www.industryemea.com

01

'22

Written on Modified on

Yokogawa and Mitsubishi Heavy Industries to Undertake AI-enabled Robot System Project for the Nippon Foundation - DeepStar Joint Research & Development Program

Aiming for autonomous operations on offshore platforms.

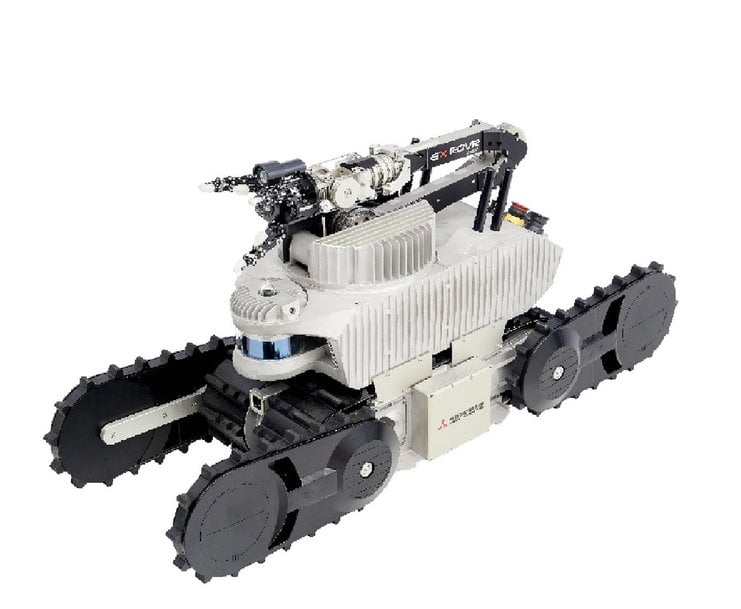

Mitsubishi Heavy Industries' second-generation EX ROVR “ASCENT”

Yokogawa Electric Corporation and Mitsubishi Heavy Industries, Ltd (MHI) announce that they have been selected by the Nippon Foundation, a private, non-profit grant-making organization, to undertake a project as part of the Nippon Foundation - DeepStar*1 Joint Research and Development Program for the promotion of decarbonization in the field of offshore oil and natural gas. The project is scheduled to commence on June 1.

The aim of this project is to develop an automatic inspection system that utilizes robots to identify and predict hazards in offshore facilities. The use of a wide variety of robots to enable unmanned operations and thereby reduce the risk of performing inspections on offshore platforms has long been considered; however, the centralized coordination of individual robots is complex as it requires the management of multiple systems and the data that they acquire. Yokogawa has already been engaged in the research and development of a robot service platform that centralizes the management of multiple robots and seamlessly links them with existing control systems. Leveraging the findings of this R&D, this project will build a communications infrastructure and robot system that is well suited for the environment found on offshore platforms, and utilize an AI application to convert for use in offshore platform operations the image and sound data acquired by robots.

As part of the project, a proof-of-concept test will be carried out using the second-generation EX ROVR plant inspection robot that MHI introduced to the market in April under the name ASCENT. With its explosion-proof features*2, the EX ROVR makes positive contributions to enhancing worker safety, boosting work efficiency, and improving facility operating rates by performing round-the-clock inspections under potentially explosive atmosphere conditions. The robot’s explosion-proof qualification has already been certified both domestically and globally by the International Electrotechnical Commission (IEC)*3 and ATEX certification*4, explosion-proof standards widely adopted in Europe and other regions. These qualifications will enable the EX ROVR’s safe usage under Zone 1 combustible gas conditions.

The adoption of a 6-DOF*5 explosion-proof manipulator with light-equipped camera enables close-up and front-facing photography, from diverse positions, of complexly arranged plant instrumentation. Measurement of gas density, sound recording, and acquisition of thermal images are also possible. In addition, when used in combination with the online application provided as a standard feature, the operator can perform remote setting and management of inspection schedules and confirmation of inspection data. In the event of an incident occurring in the plant, remote monitoring enables swift identification of on-site conditions, thereby contributing to higher plant inspection efficiency and safe, swift resolution of the incident in question.

Yokogawa provides solutions and services to its customers that will enable a digital transformation (DX) in their businesses, and is preparing the way for a future in which industries will make the transition from industrial automation to industrial autonomy (IA2IA). Robotics is a key technology that is paving the way to industrial autonomy. Yokogawa and MHI have already entered into a cooperation agreement regarding the utilization of robots in the oil, gas, and petrochemical industries. With this project, Yokogawa and MHI will jointly research and develop a robot system that is well suited for a variety of environments and situations.

www.yokogawa.com

Yokogawa Electric Corporation and Mitsubishi Heavy Industries, Ltd (MHI) announce that they have been selected by the Nippon Foundation, a private, non-profit grant-making organization, to undertake a project as part of the Nippon Foundation - DeepStar*1 Joint Research and Development Program for the promotion of decarbonization in the field of offshore oil and natural gas. The project is scheduled to commence on June 1.

The aim of this project is to develop an automatic inspection system that utilizes robots to identify and predict hazards in offshore facilities. The use of a wide variety of robots to enable unmanned operations and thereby reduce the risk of performing inspections on offshore platforms has long been considered; however, the centralized coordination of individual robots is complex as it requires the management of multiple systems and the data that they acquire. Yokogawa has already been engaged in the research and development of a robot service platform that centralizes the management of multiple robots and seamlessly links them with existing control systems. Leveraging the findings of this R&D, this project will build a communications infrastructure and robot system that is well suited for the environment found on offshore platforms, and utilize an AI application to convert for use in offshore platform operations the image and sound data acquired by robots.

As part of the project, a proof-of-concept test will be carried out using the second-generation EX ROVR plant inspection robot that MHI introduced to the market in April under the name ASCENT. With its explosion-proof features*2, the EX ROVR makes positive contributions to enhancing worker safety, boosting work efficiency, and improving facility operating rates by performing round-the-clock inspections under potentially explosive atmosphere conditions. The robot’s explosion-proof qualification has already been certified both domestically and globally by the International Electrotechnical Commission (IEC)*3 and ATEX certification*4, explosion-proof standards widely adopted in Europe and other regions. These qualifications will enable the EX ROVR’s safe usage under Zone 1 combustible gas conditions.

The adoption of a 6-DOF*5 explosion-proof manipulator with light-equipped camera enables close-up and front-facing photography, from diverse positions, of complexly arranged plant instrumentation. Measurement of gas density, sound recording, and acquisition of thermal images are also possible. In addition, when used in combination with the online application provided as a standard feature, the operator can perform remote setting and management of inspection schedules and confirmation of inspection data. In the event of an incident occurring in the plant, remote monitoring enables swift identification of on-site conditions, thereby contributing to higher plant inspection efficiency and safe, swift resolution of the incident in question.

Yokogawa provides solutions and services to its customers that will enable a digital transformation (DX) in their businesses, and is preparing the way for a future in which industries will make the transition from industrial automation to industrial autonomy (IA2IA). Robotics is a key technology that is paving the way to industrial autonomy. Yokogawa and MHI have already entered into a cooperation agreement regarding the utilization of robots in the oil, gas, and petrochemical industries. With this project, Yokogawa and MHI will jointly research and develop a robot system that is well suited for a variety of environments and situations.

www.yokogawa.com