile terminal – which is made possible by the cooperation with c-Com. As a result, operators can react more quickly and boost the efficiency of their manufacturing processes.

The exchange of data also helps to forecast for upcoming tool changes. Depending on the user’s preference, c-Com creates an overview showing a time limit or the number of workpieces remaining. With this information, it becomes possible to stock up on new tools at production facilities in good time. This reduces setup time and machine downtime caused by unavailable or unprepared tools. The number of spare sister tools can be minimised and fewer tool mounts are required.

At EMO 2019, MARPOSS and c-Com showcased the results of this promising collaboration – which is set to be intensified – for the very first time.

Cooperation with Oerlikon Balzers: transparency and sustainability thanks to digital processing for coating

Many tools are re-sharpened and re-coated to make production as cost-efficient as possible and to use raw materials sustainably. During this reconditioning process, the tool passes through several stages, which are usually carried out by different companies. Tools are recorded several times to allow the processing of orders and to enable them to be assigned accordingly.

This procedure is very complex for everyone involved – from the machine operators to the staff members carrying out the re-sharpening and coating. Physical product cards accompany the orders throughout the entire process chain. If a staff member responsible for re-sharpening sends a tool for coating, this staff member is often not aware of corresponding order status. This results in frequent queries. Neither tool users nor the coating and re-sharpening staff have an oversight of how many times the tool has been re-sharpened or coated in the past. In some cases, the number of re-sharpening processes is simply marked on the tool shank. Overall, the total benefit is reduced by the very high investment of time and effort required.

In cooperation with Oerlikon Balzers, c-Com has developed an application that enables significantly more effective and transparent order processing. The prototype was showcased at EMO Hannover. The only prerequisite to benefitting from the advantages of digital processing for coating is identifying all tools with a unique ID.

The c-Com application exchanges data with the myBalzers customer portal run by Oerlikon Balzers. This way, the entire order process is digitalised, and all receipts are available online. It is easy to share documents such as delivery slips, invoices or order confirmations, and the status of each coating order can be viewed in real time. There is no longer a need to ask for order updates – a quick glance at the application provides the user with all the information they need.

The speed of the overall order process is also increased as the recorded data is made available for all successive steps. Tools are returned from reconditioning after a shorter period of time. As a result of significantly reducing the manual data input, the process is no longer as susceptible to errors.

On top of that, machine operators have access to all the important information about their tool at all times. Thanks to the collaborative approach by c-Com, they can access all data via the cloud. They know how many times their tool has been re-sharpened and are provided with comprehensive information on the coating. This data is extremely useful for the optimisation of processes. If the tool’s performance drops, the cause of any issues can be established and resolved much more quickly.

Involving coating staff significantly enhances the networking of the entire supply chain and serves transparency. This is one of c-Com’s key objectives for the open cloud platform.

www.mapal.com