www.industryemea.com

15

'20

Written on Modified on

Technology Report

Efficient material flow with complete safety.

The increasing automation of processes places growing demands on safety concepts. Classic concepts such as muting, for example, are often pushed to their limits. The intelligent safety solutions from Leuze enable complete safety, efficient material flow, and high system availability.

Individually tailored system solutions

The innovative safety concepts are at the heart of every Leuze safety solution. They primarily address safeguarding tasks where safety-related processes are part of the solution. The safety concepts are individually adapted to the respective system layout, or even expanded or newly designed where needed. During each project, certified Leuze safety consultants assess the customer's requirements and subsequently accompany them through to the on-site safety acceptance. In addition to providing the necessary hardware and software components, Leuze safety solutions include the configuration and parameterization of the system as well as start-up support. Leuze can draw from an extensive range of in-house safety products for the implementation of safety solutions.

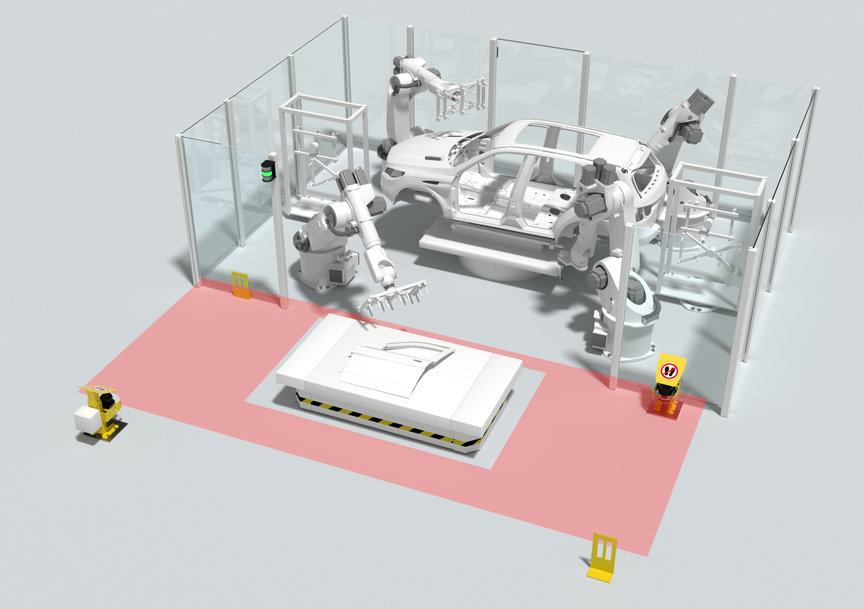

Dynamic safeguarding of AGV/robot transfer stations

In flexible production processes, AGVs are often loaded and unloaded by robots. This means that the safety concepts for the AGV/robot transfer stations must be designed for automated movements. Leuze's safety solution dynamically safeguards the area of the transfer station. The area is monitored by two safety laser scanners. When the vehicle enters the monitored area, the monitoring dynamically adapts to the vehicle position and blanks out the AGV footprint from the monitored area.

The advantage of this solution is that the presence of people or their entry is continuously monitored. The vehicle can move through the monitored area during the loading cycle while the surroundings of the vehicle are fully guarded at all times. This means that it is possible to reliably detect whether a person is walking next to the vehicle. The safety solution also allows vehicle loads with different widths and the transport of parts that protrude at the front. The system works autonomously and can be easily integrated into the safety circuit of the system via the 2-channel safety output.

Access guarding on multi-track transport systems

Multi-track transport systems often require a safety concept that ensures smooth processes and complete safety at the same time. The suitable Leuze safety solution is shown at the example of a pallet discharge via gravity conveyors, which is fed by a cross conveyor. Access guarding takes place via two vertically oriented safety laser scanners. These monitor the entire transfer area of the cross conveyor. By switching the protective fields, the protective function is only released for the conveyor on which a pallet is discharged. The safety system receives information about which conveyor is used from system control.

Complete access guarding also during pallet discharge

The advantage of this solution is that the entire access area is completely monitored at all times. It is also easy to set up and install, as it takes only two safety laser scanners to safeguard the entire transfer area. No additional trigger sensors are required. With conveyors in close proximity, only this solution enables a conveyor-specific safety concept.

Summary

The safety solutions from Leuze are based on innovative safety concepts that are individually tailored to the customer's system layout as part of the project. They ensure smooth-running processes with gapless safety and high system availability.