New Sensor Technology for Servo Components Helps Deter Line Downs and Optimize Machine Uptime

Self-monitoring servo gearboxes track temperature, vibration, acceleration and more.

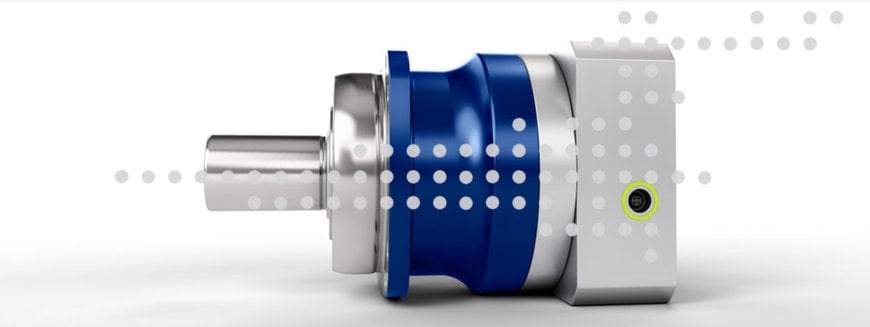

WITTENSTEIN SE has launched a new sensor technology, cynapse, designed as a self-monitoring gearbox with built-in tracking of vibration, temperature, acceleration and mounting position of the gearbox. Designed to promote machine uptime and deter line downs, the high-precision servo gearbox with cynapse sensor technology consists of three significant features:

- Product Identification: The gearbox features a digital identification plate that contains the product’s unique component ID.

- Threshold Monitoring: Embedded sensor technology monitors pre-defined values and thresholds for vibration, temperature, acceleration and mounting position, and sends this info to the IO-LINK Master where it can be shared to the plc IPC gateway cloud.

- Data Logger: Performance data for vibration, temperature, acceleration and mounting position is stored throughout the component’s lifecycle. A built-in anomaly detector scans this aggregated data for trends or abnormalities that may occur over time and notifies the control system of potential issues.

Immediate Results

This component-based solution does not require an update to every axis on the machine. Simply installing one cynapse gearbox on critical axis can significantly deter chances of a line-down occurrence. Of further benefit to existing WITTENSTEIN customers, cynapse gearboxes are evolved versions of existing products, enhanced with the new self-monitoring technology. This means existing drive systems with WITTENSTEIN servo gearboxes can be upgraded with cynapse gearboxes without any design modifications to the machine. The design, contour and size of the cynapse gearbox is identical to the original alpha gearbox, allowing for a simple drop-in replacement.

How it Works

cynapse generates a kind of electronic “fingerprint” of your specific performance, efficiency, transparency and availability requirements. The smart gearbox is able to identify and measure influencing quantities directly in the process and the environment, and then pass them on to the machine control. Furthermore, gearboxes with cynapse can exchange information with applications on IIoT platforms and execute intelligent monitoring activities independently using integrated logic functions that are capable of “thinking”.

cynapse gearboxes measure temperatures and report overheating; they detect vibration and they count operating hours. They store and document all events linked to their use – all data relevant for preventative gearbox maintenance is supplied systematically. This minimizes the risk of gearbox damage and prevents machine downtime. In short, cynapse makes a decisive contribution towards optimal machine availability and productivity.

Benefits

cynapse provides a simple way to connect your gearbox to tomorrow’s digital world. Using the connectivity of an IO-Link interface, a sensor module is integrated into the existing installation space. You then have access to measured variables such as temperature, vibration, operating hours and acceleration as well as product-specific information on the gearbox.

- More functionality from the same space.

- Gain access to information without having to mount any additional sensors externally.

- Integration without limits

- Implemented seamlessly in your system landscape with an integrated sensor module and an IO-Link interface.

Self-monitoring gearboxes from WITTENSTEIN alpha feature cynapse sensor technology, and make drive trains fit for digital transformation. The sensor element, evaluation and logic functions are seamlessly integrated – while the IO-Link interface ensures universal Industry 4.0 connectivity.

www.wittenstein-us.com