www.industryemea.com

30

'13

Written on Modified on

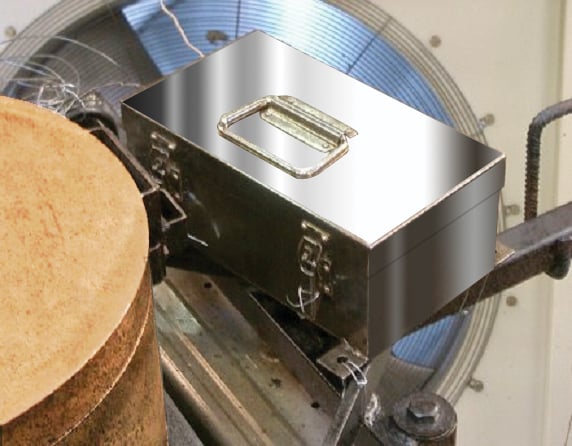

Temperature profiling inside the mold: RotoPaq for rotomolding applications

Cambridge, UK – For optimal temperature control in rotational molding processes, Datapaq now provides the RotoPaq system which can collect data directly from inside the oven, mold surface, and even within the mold. The data logger, thermal barrier, and thermocouples are attached to the rotating mold assembly to record temperature data throughout the continuous heating and cooling cycles. In addition to being stored in the logger, the data can be transmitted in real time using radio telemetry. The temperature profile enables users to control and optimize the process in order to avoid common manufacturing defects such as warping, pinholes/bubbles, discoloration, and uneven impact resistance, thus ensuring both high product quality and efficiency. The RotoPaq system is routinely used to validate new materials and processes or when environmental conditions change. Its excellent thermal protection allows continuous operation for up to 14 hours. Datapaq also provides thermal barriers for use in water shower cooling. The Insight analysis software enables quality control certification for customers or according to industry standards such as QS9000.