www.industryemea.com

20

'21

Written on Modified on

New Rexroth robotics kit for mobile robots reduces engineering effort

Software and hardware modules from Bosch Rexroth accelerate time-to-market for OEMs.

For the seamless interaction of mobile robotics and IT, Bosch Rexroth presents a modular robotics kit consisting of software and hardware components. The kit currently includes an infrastructure-free localization solution, as well as a module for route planning and a standardized drive, both currently in the pilot stage. The components can be purchased independently or in combination. With this kit, developers significantly reduce their engineering effort for a wide variety of mobile robots. Open interfaces to IT and to any industrial control system as well as prepared safety functions up to performance level (PL) d reduce the time to market and the setup time at the customer site.

With the software component ROKIT Locator from Bosch Rexroth, which won the IFOY Award in 2020 and has got new features, mobile robots such as Automated Guided Vehicles (AGV) determine their position using an independently generated map of their surroundings. For the commissioning of the component, users require neither expert knowledge nor concrete constructional devices. The ROKIT Locator generates a map of the surroundings during a reference run and shares it with other vehicles connected to the fleet via a server. The new reference alignment function can link this map to an existing layout of the environment stored in IT systems. The different maps are synchronized through common reference points.

This allows to clearly locate and approach the storage spaces saved in the IT system. If additional hardware is required, Bosch Rexroth offers the ROKIT Locator.Box, a combination of the Locator software, the ctrlX AUTOMATION operating system and an industrial computer. The new software component ROKIT Navigator takes over the route planning on the basis of the Locator map and automatically takes different chassis and drive systems into account. The first pilot customers are currently testing the ROKIT Navigator in real operation. Depending on the size and steering characteristics, the component gives driving commands adapted to the vehicle, thus further reducing the engineering effort for OEMs. Both software components are compatible with numerous industrial controllers and laser sensors from different manufacturers.

The ROKIT Motor is also in the pilot stage. This ready-to-install drive module for payloads of up to one ton adds powerful standard hardware to the modular system for mobile robots. The ROKIT Motor consists of an 800 W electric drive, a gearbox, brake and a pre-programmed control system. Functional safety up to PL d has already been prepared and documented.

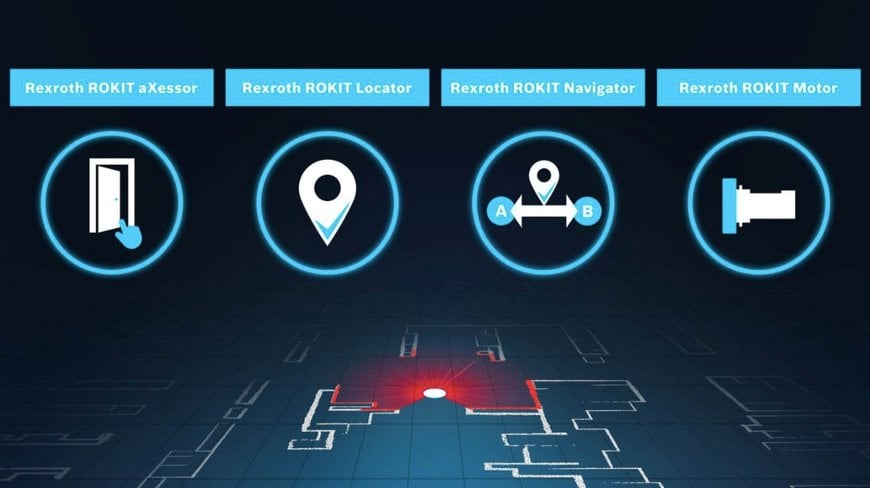

Additionally, the intuitive and graphical user interface ROKIT aXessor allows the access to all ROKIT components by connecting to their APIs. Based on a 3D game engine, the ROKIT aXessor creates an easy and user-friendly operation.

The components ROKIT Locator, ROKIT Navigator, ROKIT Motor and ROKIT aXessor automate mobile robots for manufacturing and intralogistics in industry as well as for applications in retail and, for example, use in hospitals. The modular system is to be expanded in the future to include further mobile robotics modules.

www.boschrexroth.com