www.industryemea.com

30

'21

Written on Modified on

Machine tool builder benefits from NSK motion control solutions

Euromac, a global specialist in the design and manufacture of punching and bending machines, is benefitting from NSK ball screws, linear guides and bearings in two high-profile recent projects. In fact, Euromac has been taking advantage of NSK motion control technology since 1995 as part of a long-standing and highly successful partnership.

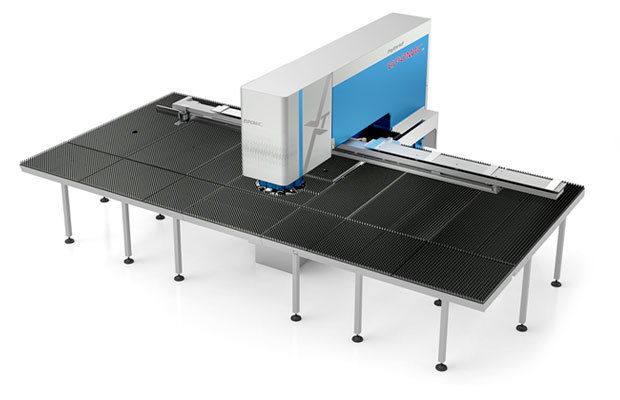

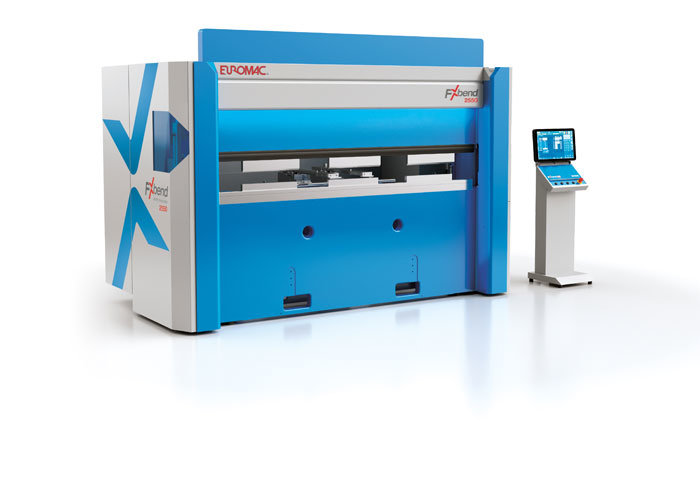

From its headquarters in Italy, Euromac tailors machines to meet demanding customer requirements; the combination of state-of-the-art technologies and unique concepts assures users of advanced, productive and competitive products at all times. Continuous improvement and innovation is a core company ethos and represents the reason why Euromac has been able to expand its worldwide presence and achieve impressive growth since its formation in 1986.Among the latest Euromac machines to benefit from NSK motion control technologies are: the FX Bend 2550 new-generation electric press brake with 50 or 60 tonne press force, 2550 mm bend length and six-axis back-gauge; and the new-generation XT punching machine (hydraulic, hybrid or electric) with 1500 x 3000 mm capacity and a new reinforced frame. In both applications, NSK is the main supplier of ball screws, linear guides and bearings.

The Euromac XT sets the bar for innovation in the punching machine arena by being available in hydraulic, hybrid and electric variants. In each type, Euromac uses a different way of moving the main punching axis. In the electric version, for example, the technology holds its own patent. Here, acceleration of 90 m/s2 and stroke of sometimes less than 10 mm, means that impact load is a constant issue.

With this thought in mind, there is a clear need for high-performance, robust and reliable linear motion products. For the main punching axis on the electric Euromac XT, NSK therefore proposed its HTF SRD series ball screw with S1 ball spacers featuring grease-retaining attributes. These ball screws also make use of a special material named Tough Steel. Providing the perfect complement to the HTF SRD ball screw is the RA series linear guide with high acceleration capability.

HTF SRD ball screws take advantage of an innovative end deflector recirculation system to achieve ultra-high speeds of up to 3 m/s, offering shorter cycle times and higher productivity to end users. Importantly, this high-load ball screw ensures good rotational balance, with no run-out of recirculation components, while the optimised (smooth) ball circulation methodology reduces noise by half compared with conventional systems.

NSK’s RA series of low-friction, high-load capacity roller guides provide high rigidity to deliver the traverse and repeat accuracy necessary in machine tools such as the Euromac XT. This capability results from, among other things, special restraining and deflecting components, as well as the use of rollers with the largest possible diameter and a slightly crowned surface to minimise vibration during rotation. The carefully matched spacing and restraint technology of the roller bodies also produces very high uniformity of the displacement forces that occur.

After a year of comprehensive and successful testing, Euromac recently commenced volume production of its XT punching machines, exemplifying how the performance and quality of NSK linear motion products, together with proven technical support, can benefit innovative machine tool builders.

1) The new Euromac XT punching machine uses high-performance, robust and reliable linear motion solutions from NSK. Photo: Euromac

2) The Euromac FX Bend 2550 new-generation electric press brake also benefits from NSK motion control technologies. Photo: Euromac

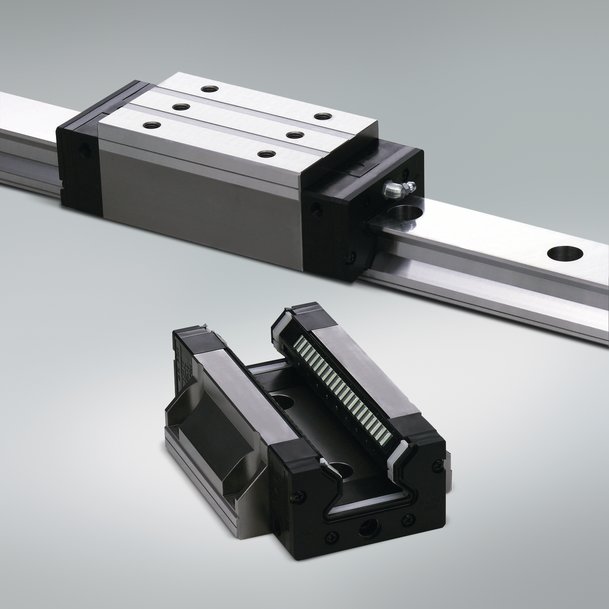

3) NSK HTF SRD ball screws take advantage of an innovative end deflector recirculation system to achieve ultra-high speeds. Photo: NSK

4) NSK’s RA series of low-friction, high-load capacity roller guides provide the high rigidity necessary in machine tools such as the Euromac XT. Photo: NSK