Bosch Rexroth performs handling tasks mechatronically – the quick and easy way

Smart Function Kit for Handling drastically reduces engineering effort and realizes commissioning with just a few clicks.

With the modular Smart Function Kit for Handling, Bosch Rexroth offers users a mechatronic subsystem for handling tasks which can be used immediately.

- Cost-effective multi-axis solution from a single source

- Fast commissioning through automatic drive parameterization

- Rapid integration and value creation

Intelligently designed multi-axis machines - implemented quickly, conveniently and cost-efficiently like never before: Bosch Rexroth now meets this requirement with the new one Smart Function Kit for Handling. After this Smart Function Kit for pressesand joining, the linear technology experts are thus expanding the Smart MechatroniX solution platform with a second predefined and intuitively operated subsystem. With the new mechatronic kit, users can achieve enormous time savings in the engineering of multi-axis machines - for a quick return on investment with fully digitized handling solutions.

The wide range of applications for the new Smart Function Kit includes, for example, the areas of production handling, machine assembly and packaging. Pick-and-place tasks can also be implemented quickly and cost-effectively - as a Cartesian multi-axis system for packages of different sizes, weights or formats.

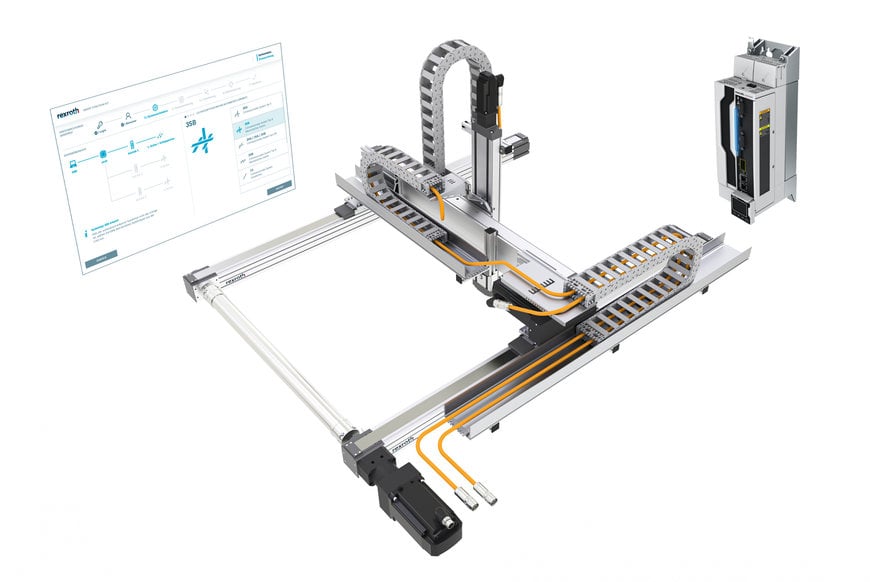

Everything in one package: a preassembled multi-axis system including a motor, cable and all attached parts as well as a suitable ctrlX servo drive including a controller.

The plug-and-produce approach cuts the time required significantly

The new planned subsystems for multi-axis applications offer measurable advantages over conventionally created solutions. Above all, these consist in significant time and cost savings, from the design to the final configuration to operation. The plug-and-produce approach significantly reduces the time required for commissioning.

Well-designed multi-axis solution from a single source

The Smart Function Kit for Handling can be operated easily and intuitively using the LinSelect softwareselect and lay out. With just a few clicks and minimal engineering effort, interested parties can see exactly which systems are suitable for their requirements. The data from LinSelect can then be transferred directly to the configurator and the system can be fully configured. You can also order directly from the Rexroth eShop. This end-to-end tool chain not only saves time, it also reduces sources of error, for example through multiple entries of data in different tools.

In addition to the pre-assembled multi-axis system including motor, cables and all add-on parts, the appropriate ctrlX drive controller including control is included in the package. Engineering and runtime apps are already preinstalled.

The preinstalled software can be used on various end devices and can be operated immediately with no need for programming knowledge.

Fast commissioning through automatic drive parameterization

The pre-installed software offers great savings potential in terms of time and effort when commissioning and integrating the subsystem. The entire system is parameterized automatically. The intuitive, graphic operation via a web-based HMI also shortens installation times. Ready-made function blocks enable the process to be easily programmed. Expensive external programming is no longer necessary.

Open interfaces also guarantee the connection to different controls and thus enable larger, interlinked handling tasks. The software can be expanded via apps and has IIoT data interfaces via OPC-UA and ResT programming interface REST-API as well as a firewall-compatible security architecture.

www.boschrexroth.com