www.industryemea.com

09

'21

Written on Modified on

The Strong and the Soluble: What Will You Make with the New Additions to Our Portfolio, Tough PLA and BVOH?

Thanks to our ongoing collaboration with Mitsubishi Chemical (MCPP) and BASF, two new standard 3D printing materials have arrived at BCN3D. Tough PLA is impact resistant, stiff and easy to use. BVOH provides fast hydro solubility, use as a support material and wide compatibility with most filaments in the BCN3D portfolio.

Here at BCN3D, we believe that the future of 3D printing is bright, so we are constantly researching, testing and creating in order to propel its advancement. Our recent endeavours with MCPP and BASF have produced two new materials to add to our portfolio: Tough PLA for tooling and end-use parts and BVOH for water-soluble supports.

“We are very excited to have two of the major chemical companies in the world as close partners. Their expertise in the industry and our combined capabilities in co-developing new solutions have proven to be essential.” – Eric Pallarés García, CTO at BCN3D.

What is Tough PLA?

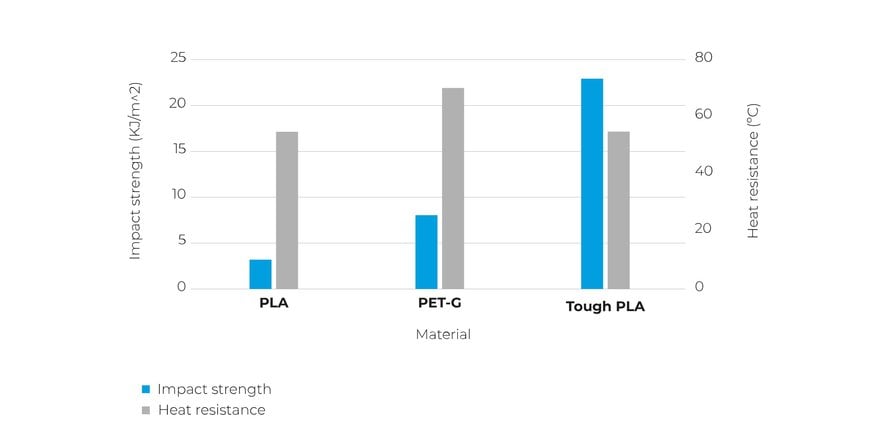

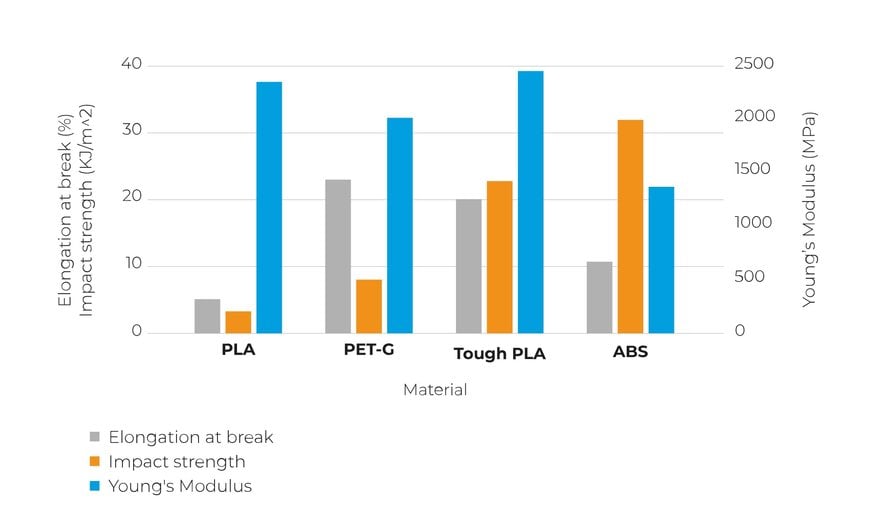

You may be familiar with regular PLA (polylactic acid), the most popular 3D printing material that provides stiffness, a variety of colours and ease-of-use. Tough PLA possesses the same qualities but differs in the fact that (you guessed it) it is tougher and stiffer.

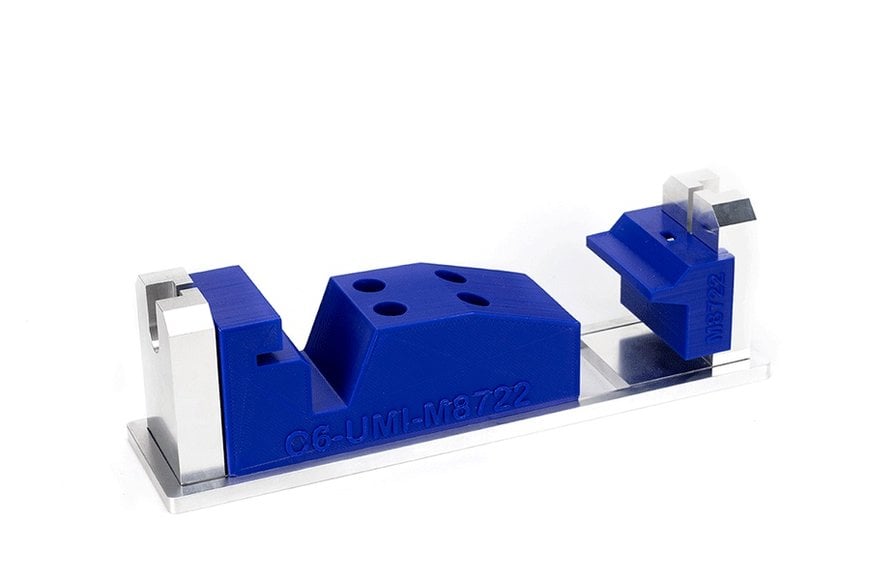

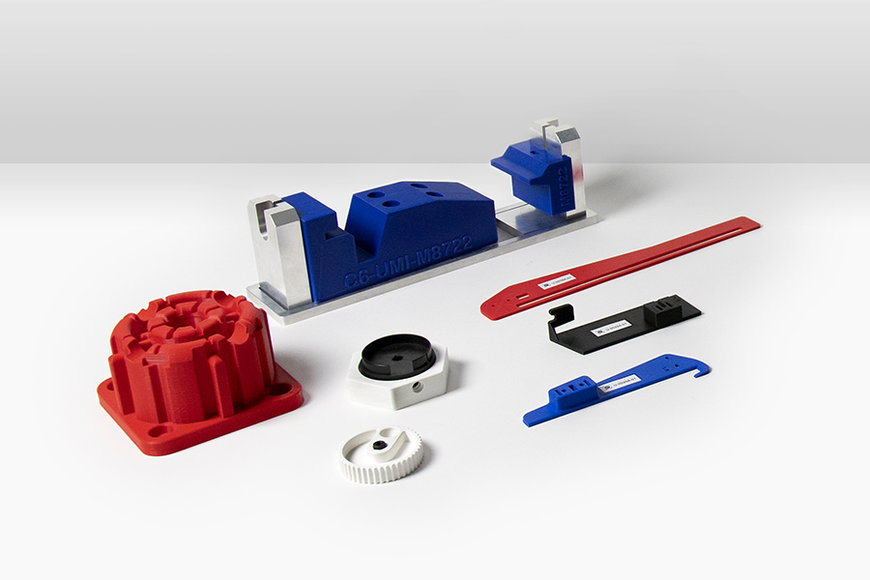

Tough PLA is engineered for its high impact and strength, similar to ABS, and with a stiffness akin to PLA. It is a plug and play material, shows excellent results in layer adhesion and has a very good surface quality. Tough PLA can also be easily printed using many different temperatures with no warpage or shrinkage.

A good balance between temperature resistance and toughness

What can it be used for?

For functional prototyping, Tough PLA’s easy printability and competency in layer adhesion works well. Tough PLA is perfect for both manufacturing aids and manufacturing tools because of its resistance to high impact and industrial feel, and its ability to perform as a standard material with more demanding properties.

It works as an alternative to ABS for large prints as, in comparison, Tough PLA is stiffer, presents much less warping issues and is more 3D printing friendly as it doesn’t need an enclosed printing environment or emits any fumes which would require filtering.

Tough PLA will initially be available in colours black and white, with red and blue references available shortly.

“Tough PLA is really a great alternative to ABS and I would recommend it for applications that require high impact resistance, easy printing and excellent surface quality.” – Álvaro García Sabater, Product Manager

Ideal for manufacturing stiff parts

What is BVOH?

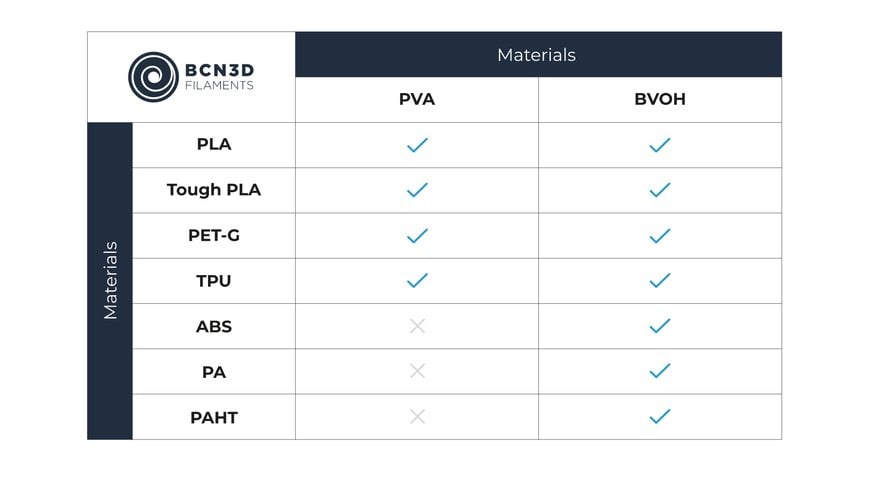

BVOH (Butanediol vinyl alcohol copolymer) is a thermoplastic optimized for the FFF manufacturing process. Its main advantage is its incredibly fast dissolution. This water-soluble material is easy to remove from inside small parts and reduces clogging issues as a result. It is compatible with PLA, Tough PLA, PET-G, TPU 98A, ABS, PA and PAHT CF15. Highly hygroscopic, make sure to store your BVOH in a sealed container to prevent moisture absorption.

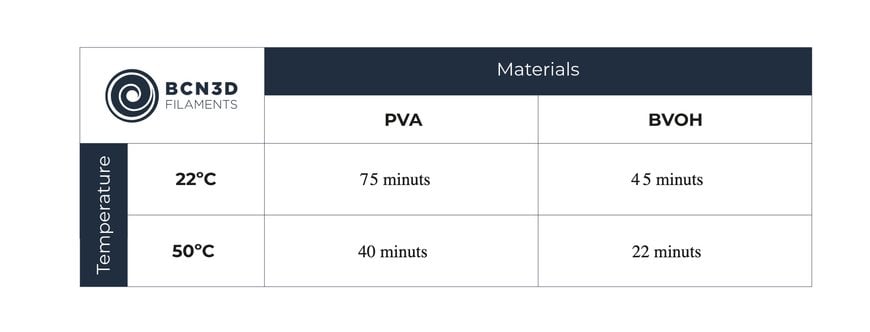

Dissolution time BVOH vs PVA

Wide compatibility with BCN3D Filaments portfolio

What can it be used for?

BVOH is ideal for water-soluble supports for partially enclosed cavities and complex geometries, or even sacrificial moulds. When dissolving, the higher the water temperature, the faster the process. This makes it a great way of printing temporary support materials for complex geometries, such as structures with overhangs. It gives a smooth finish on functional prototypes and has excellent surface quality. With BVOH, movable mechanisms and hollow parts are also achievable, as well as multi-component models.

“BVOH is a complementary support material (PVA & BVOH) and I would recommend it for parts that need water-soluble supports, taking the potential of IDEX architecture; but also when a wider compatibility with our material portfolio is needed.” – Álvaro García Sabater, Product Manager.

Our ever-growing portfolio

This addition of Tough PLA and BVOH brings the number of materials under our belt to a total of 9 (encounting). Both Tough PLA and BVOH are compatible with our new portfolio of the Sigma series (Sigma D25) and the Epsilon series (Epsilon W50 and Epsilon W27), as well as our old portfolio containing the Sigma and Sigmax. Just as with our printer series, we want to make printing accessible for all our users, from desktop to the workbench.

ww.bcn3d.com