www.industryemea.com

10

'20

Written on Modified on

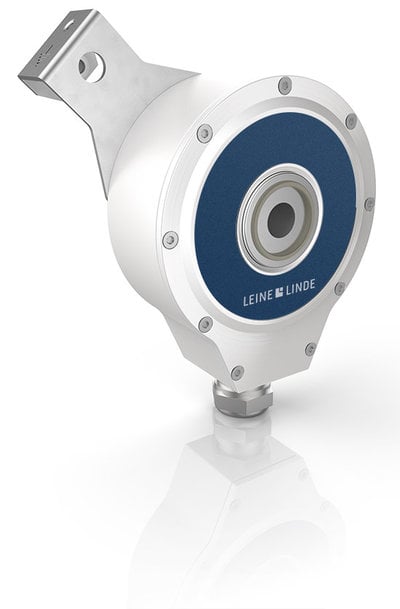

COMPACT ENCODER FOR USE IN AGGRESSIVE ENVIRONMENTS

In a cold rolling steel mill, very aggressive liquids are used in the rolling process, making it a very demanding environment. Not even an encoder in anodized aluminum would last here for more than possibly a year.

For one specific steel mill application, our customer needed a robust encoder with a big hollow shaft. The 700 series fit the specification perfectly – apart from the corrosion resistance. In order to offer a suitable solution, the Leine Linde engineers designed a 700 series encoder made from stainless steel, which is a material much more suitable for the aggressive environment of a cold rolling mill.

One important aspect we had to consider in this project was the added weight that comes with substituting aluminum with stainless steel. Not only must the encoder bearings be able to handle the extra strain without decreased performance. On the customer side, engineers made sure that the motor shaft and motor bearings were dimensioned for the added weight. Open collaboration between Leine Linde and customer engineers made the small, but necessary adaptions easy to manage.

The result of the project was the 793 stainless steel encoder, which is a perfect solution for applications where anodized aluminum is not acceptable. As all 700 series encoders, the 793 is a robust, yet compact incremental encoder designed for use in tough environments.

The 793 stainless steel encoder can be used also for harbor cranes that are subject to salt-water exposure, for applications in chemical and food industries, in mining or in steel plants.

www.leinelinde.com