www.industryemea.com

08

'13

Written on Modified on

TWO OUT OF THREE AIN’T BAD

New RVM systems offer the best in both safety and availability

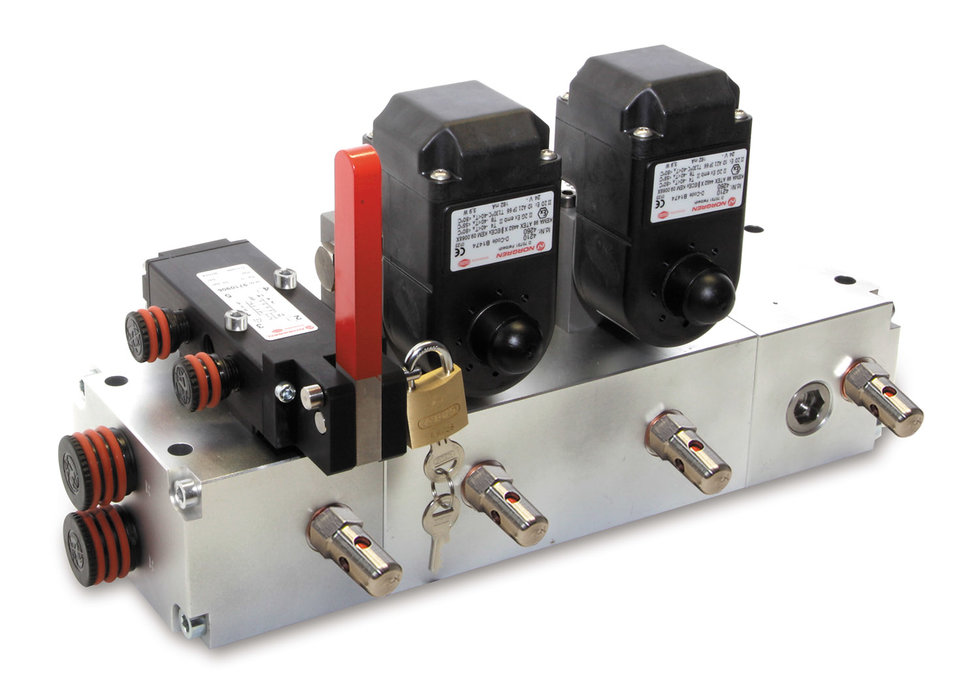

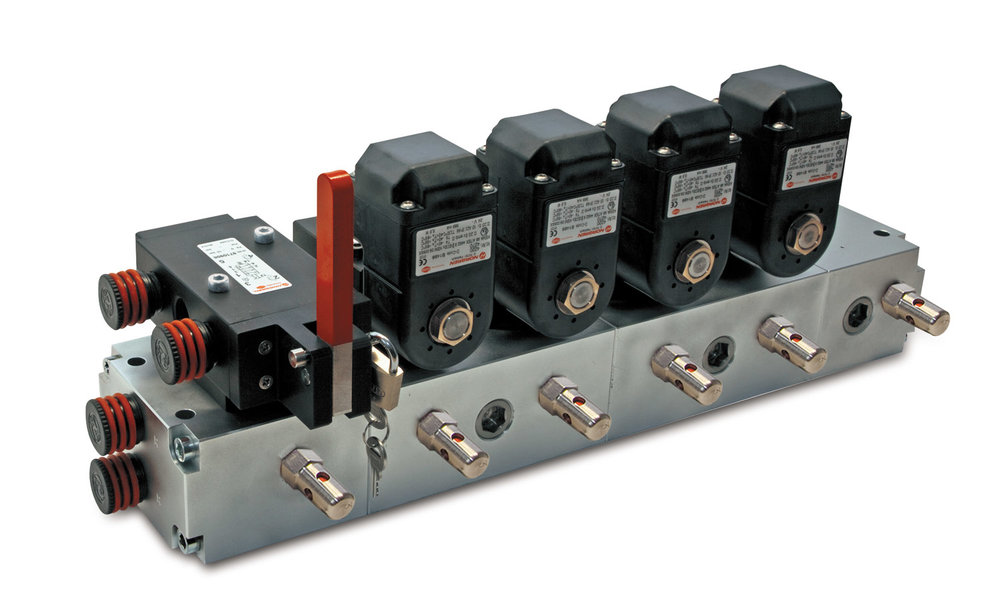

Available in aluminium or stainless steel to suit both upstream and downstream applications, Norgren RVM (Redundant Valve Manifold) products eliminate the need to create separate systems combining valves and pipes by incorporating all functions governing both safety and availability in a convenient, simple to install, low-maintenance integrated valve control unit.

The products are designed to replace piped or ‘nippled’ systems, providing redundancy in the event of valve failure while increasing time intervals between plant turnarounds and delivering a variety of circuit functions without the need for pipework.

Customers can select from one out of two (1oo2), two out of two (2oo2) and – unique to Norgren – two out of three (2oo3) set-ups, to cover all requirements for both safety and availability.

The compact, modular systems draw on proven valves from Norgren’s Herion and Maxseal product ranges, with options suitable for both standard and high flow applications.

Approved to all major industry standards, Norgren RVM systems significantly reduce potential leak paths, while for the first time there is no need to interrupt processing to install, service or replace a valve. All RVM systems are suitable for on-line control with a bypass function enabling on-line valve removal – a key benefit for systems operating in remote locations.

Visual indicators and proximity sensors provide a clear indication of valve position and output status, while integral exhaust guards prevent particle ingress from the environment. Operating temperatures range from -55ºC to 90ºC.

Jon Taylor, Sector Head – Energy at Norgren, commented: “RVM products are a great example of Norgren’s ‘Engineering Advantage’ strategy of developing innovative high performance products based on customer requirements for greater control without compromising either safety or availability. They deliver in a convenient single package a safety-approved system which requires minimal maintenance and can operate in the most demanding environments while able to be simply and remotely controlled in real time.”

For further information on Norgren visit www.norgren.com/cn/rvm.

About Norgren

A world leader in pneumatic motion and fluid control technologies, Norgren works closely with customers to gain a deeper understanding of their engineering needs, and then connects its people, products and expertise to give their equipment and their business a clear advantage. Norgren’s reputation rests on a world-class portfolio of high performance products, the innovation and technical expertise of its 6000-plus people, and an ability to deliver exceptional local service. A subsidiary of the £2.13 billion turnover engineering group IMI PLC, Norgren has a sales and service network in 75 countries, technical centres in the USA, Germany, UK and China, and manufacturing facilities around the world.

www.norgren.com