www.industryemea.com

06

'14

Written on Modified on

Intelligence Inside: The New FieldConnex® FieldBarrier

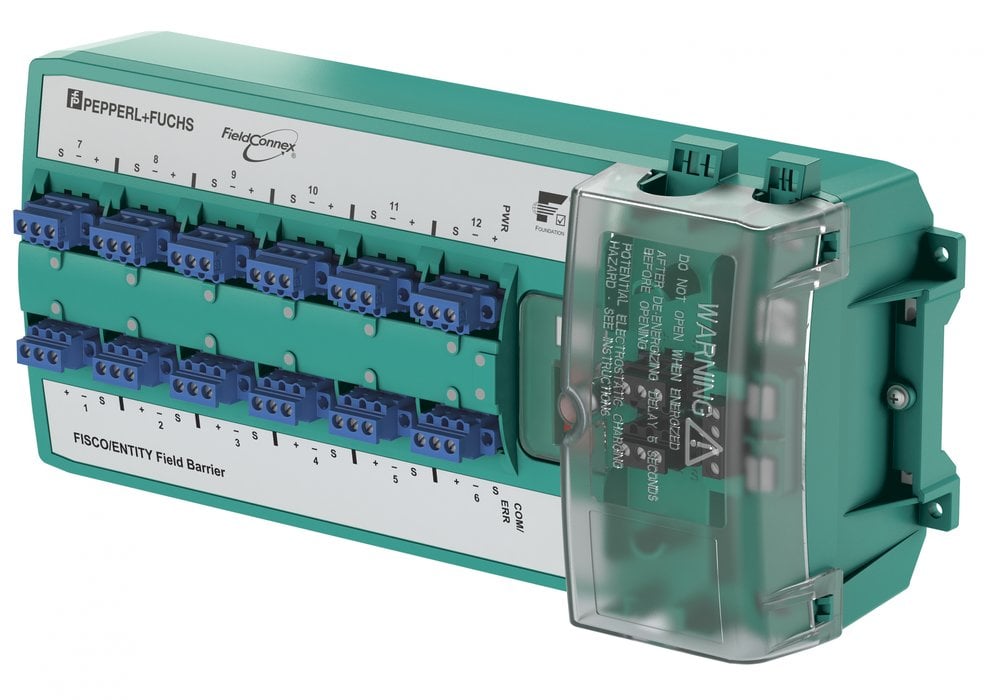

Intelligent Fieldbus from Pepperl+Fuchs is synonymous with a generation of components that brings diagnostic capabilities into the field. The new FieldConnex® FieldBarrier is the perfect addition to this concept of uncompromising availability. It includes twelve outputs with diagnostics and monitoring. The FieldBarrier comes with innovative technical features that offer reliable protection against typical fault scenarios to ensure maximum reliability.

The new component is the first to allow monitoring of the physical layer at each FieldBarrier output. This enables gradual changes in the installation and faults in the control room to be reported. This monitoring function ensures an even higher degree of transparency and covers a significant gap in the monitoring process as it proactively identifies maintenance requirements. Another feature is the sophisticated load management. The twelve outputs start sequentially, reducing the load on the power supply from the inrush current. What's more, if the segment current reaches critical levels, automatic load-shedding of less critical nodes is activated in order to safeguard against failure of the entire segment.

Photo: The FieldBarrier with twelve outputs and a compact design

This package of integrated intelligence is completed by the FieldBarrier self-monitoring function, which can transmit alarm signals to the control room. These innovative features do not require any engineering. The FieldConnex FieldBarrier is the perfect addition to diagnostics-enabled intelligent fieldbus components and is another key step toward achieving the goal of 100 % availability.

Author: Andreas Hennecke, Product Marketing Manager, Process Automation division