www.industryemea.com

16

'13

Written on Modified on

The new F-Gas Directive: What are the immediate solutions?

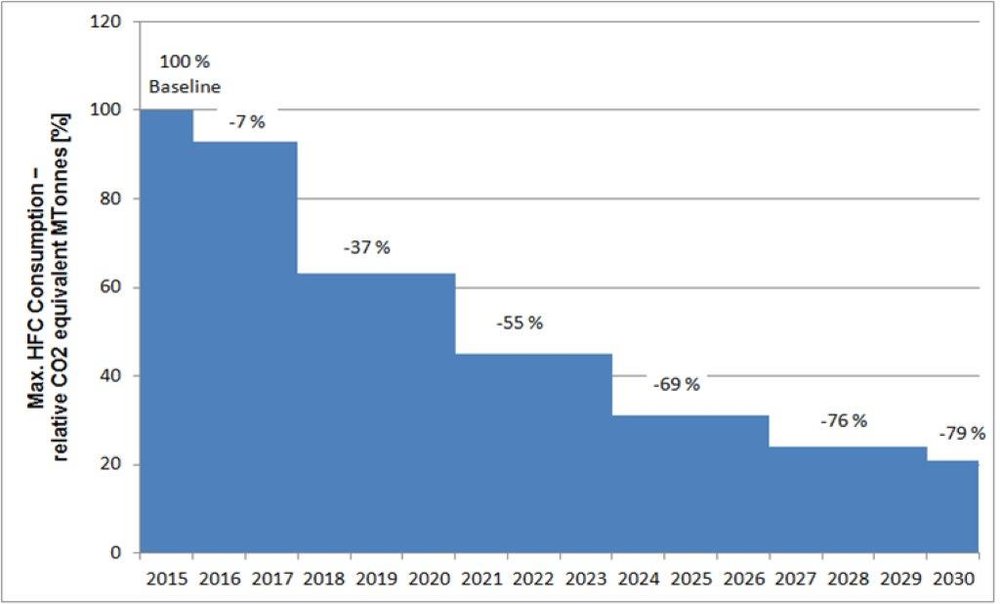

Both the revision to the EU's F-Gas Directive currently under preparation and national refrigerant taxation schemes are prompting manufacturers to turn to water-source solutions in which the refrigerants used are confined to equipment. CIAT adopted a water-source strategy many years ago whereas competing alternatives – like direct-expansion solutions – will quickly have to be abandonned. The environmental consequences of climate change have prompted European authorities to seriously reinforce the EU's F-Gas Regulation. The current version of the regulation, which was enacted in 2006, sets obligations on calculating the weights of both marketed and recovered refrigerants as well as the frequency of checks. It also sets timetables for the phasing-out of non-zero ODP (Ozone Depletion Potential) refrigerants that are destructive to the ozone layer. The revision of the F-Gas Regulation currently under preparation will come into force in 2015. Its aim is to drastically reduce the global warming potential (GWP) of refrigerants currently in use. As from 2015, the sale of refrigerants will be gradually restricted based on their GWP (expressed in kg of CO2-equivalent per kg of refrigerant). The goal is to cut usage by nearly 80% over a 15-year period.

These new timetables have a strong impact on the technological solutions to be implemented in the HVAC sector and require it to look at three major areas.

The first is the marketing of new refrigerant gases. The most advanced solutions to date are as follows. There are three substitutes for R-134a, which has a GWP of 1430 (1 kg of R-134a = 1430 kg of CO2-eq): HFO-1234yf, which has a very low GWP of 7 but requires in-depth redesign of thermodynamic machines; ARM-42, which is a blend of R-134a and HFO and has a GWP of 117; and XP10, another blend of R-134a and HFO and which has a GWP of 631. There are three substitutes for R-410a, which has a GWP of 2088 (1 kg of R-410a = 2088 kg of CO2-eq): DR-5, a blend of R-32a and HFO with a GWP of 490; L-41, a blend of R-32a and HFO with a GWP of 601; and R-32, which has a GWP of 675.

R-32 has a higher GWP because it is a pure HFC refrigerant that, due to its high discharge temperature, induces mechanical stresses. Although the aforementioned blends are the most advanced, many tests are still being carried out to find the best compromise.

The second area is flammability. All the aforementioned new refrigerants are mildly flammable and require the creation of a specific flammability category – A2L. This new category applies to machines in which the refrigerant is confined to the outdoor system (heat pumps). Standards are currently being defined for systems in which A2L refrigerants are circulated inside buildings (system risk assessment and recommendations).

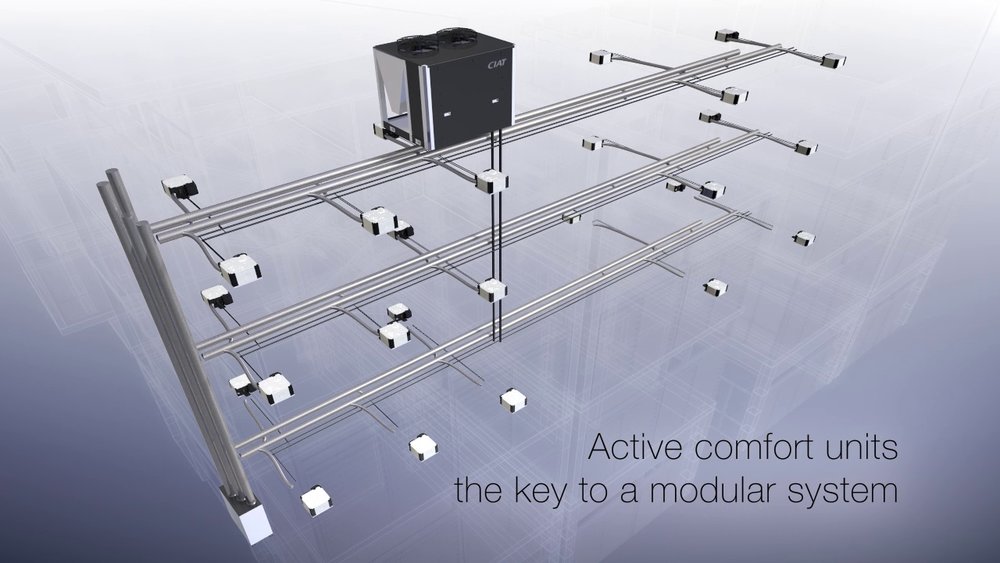

The third area relates to decreasing the volume of refrigerants in systems. Shifting from R-410a (GWP of 2088) to R-32 (GWP 675) alone will not be enough to meet the 80% reduction targets. The first step involves reducing the volume of refrigerants in systems. Extra attention must now be paid to the 'output power to GWP' ratio of systems. This environmental-performance indicator greatly encourages the use of solutions in which refrigerants are confined. A packaged water-source solution in which the refrigerant is confined to the heat pump or chiller requires up to four times less refrigerant than a direct-expansion solution.

Solution in which the refrigerant is not confined

The refrigerant is used as a heat-transfer medium inside the building

Solution in which the refrigerant is confined

Water is used inside the building as the heat-transfer medium

This technical solution is already available and may be used without having to wait for the aforementioned new refrigerants to be placed on the market. An R-410a water-source solution is already as efficient as a future R-32a direct-expansion solution. Furthermore, confining the refrigerant to the outside of a building or in a mechanical room will make it easier to cope with future requirements on flammability hazards.

Regarding national taxation, Spain is the first country in the eurozone to levy a tax on refrigerants that is based on their global warming potential. We currently use R-410a for most of our applications. With a GWP of 2088 kg of CO2-eq per kg of refrigerant and taxed at €0.02 per kg of CO2, the tax levied is €42 per kg of R-410a.

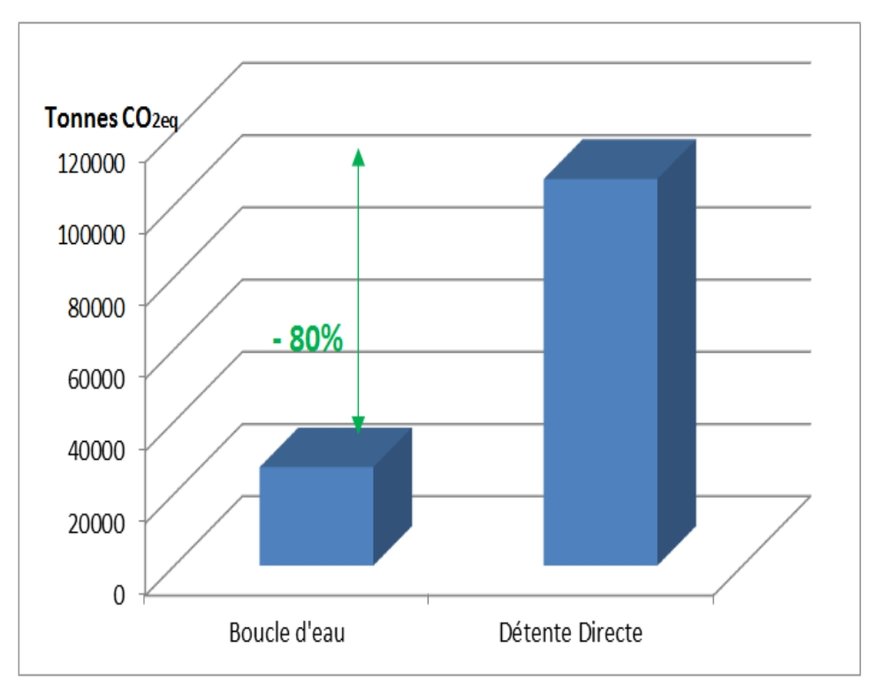

Example of a 1500 m² office building with 75 kW of useful cooling output:

Water-loop solution comprising 1 heat pump and 72 water-source terminal units

Direct-expansion solution comprising 3 outdoor units and 72 HFC-source indoor units

The issue of refrigerants aside, systematically adopting water-loop solutions for commercial buildings alone would enable the F-Gas Regulation's targets for 2030 for this sector to be met.

The tax for a water-loop solution containing 13 kg of R-410a (2.7 kW of cooling per kg of CO2-eq) is € 546. In comparison, the tax for a direct-expansion solution containing 51 kg of refrigerant (0.7 kW of cooling per kg of CO2-eq) is €2,142 for the entire system.