www.industryemea.com

28

'14

Written on Modified on

Cutting-edge laser machining. Latest machine-generation with cost-efficient mechanical transmission designs

Based in Chennai, Proteck was established over twenty five years ago and is now one of India’s leading production machinery suppliers; distributing, supplying and manufacturing a wide range of printing machinery, machine tools, metal cutting & forming equipment and CAD/CAM software throughout its home market and in more than 20 countries world-wide. Its manufacturing subsidiary, Proteck Precision has a young, dynamic and highly qualified engineering work-force that develops and produces exciting new economy solutions for the fast growing Indian manufacturing industries as well as providing competitively priced machinery that is exported beyond Asia. The technology driven company has styled its production, quality control and engineering logistics departments on a European model and has two very modern manufacturing facilities in Chennai complete with state-of-theart CAD/CAM, MRP systems and the latest ISO accreditations.

Proteck Engineers have had extensive training at Kollmorgen’s Ratingen facility. Today, as Proteck develops its own special purpose laser cutting and CNC machine tool range, Kollmorgen is very firmly established as a manufacturing partner. “Our latest generation laser profiling and machine tools have developed from our more than two-decade experience in supplying and supporting machine tool technologies from our partners, as well as from our increasing in-house design and manufacturing capability.” says Mr. K. Bala, Proteck’s Managing Director, “For both of these important factors, we can count Kollmorgen as a major technology contributor and a valued partner.”

The Proteck range

Proteck’s evolution to manufacturing its own machines began with high specification CO2 equipped 3-axis laser cutting machines with flying optics that cater to a wide range of flat sheet material. These small footprint machines originally included cast-iron beds and single lower axis geometry that allowed open three-side access for flat sheet sizes around 2.5 x 1.5 metres. Bosch Rexroth or Siemens CNC controller options fully integrated with Proteck’s highly developed MetaCAM CAD/CAM software allows ease of use for all types of sheet metal cutting. As a development from this machine Proteck introduced a ‘Plug and Play’ model for job and fabrication shops that included all of the features of the previous machines but used a much lighter and lower cost welded frame construction. The technology leader had begun its ground-breaking marketing concept that a laser cutting machine should be no more complicated than an office laser printer.

As part of this continued initiative, its designers looked hard at the transmission mechanics. Precision ground ballscrew cost for a 2.5 metre travel range is expensive and the single-axis/single-screw design with its overhung load requires more sturdy and costly linear motion guide bearings for adequate support. Furthermore, to maintain a good dynamic performance, the ballscrews need to be large in diameter to allow high rotation speeds – which increases servo motor and servo drive size. With the need to produce even longer travel machines that could provide larger flat sheet work, Proteck and Kollmorgen EU began to address some central questions:

• How to maintain the +/- 10 micron bi-directional repeatability performance and up to 110 m/min max linear speed, required of the machines?

• How to reduce the power requirements and provide increased efficiency?

• How to further drive down powertrain component costs?

The result was the introduction of an innovative rack and pinion drive system for the long-travel lower axis of the machine for a new 3-axis bridge laser machining centre which includes two synchronised lower X-axes supporting a gantry Y-axis, and a vertical Z-axis..

Rack and pinion with direct drive motor and innovative preload

The initial conception looked at linear motor technology for the long-travel dual synchronised X axis but the cost for this was prohibitive for the market sector Proteck targeted for the machine. Proteck’s cost effective rack and pinion design concept was thus developed with the awareness that backlash and repeatability performance would need to be achieved using a novel approach. The special preload mechanism was realised by mounting the pinion and its motor on an eccentric pilot circle and a gear tooth geometry that allowed full face gear contact and in-situ adjustment to minimise lost motion and hysteresis. This performed more than adequately at the point of the actual rack and pinion face - but when combined with a standard rotary servo motor which required a planetary gearbox to develop the torque required to drive the load - the gearbox backlash, albeit relatively small, proved prohibitive. The answer was to design the pinion-to-rack transmission around the Kollmorgen KBM series direct drive motor.

Directly coupled

The KBM’s separate rotor and stator packages are now supplied in kit form and directly mounted on the machine by Proteck within their own bearing system and protective cover, with power and encoder connectors built-in. The mounting arrangement directly couples the large diameter pinion shaft to the rotor as a single solid assembly, restricting lost motion and potential unwanted harmonics that a flexible coupling may give rise to. The resulting design has been field proven for extremely low backlash and has a dynamic and throughput specification which is very close to linear servo motor performance. The rack and pinion system is also very resilient to debris and does not require the degree of protection that a linear motor system would necessitate for a laser machining environment.

With the success in performance and reliability that Proteck has experienced with the KBM and AKM motors, other developments have followed.

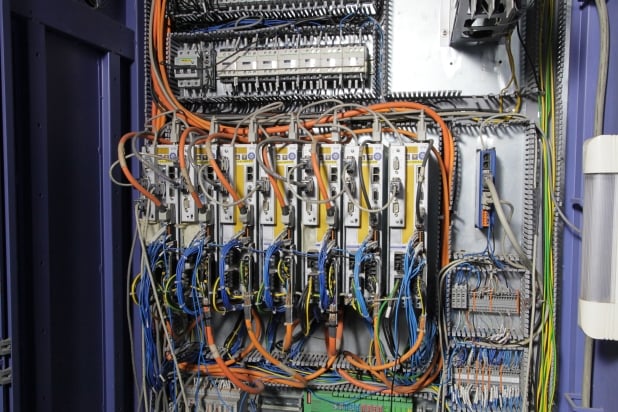

Simply put, the Proteck rack and pinion system, combined with the Kollmorgen direct drive KBM motors has less parts, is more energyefficient and delivers higher speed and accuracy, reducing the backlash and lost motion to well below the desired specification.As an intrinsic part of the design, Kollmorgen S700 servo drives with their multifeedback capability are used with both resolver feedback, mounted on the KBM motor for commutation, and magnetic linear scales for the position loop. The feedback protocol is SSI absolute, EnDAT or alternatively BiSS to suit a choice of CNC controllers with set-up and monitoring via EtherCAT which is integrated in all S700 drives. Many optional features of the advanced servo drive may be included in the machine specification.

These include STO (Safe Torque Off) for SIL 2 and 3 safety standards, and Ethernet connectivity for set-up and monitoring. EtherCAT is also available and will be integrated in future machines for axis synchronisation.

The KBM motors offer a great deal of freedom to configure the servo axes in a spaceoptimized

way due to their variable, modular design.

With a maximum sheet size of 3.1 x 1.6 metres, the new generation flat sheet cutting machines also use Kollmorgen AKM series rotary servo motors with Micron™ series planetary gearheads for the Y axis as well as the Z axis with a brake fitted. For complete compatibility, S700 drives are used throughout the machine. This machine will also benefit in the future from a cost-op¬ti¬mised CNC con-trol so¬lu¬tion from the German cutting machine specialist Eckelmann - who also works closely with Kollmorgen EU.

Direct drive offers further advantages

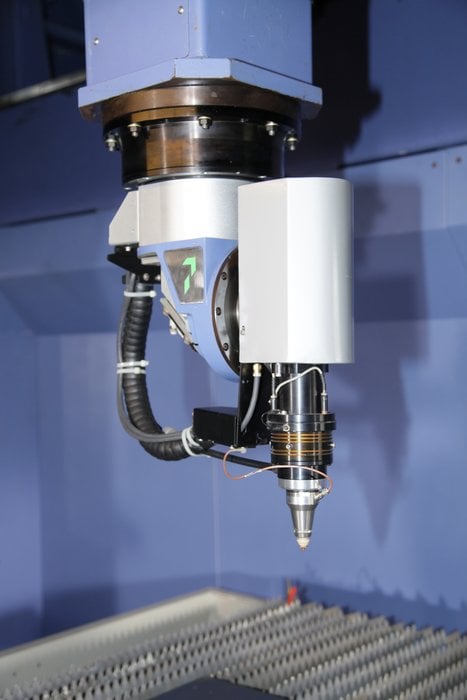

Developing on from the flat bed, 3-axis bridge gantry machines Proteck’s latest laser cutting machine, the Sl 2530, is a massive 7-axis ‘walkin’ machining centre which includes an advanced flying optics head design that provides laser cutting of vertical and angled sides of formed workpieces. Large three-dimensional fabricated sheet metal workpieces are fixed to a stationary central table and the multi-rotational laser head is guided to always maintain the optimum perpendicular angle for perfect cutting. KBM direct drive motors with Proteck’s innovative rack and pinion mechanism are used for main horizontal axes of the machine which cover an area of 1.6 x 3.3 x 0.7 metres. Furthermore the hollow shaft KBM motor is also used as the main drive for the multi-rotational flying optics system – allowing feed-through of the laser delivery and focussing system whilst maintaining the flexibility and precision to provide completely synchronised twin rotary axes featuring nX360 degrees and +/- 135 degrees rotational strokes. The machine also uses a complement of AKM servo motors on other axes along with matching S700 drives, allowing Proteck and its customers to reduce spares and inventory costs.

Servodrives S700 are place with less space in the cabinet.

Other developments and future projects

With the success in performance and reliability that Proteck has experienced with the KBM and AKM motors, other developments have followed. The BMT 125 is an advanced Siemens CNC controlled table-type

horizontal boring and milling machine which has recently benefited from the replacement of standard rotary servo motor drives and backlash-prone gearboxes with KBM direct drive motors. Directly coupled to X, Y and Z axis ballscrews, the improved transmission system has less parts, more efficiency, uses less energy and enables higher speed and accuracy by removing the backlash induced by the gearbox. Once again, Proteck install the rotor and stator components into its own bearing design, complete with a protective housing that takes care of the electrical connections.

In conclusion, the fast moving growth in the BRIC economies is driving the well-placed Proteck to continued success, and more machines that will include the benefits of direct-drive technology from Kollmorgen. In

fact, development time is also being reduced. “With fewer parts to design into our machines and the standardisation of Kollmorgen’s field proven direct-drive technology, we have reduced our engineering time,” says Mr. K. Bala, “in this way we can take products to market more quickly - and with fewer components, improved precision, better machine reliability and higher efficiency, we can steal the march on our competitors and gain more market share.

The KBM’s separate rotor and stator packages are now supplied in kit form and directly mounted on the machine.

Author:

Alexander Hack,

Market Development Manager,

Kollmorgen, Ratingen