www.industryemea.com

29

'13

Written on Modified on

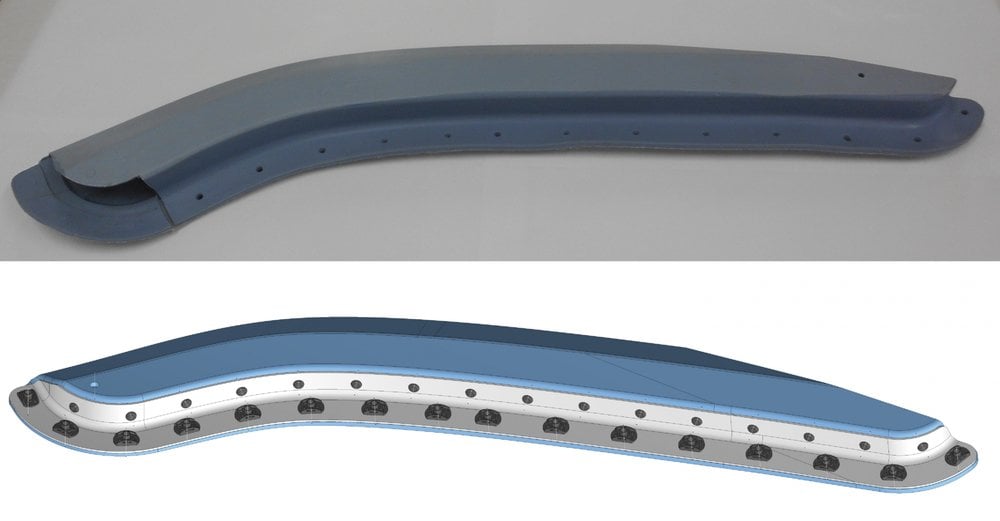

New lighter weight material set to bring major savings in fuel consumption

Icon Polymer Group, a technology company in engineered polymer products, has delivered a major boost to designers seeking to minimise aircraft weight and fuel consumption, with the introduction of a revolutionary new lighter weight material for aircraft seals.

Based on a proprietary technology through which hybrid polymers can be produced to exhibit a wide range of performance attributes, ICONlite™ represents a major step forward in low weight seals. It even allows variable densities to be tuned to the requirements of the platform.

Icon Polymer’s own research estimates a total fuel saving in the region of US$5 million in one application, based on the use of ICONlite™ seals creating a 240kg weight saving on an aircraft flying for a total of 700,000 hours, with a cost per gallon of US$3.09 for kerosene type jet fuel.

Icon Polymer is an established supplier to the global civil and military aerospace sectors, with customers including Airbus, Bombardier and Gulfstream.

Tim Pryce, Chief Executive Officer of Icon Polymer Group, explained: “The unique ‘backbone’ of silicone rubber allows it to perform consistently over a wide temperature range, with excellent environmental resistance, which has over the years made it the material of choice for specifiers of seals.

“However, mindful of the ever-increasing drive to reduce aircraft weight and therefore fuel consumption, our team of engineers have applied their extensive materials knowledge to create a lighter weight solution which does not compromise on performance.

“The potential savings are massive and we are already in conversation with several leading global manufacturers and tier one suppliers about the integration of ICONlite™ products into their designs.”

One of the world’s most innovative engineered polymer and elastiomer solutions providers, Icon Polymer is applying its technology-based approach to electrically and thermally conductive, variable elasticity polymers, producing aerospace engineers with a wider choice of technologies. The company offers a complete service, from innovative design and competitively-priced production to responsive expert service and global aftermarket support.

For further information on Icon Polymer Group visit www.iconpolymer.com.