www.industryemea.com

29

'20

Written on Modified on

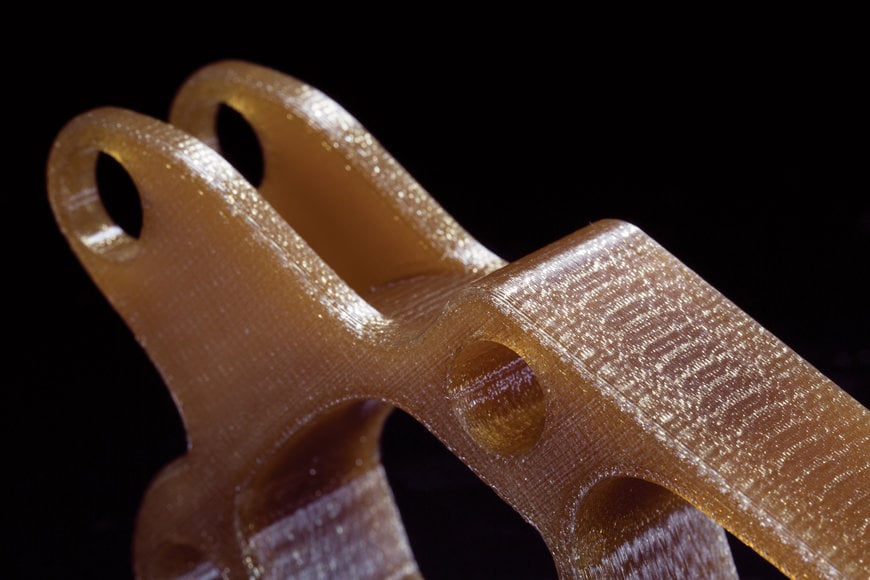

BOEING QUALIFIES STRATASYS ANTERO 800NA MATERIAL FOR 3D-PRINTED FLIGHT PARTS

Enhanced chemical resistance and fatigue performance of the PEKK-based material over other alternatives provide Boeing with a new, high-performance option for polymer flight parts.

Boeing (NYSE: BA) has qualified the Antero 800NA thermoplastic to its repertoire of 3D printing capabilities, Stratasys Ltd. (NASDAQ: SSYS) announced today. The qualification means the high-temperature material can now be used on flight parts for Boeing planes.

Antero 800NA is a PEKK-based polymer developed specifically for production-grade Stratasys FDM® 3D printers. Boeing has released specification BMS8-444 and added the 800NA material to the Qualified Products List (QPL) after an extensive evaluation of the material’s performance. It is the first material from Stratasys qualified by Boeing for use in applications with elevated chemical resistance or fatigue requirements.

“Boeing has recognized the tremendous utility of Antero to meet applications that couldn’t have been 3D-printed before,” said Stratasys Aerospace Vice President Scott Sevcik. “Additive manufacturing has tremendous benefits for simplifying aerospace supply chains both in original equipment and MRO, but robust materials for meeting challenging flight requirements have been needed.”

The Antero family of materials includes 800NA as well as Antero 840CN03, which is an electrostatic dissipative (ESD) variant. Stratasys provides these materials both for customers who use the Stratasys F900 and Fortus 450mc 3D printers and as a material option for on-demand customers through Stratasys Direct Manufacturing.

www.stratasys.com