www.industryemea.com

23

'22

Written on Modified on

Ensuring the sustainability of joining technology

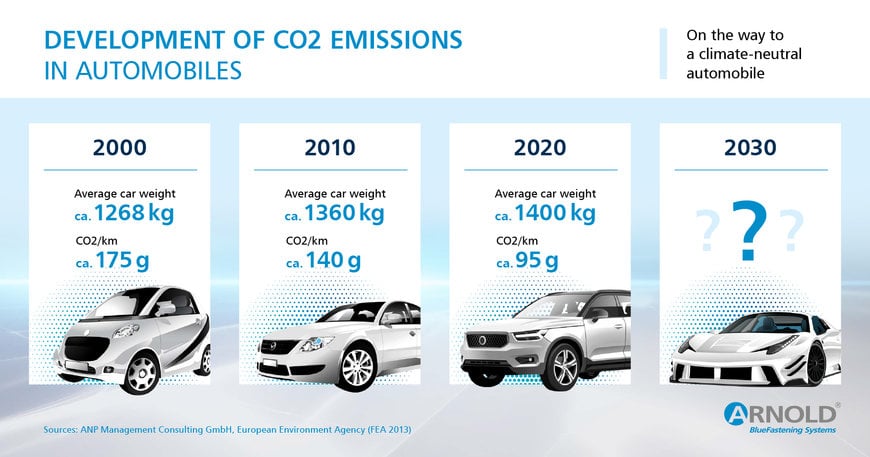

If we look globally at developments in the automotive industry, we can see that the weight of new passenger cars and light commercial vehicles in Europe has risen constantly in recent years from approx. 1,268 kg in the year 2000 to 1,360 kg in 2010 and approx. 1,420 kg in 2020. The trend toward more hybrid and electric vehicles is likely to intensify this development, because an electric vehicle weighs on average 300 kg more than a vehicle with a conventional engine due to the weight of the battery alone.

Despite increasing vehicle weight, CO² emissions from passenger cars in Europe need to be further reduced to be able to reach climate protection targets.

However, due to the optimization of fuel consumption and innovative new powertrain concepts, significant reductions in CO2 emissions have been achieved, from about 175 g CO2/km in the year 2000 to 140 g CO2/km in 2010 and 95 g CO2/km in 2020. It is essential that this trend should continue if the climate protection goals for the next few years are to be attained.

In this context, the issue of sustainability is a major priority for the German fastener manufacturer ARNOLD GROUP. Alongside e-mobility, internationalization, lightweight engineering and digitalization, it is one of their five defined strategic thrusts.

The company's experts are capable of determining the specific carbon footprint of each product by examining the whole value chain and cumulating the emissions of all supply chain members. This means that companies that are downstream in the supply chain add the emissions of their suppliers via the products and services they purchase and then pass these on to their customers, added to their own CO2 emissions.

Thanks to ACO2-Save and the associated changes to production technology, German CO2 reduction targets were achieved and the CO² emissions caused by this screw during production were reduced by as much as 45 percent.

ACO2-Save offers many different ways of reducing CO2

Against this background, Arnold Umformtechnik has launched the ACO2-Save initiative. (The A here stands for Arnold.) The program provides active support to customers in reducing CO2 emissions by designing and using fasteners and cold-formed parts in a sustainable manner. Already in the product development phase, an accompanying CO2 calculation is carried out. When a customer requests Arnold to make a part, the product carbon footprint can be determined using a specially developed CO2 calculator, after which optimization can be carried out jointly. The objective at the end of the development process is to have a technically high-quality product that is both cost and CO2-optimized.

The design process includes the following steps: CO2-optimized engineering through digital forecasting tools, analysis of CO2 optimization by potentially making a change in the production technology or in the joining technology, and the use of innovative joining elements or systems.

And it is precisely this ACO2 Save approach that works, as shown by this example: A special screw made of aluminium with a volume of 8,733 mm3 and a weight of 23.58 g per piece was previously produced by traditional machining. For production, a turned part blank was used that had an initial volume of 25,630 mm³ and 69.2 g per piece. After an ACO² Save analysis, this part was changed over to a formed part from the Conform Next product line. The result: after optimization, the forming blank has a volume of only 9,135 mm³ and a weight of 24.82 g per piece. In addition to the significantly optimized cost due to less material being used in cold forming, this has a considerable impact on the product carbon footprint of the special screw.