www.industryemea.com

21

'21

Written on Modified on

NEW: THE STAUFF FORM EVO TUBE FORMING SYSTEM

Increased Level of Efficiency and Versatility as the Result of Continuous Optimisation.

The STAUFF Form tube forming system was first presented in 2015. Since the beginning it has undoubtedly been one of the most efficient solutions available on the market for connecting metric tubes. In addition to its simplicity, it convinces with a high degree of safety, reliability and reproducibility.

With STAUFF Form EVO, STAUFF now presents the latest generation of the tube forming system, which is characterised by an increased level of efficiency and versatility as a result of continuous optimisation.

STAUFF Form EVO has been designed as standard for seamless cold-drawn precision steel tubes as well as stainless steel tubes with dimensions between 6 x 1.5 mm and 42 x 4 mm in the Light Series and between 6 x 1.5 mm and 38 x 6 mm in the Heavy Series.

If required, parameters for alternative materials are available upon request and can be added by the manufacturer or via the optional cloud connection module integrated in the machines.

Key Benefits of the STAUFF Form EVO Tube Forming System Design

- Based on standard components including the standard union nut of the STAUFF Connect product range according to ISO 8434-1 – No duplicate storage

- of similar stocking of similar components with a correspondingly high risk of confusion

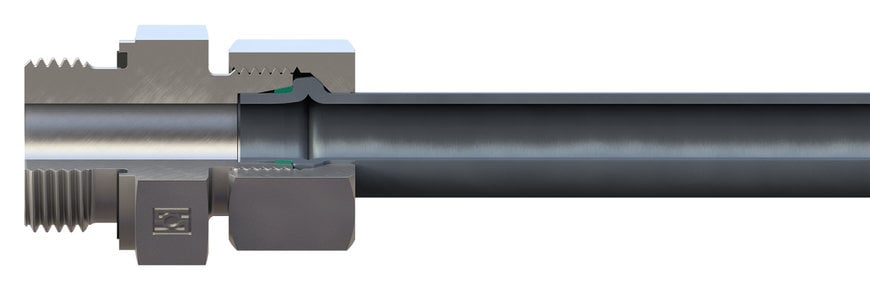

- Positive-locking connection with an elastomer sealing with a particularly large cross-section to provide secure and permanent sealing even in the event of unfavourable tolerances

- Sealing of the only possible leakage path primarily via the STAUFF Form EVO sealing ring as well as the secondary, face sealing

- Preservation of the flow behaviour through the optimised shape of the formed tube end.