Robotics 101: A Complete Guide to Warehouse Robots by Application

It is no secret that the demand for mobile robots is growing and that the warehousing industry plays a huge role in this. However, choosing the right robot for the right application is definitely not an easy task.

With the growing demand for mobile robots, many different types of robots are popping up in the industry for all kinds of use cases. This does not make it any easier for warehouses to choose the right robots for their facility. In order to make the decision-making process a little bit easier, Meili Robots has created a guide to warehouse robots based on application.

The guide covers:

- The difference between AGVs and AMRs and their navigation technologies

- Warehouse robots that transport products and freight

- Warehouse robots that assist with picking, packing, sorting, and storing

- Warehouse robots for inventory management

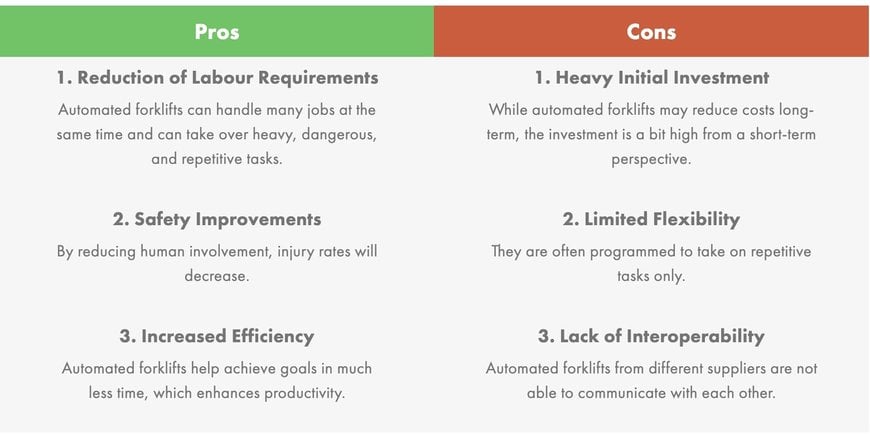

As shown above, Meili Robots’ guide to warehouse robots has divided the robots into three main categories of applications: 1) transportation; 2) picking, packing, sorting, and storing, and; 3) inventory management. However, some of these robots can, in fact, be used for more than one type of application. To paint a clear picture, the guide includes common product specifications, price estimates, and pros and cons for each robot type.

Automated Forklift Pros and Cons

Use Cases of AGVs and AMRs in Warehouses

While looking at warehouse robots, we can distinguish two main types of mobile robots: Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). Whereas AGVs typically move around the facility following fixed routes using rail navigation, magnetic tape navigation, or wire-guided navigation, AMRs, as the name suggests, move around the facility autonomously. They do so using technologies such as LiDAR as well as label-, laser-, and vision-based navigation.

AGVs are most commonly used for the transportation of raw materials such as paper, plastic, rubber, steel, and metal. AMRs have much more flexibility and are often used for repetitive tasks that were previously carried out by human workers. For example, a worker who fills the shelves in a warehouse could summon an AMR and easily send it on its way again to transport goods to the desired destination in the most efficient way.

www.meilirobots.com