www.industryemea.com

18

'20

Written on Modified on

Back to basics on computer-on-modules

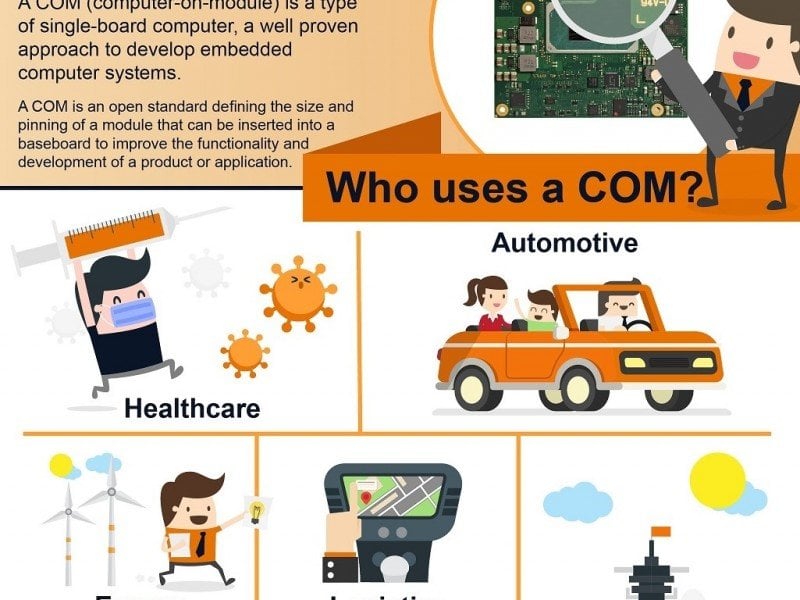

Infographic highlights key differences and benefits of COMs.

Computer-on-Modules (COMs) are widely recognised for their versatility. A COM offers end users a breadth of application capabilities, reduced product development time and can be tailored specifically to meet performance and functional requirements in line with the overall power budget that is available. As products meeting the latest COM standard, COM for high-performance computing (COM-HPC), start to become commercially available in the UK, embedded computing systems provider Recab UK has published an infographic that goes back to basics to explain everything you need to know about COMs.

Building a computer system traditionally involved picking a selection of commercial-off-the-shelf (COTS) circuit boards and components from multiple vendors and integrating them into a bespoke system. The main disadvantage of this approach was it led to complex systems that included components from multiple vendors, with the frequent risk of obsolescence of parts and system redundancy.

“Using a COM dramatically reduces the complexity and offers end users several competitive advantages,” explains Martin Frederiksen, managing director of Recab UK. “With a COM, users can combine multiple elements into a two or three board system approach resulting in a system that is smaller in size, lighter in weight and overall simpler to manufacture.

“COMs are also proven to offer better performance and with fewer suppliers there is less risk of failure. In addition, as COMs are approved not by the suppliers, but by industry groups to drive and sustain performance across industry, they are compatible with multiple vendors, which ensures that our customers’ ROI is protected. If a single component fails or becomes obsolete, replacement can be done efficiently and without costing the earth, keeping the product operational for as long as possible.”

Versatility is one of the primary benefits of COMs. Baseboard size, functionality and the positioning of connectors can all be tailored specifically to meet the product and end use application. As a result, COMs are used in multiple industries including healthcare monitoring and logistics systems. Their use is also prolific in telecommunications and transport, for example to support graphics overlay applications used in aircraft flight displays, as well as in equally critical applications in the defence sector to control multiple devices and capture video streams for syndication.

Choosing the right COM, therefore, depends on the end use application; the performance that is required, combined with available power budget and size of system.

Recab UK is an expert on COM design, manufacture and integration. The company has a vast and diverse range of successfully deployed baseboard designs that can be adapted or reused, in part of full, ultimately reducing risk for customers. Recab is partnered with leading COM module and board suppliers such as congatec and Kontron, as well as market leading component manufacturers to ensure Recab can design systems to meet even the most demanding application requirements.

To view Recab UK’s COM infographic, click here.

www.recabuk.com