Vestas and ZF Wind Power Launch First Serially Produced EnVentus Powertrain

ZF Wind Power and Vestas launched the world’s first serially produced EnVentus powertrain onto the wind market. The unique platform design is the result of intensive teamwork between both parties and is an answer to the development of next generation wind technology, lowering the Levelized Cost of Energy. Furthermore, it illustrates both partners’ competencies and the importance of this strategic partnership.

- World’s first serial powertrain for Vestas’ EnVentus platform is launched onto the wind market

- Vestas and ZF Wind Power bundled forces to anticipate the growth trajectory of renewable energy

- Customers all over the world will benefit from more flexible solutions and a wide range of customized turbine variants

With a contribution of more than 85 percent of renewable electricity by 2050, renewables will be the largest driver for change in the global energy transition according to the International Renewable Energy Agency IRENA (Global Energy Transformation Study 2019). Wind remains a competitive energy source and will collaborate with other main renewable energy sources.

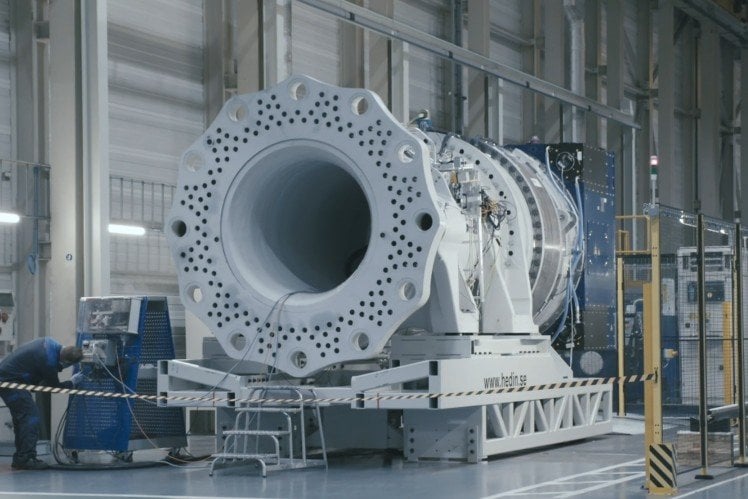

ZF Wind Power and Vestas bundled forces to anticipate the growth trajectory of renewable energy. After a dedicated period of development and enthusiastic teamwork, both parties are proud to release an integrated and modular powertrain design that includes main shaft, main bearing housing, two-stage planetary gearbox and permanent magnet generator. The EnVentus powertrain guarantees an output of up to 6.0 MW and is developed and tested at the facilities of ZF Wind Power in Lommel.

“With this strategic partnership, both partners leverage their respective advantages in engineering, innovation and market experience, while jointly producing high-reliable and cost competitive wind turbine technology for the fast-growing wind market,” says Tommy Rahbek Nielsen, COO of Vestas.

Customers all over the world will benefit from more flexible solutions and a wide range of customized turbine variants due to its modular design, competitive lifecycle costs, and a high-quality design which allows a fast integration in the customer development roadmap addressing new market segments.

As a result of its constant dedication to new technological innovations, ZF Wind Power built the powertrain which is the first of its kind in the global wind industry. “Its innovative, modular design and intelligent concept manifests ZF’s position as a global leader in the development of next generation wind turbine gearbox technology,” says Mitja Schulz, Head of ZF Wind Power.

www.zf.com