GEA supplies gas cleaning systems for the Fluid Catalytic Cracking Units (FCCU) of two Refineries in Spain

GEA has received two orders for gas cleaning systems from the oil and energy group Compañía Española de Petróleos SA (CEPSA, Madrid, Spain) for their refineries in La Rabida and San Roque.

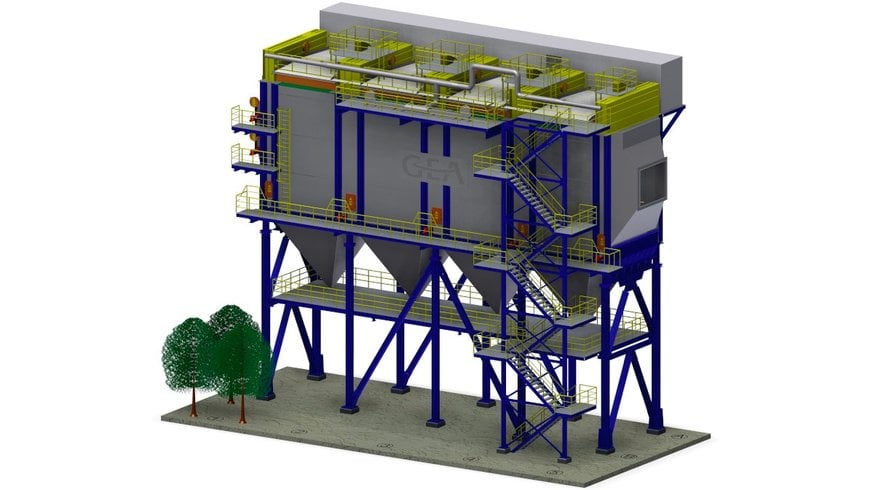

3D visualization of a GEA HESP. (Photo: GEA)

The scope of supply includes the technical planning and engineering, delivery and installation of two Hot Electrostatic Precipitators (HESP) including dust transport and dust storage silos. The existing FCC units at CEPSA will be upgraded with downstream high-efficiency hot electrostatic precipitators for dust capture. GEA’s gas cleaning solution will ensure that CEPSA’s refineries will comply with the emission limits required by the Spanish government from 2024. Commissioning is scheduled for as early as 2023.

GEA's HESPs are robust, reliable and efficient. They can be operated for several years without major maintenance. The customer, CEPSA, wanted to complete the projects with the highest quality in the shortest possible time and therefore chose GEA. GEA has extensive experience in the design and project execution of Hot Electrostatic Precipitators (HESP) for Fluid Catalytic Cracking (FCC) plants.

Hot Electrostatic Precipitators from GEA - the technology

The dust particles suspended in the gas are electrically charged and migrate under the influence of a strong electric field towards the collection electrodes where they are deposited. Accumulated dust layers fall or drop into hoppers arranged beneath the collecting chamber. From this stage, discharge and further transportation is carried out by mechanical or pneumatic devices respectively. An essential factor in achieving maximum collection efficiency is an even distribution of the gases over the entire cross section of the precipitator. This is ensured by correct design of the precipitator inlet transition and the installation of specially designed gas deflection and distribution plates.

In accordance with the required collection efficiency of the hot electrostatic precipitator the dust-laden gas flows through several sequentially arranged electrical fields. Regular cleaning of the electrodes is ensured during operation by state-of-the-art tumbling hammer cleaning devices.

Features of GEA HESP for FCC

- Efficient separation of dust at temperatures up to 450°C.

- Even flow distribution achieved by specially designed gas distribution plates.

- Use of optimized collecting electrodes

- Electrode rapping with reliable and robust tumbling hammer system

- Reliable insulator design for long-term operation

- High voltage supply by transformer/rectifier-sets including controllers

- No ammonia injection needed